1 |

Programming Basics

The most important ingredients in creating a successful PLC program are a thorough understanding of the application itself, and a good measure of common sense.

The first step in creating a PLC application program is planning.

hThe desired sequence of program actions is determined.

hAll of the required inputs and outputs are identified and listed.

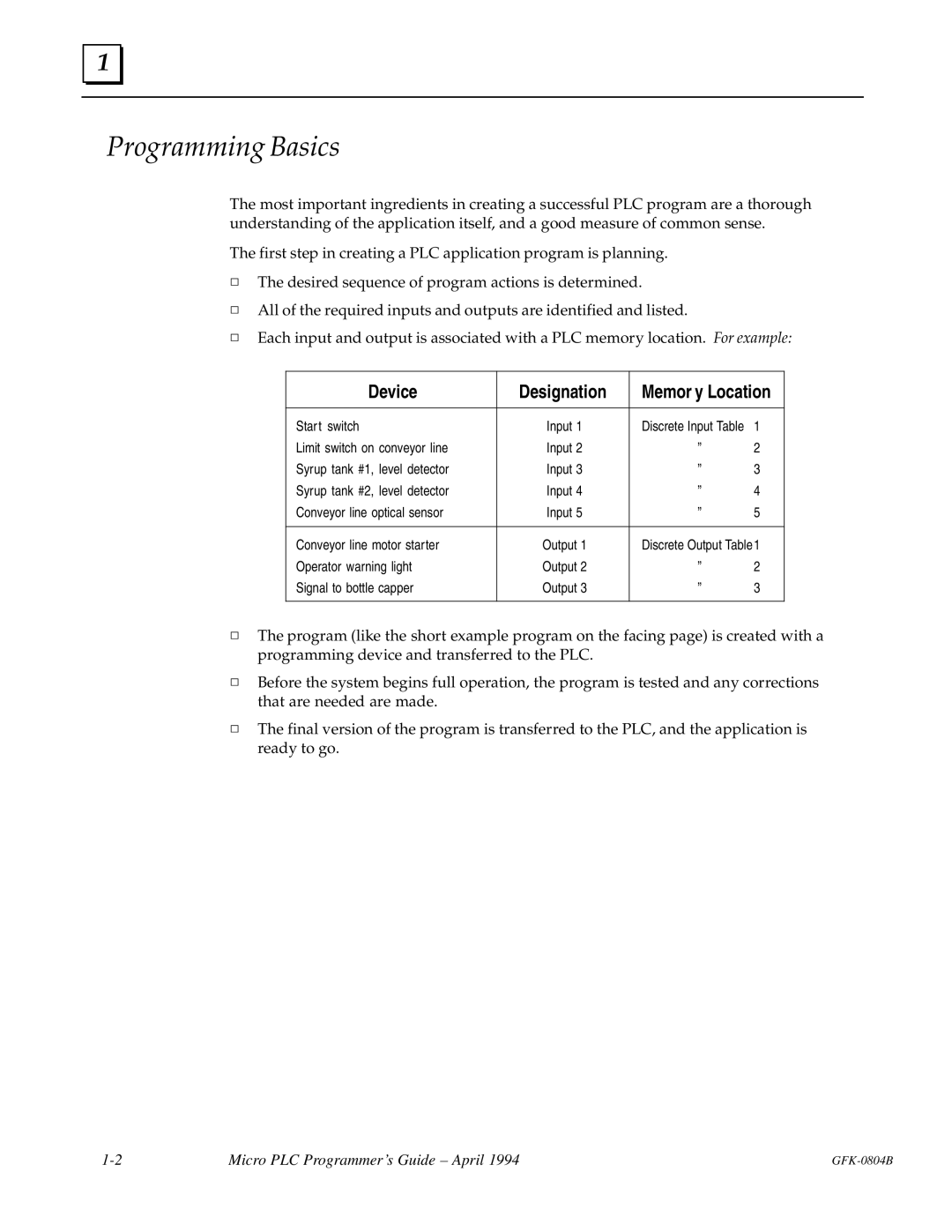

hEach input and output is associated with a PLC memory location. For example:

Device | Designation | Memor y Location | |

|

|

|

|

Start switch | Input 1 | Discrete Input Table | 1 |

Limit switch on conveyor line | Input 2 | º | 2 |

Syrup tank #1, level detector | Input 3 | º | 3 |

Syrup tank #2, level detector | Input 4 | º | 4 |

Conveyor line optical sensor | Input 5 | º | 5 |

|

|

| |

Conveyor line motor starter | Output 1 | Discrete Output Table1 | |

Operator warning light | Output 2 | º | 2 |

Signal to bottle capper | Output 3 | º | 3 |

|

|

|

|

hThe program (like the short example program on the facing page) is created with a programming device and transferred to the PLC.

hBefore the system begins full operation, the program is tested and any corrections that are needed are made.

hThe final version of the program is transferred to the PLC, and the application is ready to go.

Micro PLC Programmer's Guide ± April 1994 |