| 345° |

| 345° | ||

| Feed |

| Standard Wiring | ||

Pin Number | Color | Pin Number | Color | ||

1: PP Supply (+) | Orange2 | 1: PP Supply (+) | Orange2 | ||

2: Pan Position | Yellow2 | 2: Pan Position | Yellow2 | ||

3: PP Return | Gray2 | 3: PP Return | Gray2 | ||

4: Tilt Position | White/Black2 | 4: Tilt Position | White/Black2 | ||

5: Lens Common | Green2 | 5: NC1 |

| ||

6: Zoom | Blue2 | 6: NC1 |

| ||

7: Focus | Violet2 | 7: NC1 |

| ||

8: Zoom Position | Brown2 | 8: NC1 |

| ||

9: Focus Position | Black2 | 9: NC1 |

| ||

10. | Accessory | White2,3 | 10. | NC1 |

|

11. | Accessory | Red2,3 | 11. | NC1 |

|

12. | Accessory | Yellow2,3 | 12. | NC1 |

|

13: NC1 |

| 13: NC1 |

| ||

14: NC1 |

| 14: NC1 |

| ||

15: NC1 |

| 15: NC1 |

| ||

16: Pan Left | White | 16: Pan Left | White | ||

17: NC1 |

| 17: NC1 |

| ||

18: Pan Right | Violet | 18: Pan Right | Violet | ||

19: P/T Common | Blue | 19: P/T Common | Blue | ||

20: Tilt Up | Brown | 20: Tilt Up | Brown | ||

21: Tilt Down | White/Yellow | 21: Tilt Down | White/Yellow | ||

22: Ground | Green/Yellow2 | 22: Ground | Green/Yellow2 | ||

23: Camera | Black2,4 | 23: NC1 |

| ||

24: Camera | White2,4 | 24: NC1 |

| ||

Notes

1.NC

2.(Color Codes) indicate

3.Apply to 24 volt models only. Pins 10 thru 12 are not used in 110 volt or 220 volt models.

4.(Color Codes) shown are for 24 volt and 110 volt models. For 220 volt models, color codes are (23) Brown, and (24) Blue.

5.The conductors for pins 16 thru 24 (where applicable) on 220 volt models should be isolated from other wiring with reinforced insulation requirements of DIN VDE 0860/05.89, IEC 65. The conductors for pins 16 thru 24 (where applicable) must be

in HAR cord minimum cross sectional area 0.75 mm2 (H05

6.Refer to Figure 6 under Wiring Diagrams for the wiring schematic.

7.Refer to Figure 7 under Wiring Diagrams for the wiring schematic.

8.

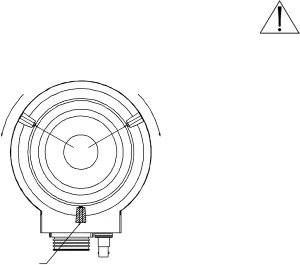

3.8Pan Stops (345° Models)

Locate the three (3) limit stops on the base of the unit. The red limit stop is the Fixed Stop. It is not adjustable and should not be removed. The remaining two (2) stops are called the Pan Stops. These are positioned on each side of the pan switch lever.

The two (2) pan stops are adjustable and secured with a set screw. The screws can be accessed through the hole in the end of each stop. Use a

Top View Of Base

Front

Left | Pan | Right |

(CCW) | Stops | (CW) |

Fixed Stop (Red)

Rear

Figure 3: Pan Stop Locations (345º Models)

4 OPERATION

4.1Manual Pan Operation (345° Models)

The pan stops establish the limits for manual pan. The two

(2)adjustable pan stops may be repositioned or removed depending on the desired operation. The maximum pan range setup is shown in Figure 4.

Caution: Never move or remove the fixed stop. It must always be in place for proper operation of the pan function.

4.2Auto-Pan Operation (345º Models)

Use of the

Note: The pan/tilt controller must be equipped with special current sensing circuitry to operate the

7