Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OPERATION |

CONTROLS AND SETTINGS

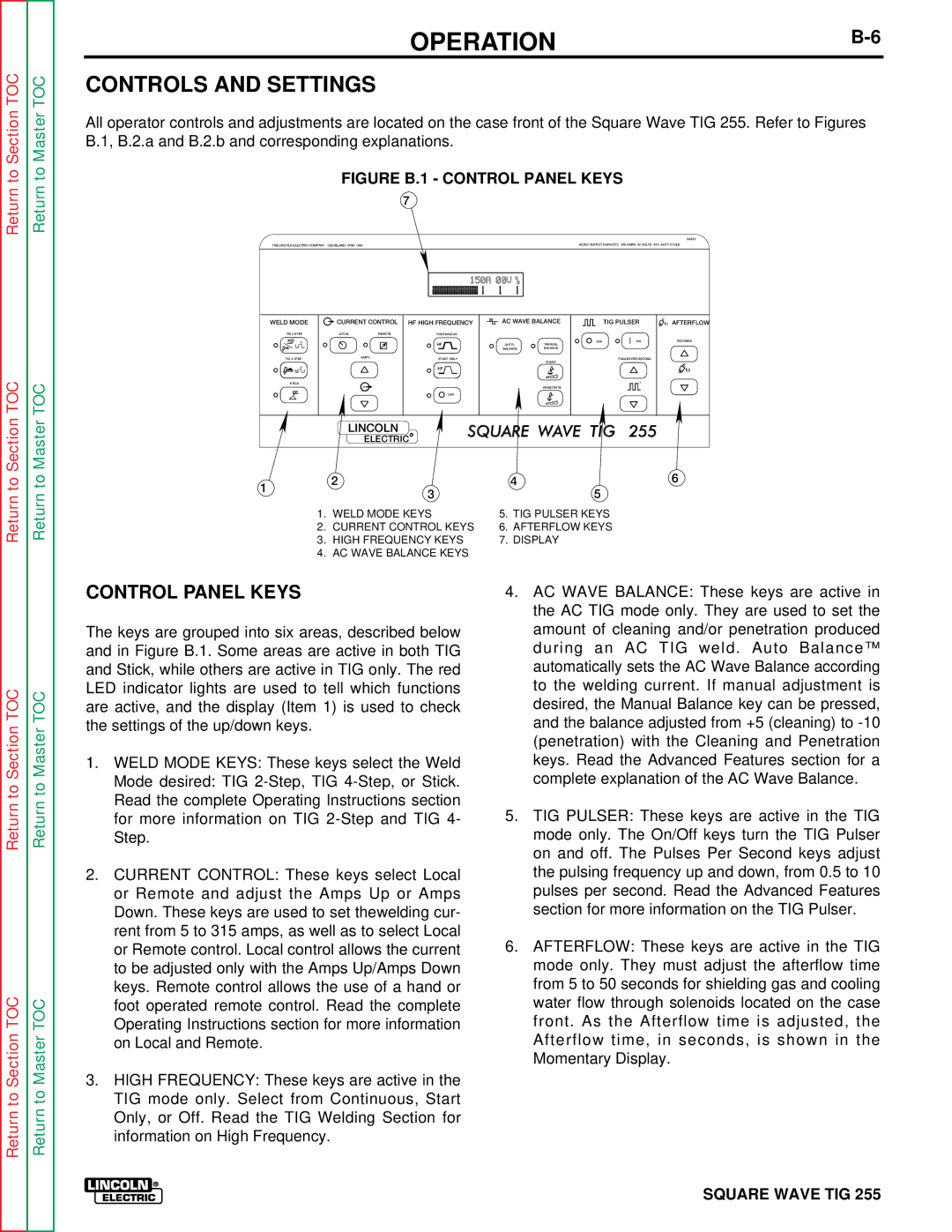

All operator controls and adjustments are located on the case front of the Square Wave TIG 255. Refer to Figures B.1, B.2.a and B.2.b and corresponding explanations.

FIGURE B.1 - CONTROL PANEL KEYS

7

G2612

THE LINCOLN ELECTRIC COMPANY CLEVELAND, OHIO USA |

| AC/DC OUTPUT CAPACITY: 255 AMPS 30 VOLTS 40% DUTY CYCLE |

|

|

|

|

|

|

WELD MODE | CURRENT CONTROL | HF HIGH FREQUENCY | AC WAVE BALANCE | TIG PULSER | 2 AFTERFLOW | ||

TIG | LOCAL | REMOTE | CONTINUOUS |

|

|

|

|

|

|

| HF |

| OFF | ON | SECONDS |

|

|

| AUTO- | MANUAL |

|

| |

|

|

|

| BALANCE | BALANCE |

|

|

TIG |

| AMPS | START ONLY |

|

| PULSES PER SECOND |

|

|

|

|

|

| CLEAN |

|

|

|

|

| HF |

|

|

| 2 |

STICK |

|

|

|

|

| f |

|

|

| A |

|

| PENETRATE |

|

|

|

|

| OFF |

|

|

|

|

LINCOLN

R

ELECTRIC

1 | 2 |

| 4 | 6 |

3 |

| 5 |

| |

|

|

| ||

1. | WELD MODE KEYS | 5. | TIG PULSER KEYS |

|

2. | CURRENT CONTROL KEYS | 6. | AFTERFLOW KEYS |

|

3. | HIGH FREQUENCY KEYS | 7. | DISPLAY |

|

4. | AC WAVE BALANCE KEYS |

|

|

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

CONTROL PANEL KEYS

The keys are grouped into six areas, described below and in Figure B.1. Some areas are active in both TIG and Stick, while others are active in TIG only. The red LED indicator lights are used to tell which functions are active, and the display (Item 1) is used to check the settings of the up/down keys.

1.WELD MODE KEYS: These keys select the Weld

Mode desired: TIG

2.CURRENT CONTROL: These keys select Local or Remote and adjust the Amps Up or Amps Down. These keys are used to set thewelding cur- rent from 5 to 315 amps, as well as to select Local or Remote control. Local control allows the current to be adjusted only with the Amps Up/Amps Down keys. Remote control allows the use of a hand or foot operated remote control. Read the complete Operating Instructions section for more information on Local and Remote.

3.HIGH FREQUENCY: These keys are active in the TIG mode only. Select from Continuous, Start Only, or Off. Read the TIG Welding Section for information on High Frequency.

4.AC WAVE BALANCE: These keys are active in the AC TIG mode only. They are used to set the amount of cleaning and/or penetration produced during an AC TIG weld. Auto Balance™ automatically sets the AC Wave Balance according to the welding current. If manual adjustment is desired, the Manual Balance key can be pressed, and the balance adjusted from +5 (cleaning) to

5.TIG PULSER: These keys are active in the TIG mode only. The On/Off keys turn the TIG Pulser on and off. The Pulses Per Second keys adjust the pulsing frequency up and down, from 0.5 to 10 pulses per second. Read the Advanced Features section for more information on the TIG Pulser.

6.AFTERFLOW: These keys are active in the TIG mode only. They must adjust the afterflow time from 5 to 50 seconds for shielding gas and cooling water flow through solenoids located on the case front. As the Afterflow time is adjusted, the Afterflow time, in seconds, is shown in the Momentary Display.