Hydra

Limited Warranty & Limitation of Liability

Interference Information

Page

Safety Summary

Do Not Operate in Explosive Atmospheres

Table of Contents

Hydra

General Maintenance

Performance Testing and Calibration

Diagnostic Testing and Troubleshooting 2635A 5A-1

Schematic Diagrams Hydra Starter Calibration Software

List of Tables

5A-19

List of Figures

5A-10

Introduction and Specifications

Hydra

Introduction

Options and Accessories

Operating Instructions

Theory of Operation 2635A

IEEE-488 Option 2620A only Schematic Diagrams

Conventions

Hydra Features

Accessories Description

Specifications

Model

A/2625A Specifications

DC Voltage Inputs Resolution Range

Normal Mode Rejection

Common Mode Rejection

100.00

A/2625A Specifications Thermocouple Inputs Input Impedance

Common Mode and Normal Mode Rejection

Wire Accuracy

Maximum Open Circuit Voltage Maximum Sensor Temperature

0C to 60C Slow Fast

Crest Factor Error Input at Upper Frequency

DC Component Error

Using Channel

Maximum Crest Factor

A/2625A Specifications Ohms Input Range

Resolution Slow Fast

Typical Full Maximum Current Scale Voltage Through Unknown

Input Protection

Function Range Channels

Typical Scanning Rate

Slow Fast

Digital Inputs

Totalizing Inputs

Trigger Inputs

A/2625A Specifications Digital and Alarm Outputs

Real-Time Clock and Calendar

Environmental

General

RS-232-C

2625A Data Storage

A/2625A Specifications 2620A Options IEEE-488 Option -05K

AC Signal Crosstalk in a DC Voltage Channel

AC Signal Crosstalk into an AC Voltage Channel

Typical

AC Signal Crosstalk into a Temperature Channel

Type Worst case Typical

A Specifications

DC Voltage Inputs Resolution Range Slow Fast

A Specifications Input Impedance

Days Slow Year Slow Year Fast

Introduction and Specifications

A Specifications Thermocouple Inputs Input Impedance

300 mV 10 μV 100 μV 30V 10 mV 150/300V 100 mV

Maximum Crest Factor

A Specifications Ohms Input Range

Typical Scanning Rate Function Range Channels

Totalizing Inputs

A Specifications Digital and Alarm Outputs

TX, RX, DTR, DSR, RTS, CTS, GND

Hydra

Theory of Operation 2620A/2625A

Totalizer Input External Trigger Input Circuits

Introduction

Interconnect Diagram

Theory of Operation 2620A/2625A Functional Block Description

A/D Converter PCA

Detailed Circuit Description

Power Supply Circuit Description

Inverter

Power Fail Detection

Microprocessor Memory Map Hexadecimal Address

Device Selected

Display/Keyboard Interface

Eeprom

Digital I/O

Digital Input Threshold

49. A/D Converter PCA

Input Protection

Analog

Simplified

Pin Name

Analog Measurement Processor Pin Descriptions

Function Relays

Analog Measurement Processor Pin Descriptions Name

A3K16

Function Relay States Relay Position A3K17

A3K15

Input HI

Ohms Simplified Schematic

AC Volts

AC Volts Input Signal Dividers Range

Drive Signal

A3Z3 Divider Resistors

Overall Gain

59. A/D Converter

Inguard Microcontroller Circuitry

Input Connector PCA

Main PCA Connector

Display

Display Controller

Power-Up Display Initialization

Display Initialization Modes

Address Decoding

IEEE-488 Interface Option

Theory of Operation 2635A

2A-49

2A-4. Power Supply

2A-1. Introduction

2A-2. Functional Block Description

2A-3. Main PCA Circuitry

2A-4

Functional Block Description

2A-8. A/D Converter PCA

2A-16. Input Connector Assembly

2A-21. Detailed Circuit Description

2A-19. Display PCA

2A-20. Memory Card Interface PCA

2A-23.Power Supply Circuit Description

2A-24.Raw DC Supply

2A-27.Inverter

2A-29.Inverter Inguard Supply

2A-31.Digital Kernel

2A-33.Microprocessor

Signal Name

1. Microprocessor Interrupt Sources 2635A Pin

2A-34.Address Decoding

2A-35.Flash Eprom

2A-37.Serial Communication Guard Crossing

2A-38.Display/Keyboard Interface

Clock Dividers

2A-40.RS-232 Interface

2A-45.Digital and Alarm Output Drivers

2A-42.Digital I/O

2A-43.Digital Input Threshold

2A-44.Digital Input Buffers

2A-48. A/D Converter PCA

2A-47.External Trigger Input Circuits

2A-49.Analog Measurement Processor

2A-21

2A-22

2A-23

2A-50.Input Protection

4. Analog Measurement Processor Pin Descriptions 2635A Name

2A-51.Input Signal Conditioning

5. Function Relay States 2635A Relay Position A3K17

2A-54.Ohms and RTDs

2A-27

2A-55.AC Volts

6. AC Buffer Simplified Schematic 2635A

6. AC Volts Input Signal Dividers 2635A Range

2A-57.Passive and Active Filters

2A-58.A/D Converter

2A-31

2A-60.Channel Selection Circuitry

2A-59.Inguard Microcontroller Circuitry

2A-61.Open Thermocouple Check

2A-62. Input Connector PCA

2A-64.Main PCA Connector

Power Supply A2J1 Pins Nominal Voltage

2A-63. Display PCA

2A-66.Display

2A-65.Front Panel Switches

2A-67.Beeper Drive Circuit

2A-68.Watchdog Timer and Reset Circuit

2A-69.Display Controller

8. Display Initialization Modes 2635A

9. Grid Control Signal Timing 2635A

2A-70. Memory Card Interface PCA

2A-72.Microprocessor Interface

2A-71.Main PCA Connector

2A-73.Memory Card Controller

2A-74.PCMCIA Memory Card Connector

2A-40

Static awareness

Dow Chemical

General Maintenance

Install the Handle and Mounting Brackets

Warranty Repairs and Shipping

General Maintenance

Power Requirements

Required Equipment

Cleaning

Servicing Surface-Mount Assemblies

Line Fuse Replacement

Disassembly Procedures

Remove the Front Panel Assembly

Remove the Instrument Case

Remove Handle and Mounting Brackets

Remove the Display PCA

Disassembly Procedures

Removing the Handle and Handle Mounting Brackets

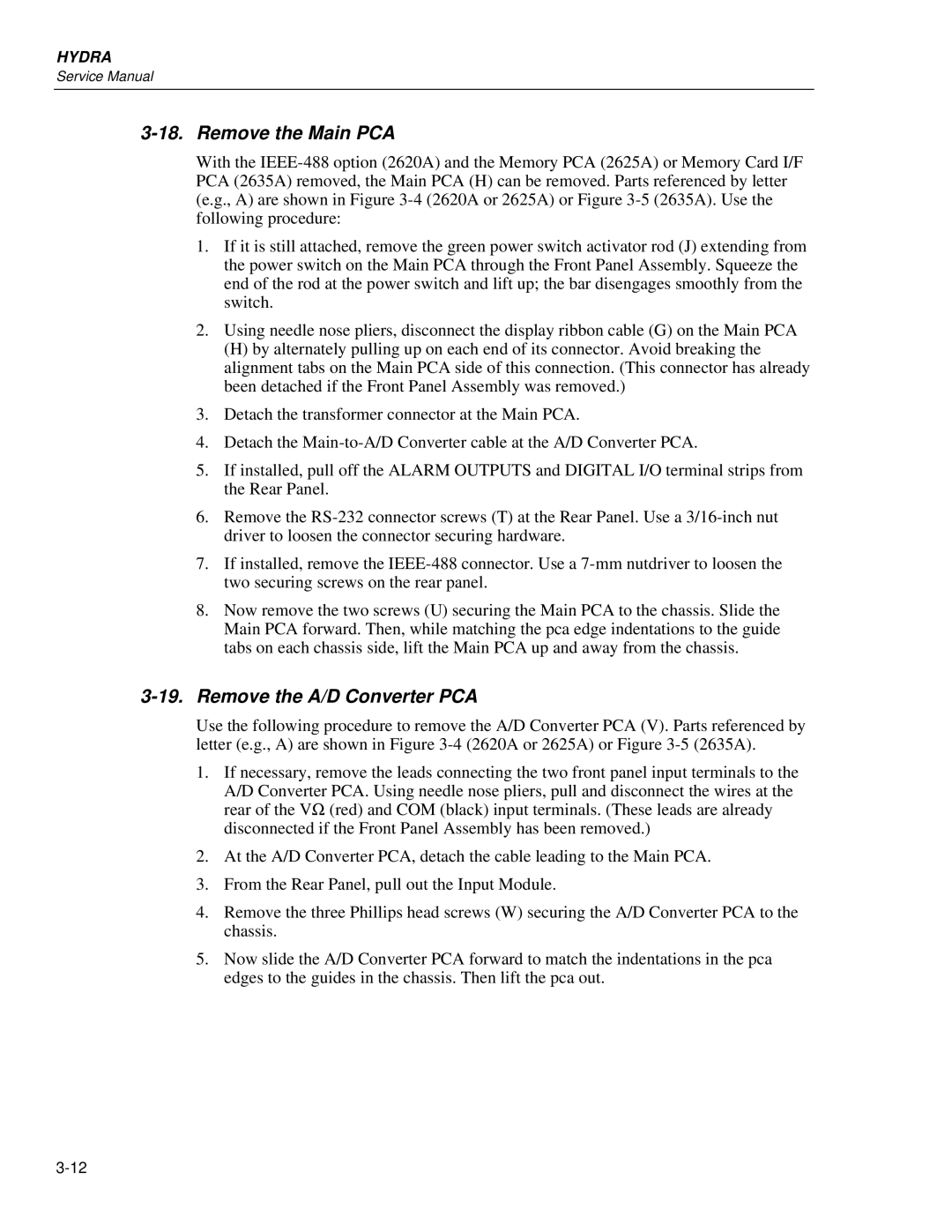

A and 2625A Assembly Details

A Assembly Details

Remove the Memory PCA 2625A Only

Remove the IEEE-488 Option 2620A Only

Remove the Memory Card I/F PCA 2635A Only

Remove the Main PCA

Remove the A/D Converter PCA

Assembly Procedures

Install Miscellaneous Chassis Components

Install the A/D Converter PCA

Disconnect Miscellaneous Chassis Components

Install the IEEE-488 Option 2620A Only

Install the Main PCA

Install the Memory PCA 2625A Only

Install the Memory Card I/F PCA 2635A Only

Assemble the Front Panel Assembly

Install the Front Panel Assembly

Install the Handle and Mounting Brackets

Hydra

Performance Testing and Calibration

Hydra

Recommended Test Equipment Minimum Specifications

Introduction Required Equipment

Instrument Type

Recommended Model

Accuracy Verification Test

Performance Tests

Channel Integrity Test

Performance Tests Voltage, Resistance, and Frequency

Year, 18-28C

Thermocouple Measurement Range Accuracy Test

Function Range Input Level

Terminal Resistance Test

Func 0,VDC,I100MV CR MON 1,0 CR MONVAL? CR

Thermocouple Temperature Accuracy Test

Input Module

11 12 13 14 15 16 17 18 19

11 12 13 14 15 16 17 18 19 3 4 5 6 7 8 9

Thermocouple Information Type Positive Lead Material

Positive Lead Color

Negative Lead Material

Usable Range

RTD Temperature Accuracy Test

Open Thermocouple Response Test

Simulated C Temperature 2620A/2635A

RTD Temperature Accuracy Test Using DIN/IEC

Temperature Accuracy Specifications Year @ 18-28C

Digital Input/Output Verification Tests

Digital Output Test

Digital Input Test

Totalizer Test

Terminal Grounded

Digital Input Values State of Digital Inputs

Totalizer Sensitivity Test

Dedicated Alarm Output Test

2 3 4 5 6 7 Σ + 0 1 2 3 TR

5700A

Calibration

External Trigger Input Test

Performance Testing and Calibration

Using Hydra Starter Calibration Software

Setup Procedure Using Starter

Command

Calibration Mode Computer Interface Commands Description

Calibration Procedure Using Starter

Setup Procedure Using a Terminal

Using a Terminal

Calibration Procedure Using a Terminal

Response

DC Volts Calibration Action

Reference Junction Calibration

10. AC Volts Calibration Action

Concluding Calibration

Terminal Connections to Decade Resistance Source

Hydra Input Module

11 -Wire Ohms Calibration Fixed Resistor Command

Updating 2635A Data Bucket Embedded Instrument Firmware

Using the PC Compatible Firmware Loader Software

12 -Wire Ohms Calibration 5700A Command

Default Instrument Firmware Download Procedure

Setup Procedure for Firmware Download

13. Frequency Calibration Command

Using LD2635 Firmware Loader Directly

Diagnostic Testing and Troubleshooting 2620A/2625A

Failure to Detect Memory PCA Failure to Store Data

Servicing Surface-Mount Assemblies

Error Codes

Each error code is displayed for 2 seconds

Error Error Codes Description

General Troubleshooting Procedures

Preregulated Power Supplies

Test Point Locator, Main PCA A1

Power Supply Troubleshooting

Power Fail Detection

Volt Switching Supply

Raw DC Supply

Volt Switching Supply

Inverter

Hydra

FET Gate Signal

Analog Troubleshooting

Power Supply Test Location Acceptable Range

Power Supply Troubleshooting Guide Symptom

Fault

Test Point Pulses

Test Points, A/D Converter PCA A3, A3U9

A3U9

Microcontroller

DC Volts Troubleshooting

AC Volts Troubleshooting

DC Volts HI Troubleshooting Checkpoint

Signal Description

Ohms Troubleshooting

AC Volts HI Troubleshooting Checkpoint

Ohms HI Troubleshooting Checkpoint

Ohms Open-Circuit Voltage Range

Digital Kernel Troubleshooting

Microprocessor Timing

Digital Input Troubleshooting

Digital and Alarm Output Troubleshooting

Totalizer Troubleshooting

Test Points, Display PCA A2

Display Assembly Troubleshooting

Review

Variations in the Display

Introduction

Calibration Failures

Calibration-Related Components

AC Volts 1 kHz

Ohms

Retrieving Calibration Constants

Replacing the Eeprom A1U1

IEEE-488 Interface PCA A5 Troubleshooting

Memory PCA A6 Troubleshooting

Power-Up Problems

Failure to Detect Memory PCA

Hydra

Diagnostic Testing and Troubleshooting 2635A

Failure to Detect Insertion of Memory Card

5A-1. Introduction

5A-2. Servicing Surface-Mount Assemblies

5A-3. Error Codes

Error

1. Error Codes 2635A Description

5A-4. General Troubleshooting Procedures

1. Error Codes 2635A

2. Preregulated Power Supplies 2635A Preregulated Voltage

Measurement Points

General Troubleshooting Procedures

5A-5. Power Supply Troubleshooting

5A-7. Power Fail Detection

5A-8 -Volt Switching Supply

5A-6. Raw DC Supply

2 -Volt Switching Supply 2635A

5A-9. Inverter

5A-10

5A-10. Analog Troubleshooting

3. Power Supply Troubleshooting Guide 2635A Symptom

Power Supply Nearest Component Acceptable Range

5A-14

5A-15

5A-11. DC Volts Troubleshooting

6. Integrator Output 2635A

5A-12. AC Volts Troubleshooting

5A-13. Ohms Troubleshooting

4. DC Volts HI Troubleshooting 2635A Checkpoint

5. AC Volts HI Troubleshooting 2635A Checkpoint

Voltage 7. Ohms HI Troubleshooting 2635A Checkpoint

5A-14. Digital Kernel Troubleshooting

6. Ohms Open-Circuit Voltage 2635A Range

Output A12 A11 A10

5A-20

5A-15. Digital and Alarm Output Troubleshooting

5A-16. Digital Input Troubleshooting

5A-22

5A-17. Totalizer Troubleshooting

5A-18. Display Assembly Troubleshooting

5A-24

9. Display Controller to Microprocessor Signals 2635A

10. Display Test Pattern #1 2635A

5A-19. Variations in the Display

5A-21. Introduction

5A-20. Calibration Failures

5A-22. Calibration-Related Components

5A-28

5A-23. Retrieving Calibration Constants

5A-24. Replacing the Flash Memory A1U14 and A1U16

5A-26. Power-Up Problems

5A-25. Memory Card I/F PCA A6 Troubleshooting

5A-27. Failure to Detect Memory Card I/F PCA

5A-29. Failure to Power Card / Illuminate the Busy Led

5A-30. Failure to Illuminate the Battery Led

Battery LED

5A-28. Failure to Detect Insertion of Memory Card

5A-31. Failure to Write to Memory Card

5A-32. Write/Read Memory Card Test Destructive

Memory card test passed without detecting any errors

5A-34

List of Replaceable Parts

Hydra

How to Obtain Parts

Manual Status Information

Newer Instruments

Service Centers

Revision

List of Replaceable Parts Service Centers

A/2625A Final Assembly

TM1 TM2 TM3 TM4 TM5 TM6

2620A/2625A T&B

Bottom View

Top View

S58f.eps

A Final Assembly

TM1 TM2 TM3 TM4 TM5

2635A T&B

Part of W2 MP102 H52 Cable Assembly

T1 Ref H52

S62f.eps

A/2625A A1 Main PCA

CR5,CR6

Reference Description Designator

VR1 VR2 VR3 VR4

2620A-1601

A A1 Main PCA

CAP,AL,10UF,+-20%,63V,SOLV Prooof

MP101 Q1-3,Q10 Q4-6 Q7,Q8 R1,R11,R12 R22,R25,R45

INDUCTOR,FXD,DUAL,EE24-25,0.4MH,1.2A

2635A-1601

WIRE,JUMPER,TEF,22AWG,WHT,.300

A2 Display PCA

CKT

A3 A/D Converter PCA

Reference Description Designator Fluke Stock Tot Qty

Reference Description Fluke Stock Designator

K3, K5-K14 Relay Polarity

A4 Analog Input PCA

Reference Description Fluke Stock Tot Qty Designator

2620A-1604

A5 Option -05 IEEE-488 Interface PCA

A5 IEEE-488 Interface PCA Option

A A6 Memory PCA

2625A-1606

10 a A6 Memory Card I/F PCA

2635A-1606

Hydra

IEEE-488 Option

Hydra

IEEE-488 PCA Detailed Circuit Description 2620A Only

Theory of Operation

Functional Block Description

Main PCA Connector

IEEE-488 Controller

Removing the IEEE-488 Option

IEEE-488 Transceivers/Connector

IEEE-488 Transceiver Control

Installation

Performance Testing

Installing the IEEE-488 Option

Troubleshooting

Communication Problems

Failure to Select IEEE-488 Option

Failure to Handshake on IEEE-488 Bus

Schematic Diagram

List of Replaceable Parts

Hydra

Schematic Diagrams

Hydra

Schematic Diagrams

Power Supply PIN Numbers DES

RAW Supply

2620A-1001

U S E D

Reference Designations Lasted Used Not Used

A1 Main PCA 2635A

2635A-1001

2635A-1001

2635A-1001

Control

External Trigger Totalizer Inputs

CKT

2620A-1002

S91c.eps

2620A-1003

S82c.eps

S83c.eps

S92f.eps

2620A-1004

A5 IEEE-488 Interface PCA 2620A Only

1V dc

A6 Memory PCA 2625A

A6U1 A6U2 A6U3 A6U4 A6U5 A6U6 A6U7 A6U8 2625A-1006

Reference Designations

Lasted Used Not Used 0V dc

2635A-1006

Schematic Diagrams