Battery Installation

2.4.2Fitting the Batteries

1.In general, at least 10mm (3/8") must be left unobstructed on all vertical sides of the battery blocks to permit free air movement around the cells.

2.Clearance should be allowed between the top of the cells and the underside of the shelf above (this is necessary for monitoring and servicing the cells).

3.When installing the batteries on racks always work from the bottom shelf upwards to prevent raising the centre of gravity.

2.4.3Connecting the Battery

1.When the battery cabinet is installed on a raised floor the battery power cables and optional circuit breaker control cables can be routed to the UPS cabinet via the floor of the cabinet. If the UPS and battery cabinet are located adjacent to each other and located on a solid floor these cables can be passed between the cabinets via the lifting apertures located in the lower sides of the cabinets.

2.In general it is recommended that the

3.An insulating shroud should be fitted to each terminal after its connection has been made.

4.When connecting the cables between the battery string ends to the optional circuit breaker always connect the circuit breaker end of the cable first.

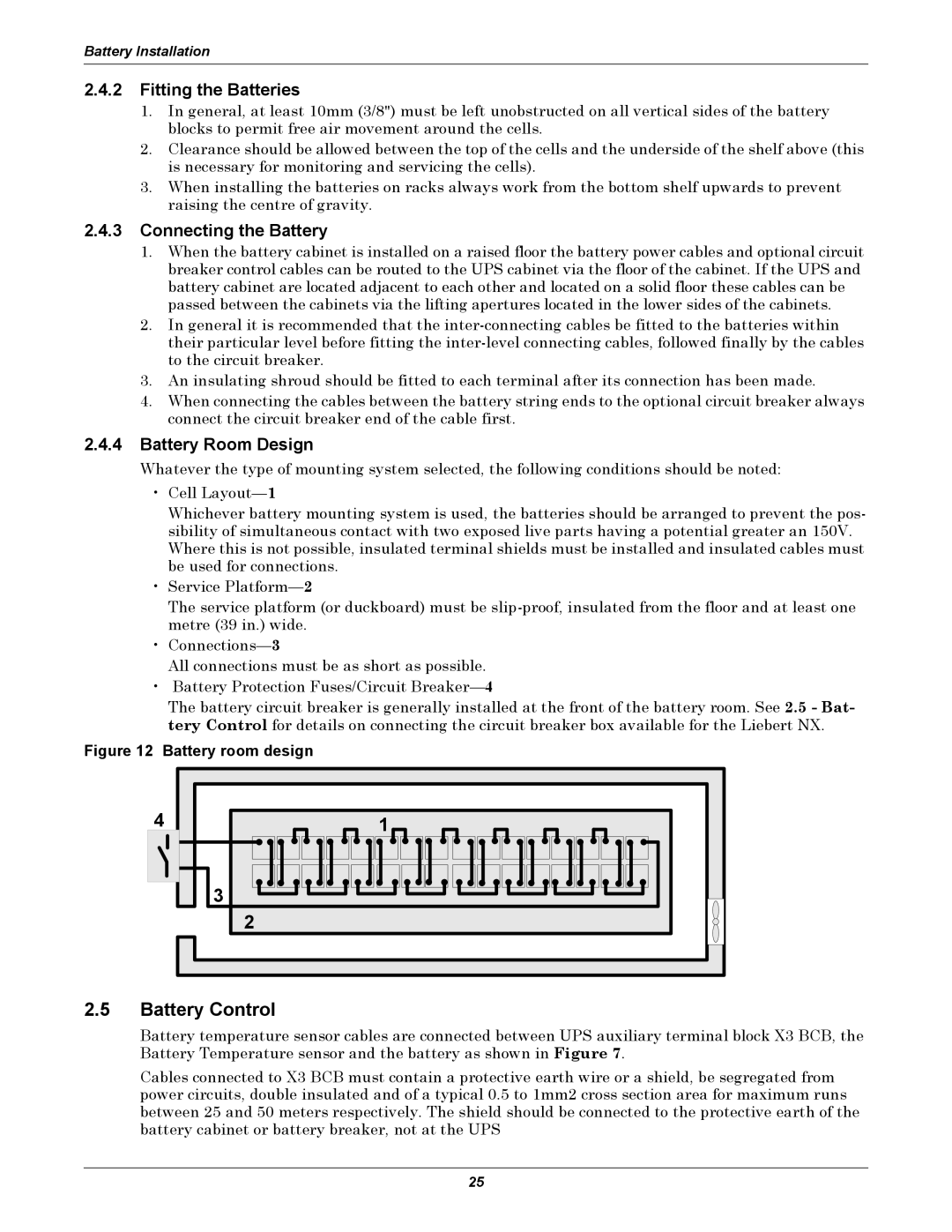

2.4.4Battery Room Design

Whatever the type of mounting system selected, the following conditions should be noted:

•Cell

Whichever battery mounting system is used, the batteries should be arranged to prevent the pos- sibility of simultaneous contact with two exposed live parts having a potential greater an 150V. Where this is not possible, insulated terminal shields must be installed and insulated cables must be used for connections.

•Service

The service platform (or duckboard) must be

•

All connections must be as short as possible.

•Battery Protection Fuses/Circuit

The battery circuit breaker is generally installed at the front of the battery room. See 2.5 - Bat- tery Control for details on connecting the circuit breaker box available for the Liebert NX.

Figure 12 Battery room design

4

1

3![]()

![]()

![]()

![]()

![]()

2

2.5Battery Control

Battery temperature sensor cables are connected between UPS auxiliary terminal block X3 BCB, the Battery Temperature sensor and the battery as shown in Figure 7.

Cables connected to X3 BCB must contain a protective earth wire or a shield, be segregated from power circuits, double insulated and of a typical 0.5 to 1mm2 cross section area for maximum runs between 25 and 50 meters respectively. The shield should be connected to the protective earth of the battery cabinet or battery breaker, not at the UPS

25