Stylus C40UX/C40SX/C20UX/C20SX | Revision A |

2.1.6.2 Capping Mechanism

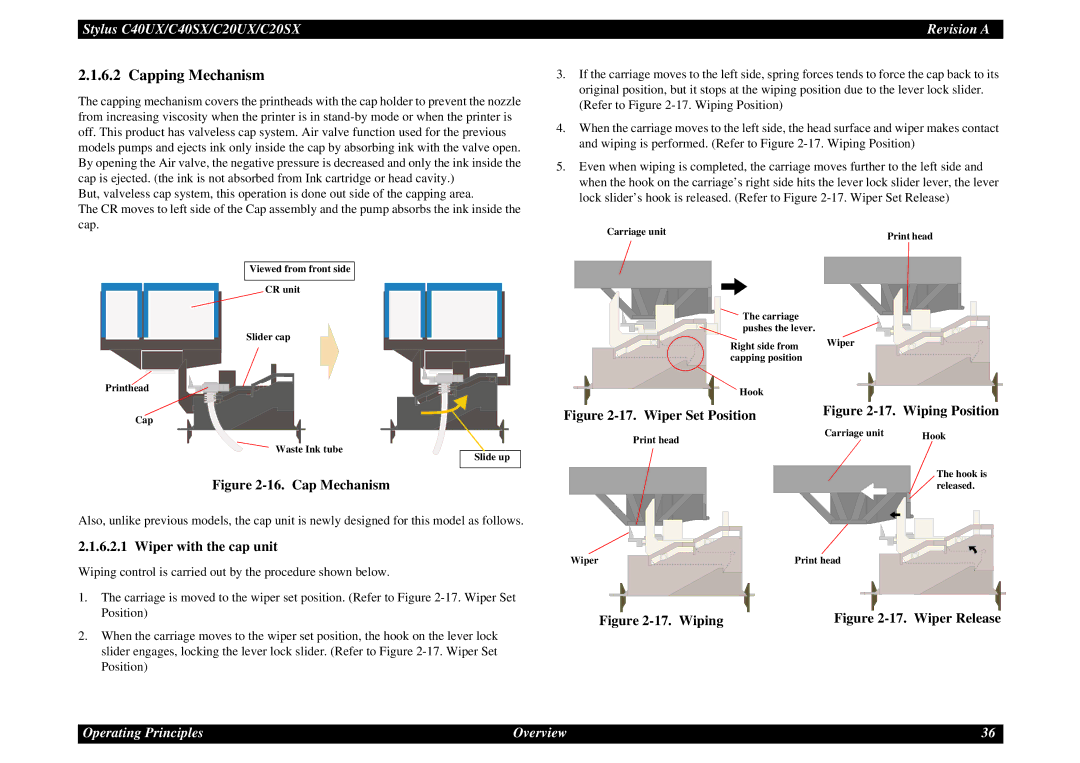

The capping mechanism covers the printheads with the cap holder to prevent the nozzle from increasing viscosity when the printer is in

But, valveless cap system, this operation is done out side of the capping area.

The CR moves to left side of the Cap assembly and the pump absorbs the ink inside the cap.

3.If the carriage moves to the left side, spring forces tends to force the cap back to its original position, but it stops at the wiping position due to the lever lock slider. (Refer to Figure

4.When the carriage moves to the left side, the head surface and wiper makes contact and wiping is performed. (Refer to Figure

5.Even when wiping is completed, the carriage moves further to the left side and when the hook on the carriage’s right side hits the lever lock slider lever, the lever lock slider’s hook is released. (Refer to Figure

Carriage unit | Print head |

|

| Viewed from front side |

|

| CR unit |

|

| The carriage |

|

| pushes the lever. |

|

| Slider cap | Wiper |

| Right side from | |

| capping position |

|

Printhead | Hook |

|

|

|

Cap

Waste Ink tube

Figure 2-16. Cap Mechanism

| Figure | Figure | Wiping Position | |||

|

| Print head | Carriage unit |

| Hook | |

|

|

|

|

| ||

|

|

|

|

|

|

|

Slide up |

|

|

| |||

|

|

|

|

|

| The hook is |

|

|

|

|

|

| |

|

|

|

|

|

| released. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Also, unlike previous models, the cap unit is newly designed for this model as follows.

2.1.6.2.1 Wiper with the cap unit

Wiping control is carried out by the procedure shown below.

1.The carriage is moved to the wiper set position. (Refer to Figure

2.When the carriage moves to the wiper set position, the hook on the lever lock slider engages, locking the lever lock slider. (Refer to Figure

Wiper | Print head |

Figure | Figure |

Operating Principles | Overview | 36 |