Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

| TROUBLESHOOTING & REPAIR |

| ||||||||||

Observe Safety Guidelines |

|

|

| TROUBLESHOOTING GUIDE | |||||||||

detailed in the beginning of this manual. |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||

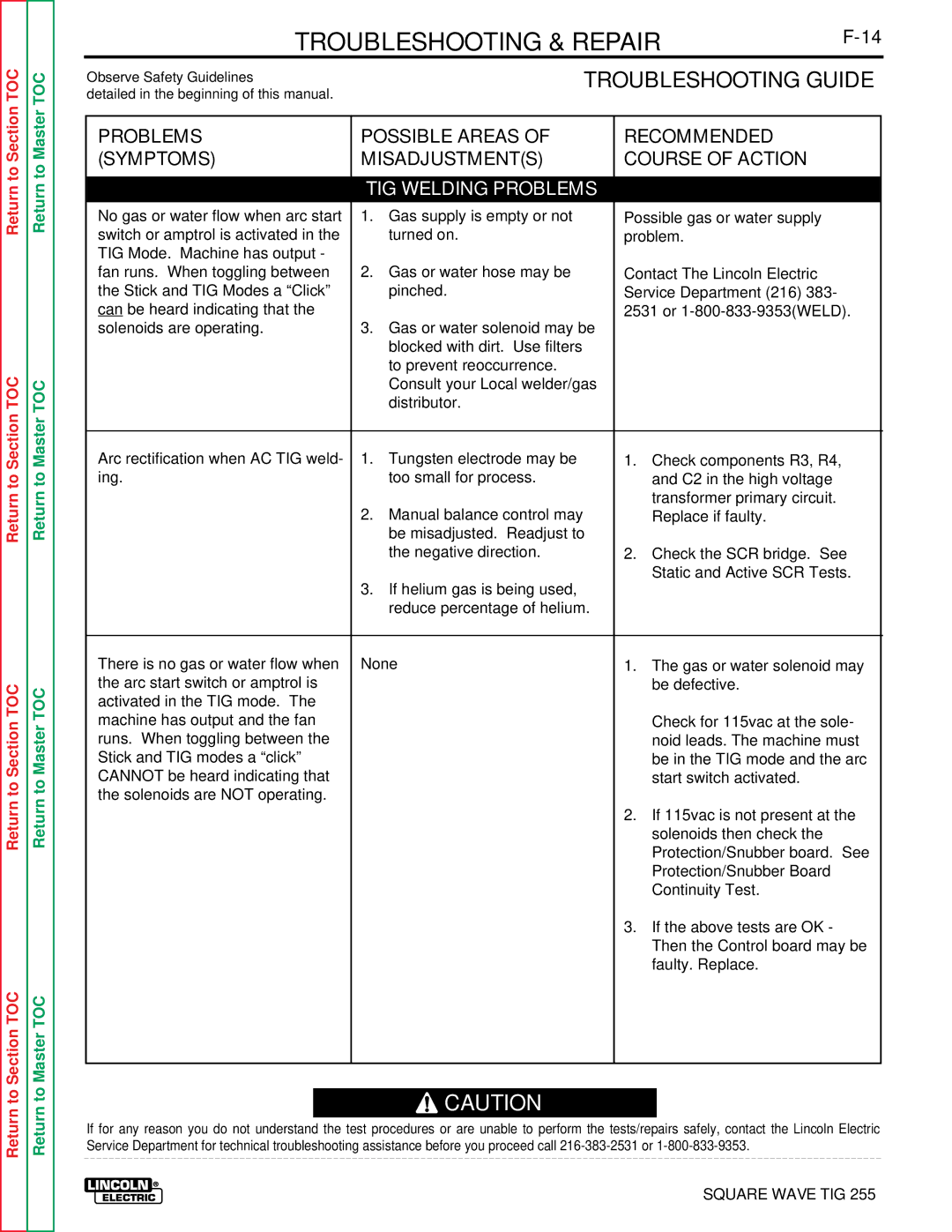

| PROBLEMS | POSSIBLE AREAS OF |

| RECOMMENDED |

|

|

| ||||||

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

|

|

| COURSE OF ACTION |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| TIG WELDING PROBLEMS |

|

|

|

|

|

|

| |

| No gas or water flow when arc start |

|

| 1. Gas supply is empty or not |

|

|

| Possible gas or water supply |

|

|

| ||

| switch or amptrol is activated in the |

|

| turned on. |

|

|

| problem. |

|

|

| ||

| TIG Mode. Machine has output - |

|

|

|

|

|

|

|

|

|

|

| |

| fan runs. When toggling between |

|

| 2. Gas or water hose may be |

|

|

| Contact The Lincoln Electric |

|

|

| ||

| the Stick and TIG Modes a “Click” |

|

| pinched. |

|

|

| Service Department (216) 383- |

|

|

| ||

| can be heard indicating that the |

|

|

|

|

|

| 2531 or |

|

| |||

| solenoids are operating. |

|

| 3. Gas or water solenoid may be |

|

|

|

|

|

| |||

|

|

|

|

| blocked with dirt. Use filters |

|

|

|

|

|

|

|

|

|

|

|

|

| to prevent reoccurrence. |

|

|

|

|

|

|

|

|

|

|

|

|

| Consult your Local welder/gas |

|

|

|

|

|

| ||

|

|

|

|

| distributor. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Arc rectification when AC TIG weld- |

|

| 1. Tungsten electrode may be |

|

|

| 1. Check components R3, R4, |

|

|

| ||

| ing. |

|

| too small for process. |

|

|

| and C2 in the high voltage |

|

|

| ||

|

|

|

|

| 2. Manual balance control may |

|

|

| transformer primary circuit. |

|

|

| |

|

|

|

|

|

|

|

| Replace if faulty. |

|

|

| ||

|

|

|

|

| be misadjusted. Readjust to |

|

|

|

|

|

| ||

|

|

|

|

| the negative direction. |

|

|

| 2. Check the SCR bridge. See |

|

| ||

|

|

|

|

| 3. If helium gas is being used, |

|

|

| Static and Active SCR Tests. |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| reduce percentage of helium. |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |||

| There is no gas or water flow when |

|

| None |

|

|

| 1. The gas or water solenoid may |

|

| |||

| the arc start switch or amptrol is |

|

|

|

|

|

| be defective. |

|

|

| ||

| activated in the TIG mode. The |

|

|

|

|

|

|

|

|

|

|

| |

| machine has output and the fan |

|

|

|

|

|

| Check for 115vac at the sole- |

|

| |||

| runs. When toggling between the |

|

|

|

|

|

| noid leads. The machine must |

|

| |||

| Stick and TIG modes a “click” |

|

|

|

|

|

| be in the TIG mode and the arc |

|

| |||

| CANNOT be heard indicating that |

|

|

|

|

|

| start switch activated. |

|

|

| ||

| the solenoids are NOT operating. |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| 2. If 115vac is not present at the |

|

| ||

|

|

|

|

|

|

|

|

| solenoids then check the |

|

|

| |

|

|

|

|

|

|

|

|

| Protection/Snubber board. See |

|

| ||

|

|

|

|

|

|

|

|

| Protection/Snubber Board |

|

|

| |

|

|

|

|

|

|

|

|

| Continuity Test. |

|

|

| |

|

|

|

|

|

|

|

|

| 3. If the above tests are OK - |

|

|

| |

|

|

|

|

|

|

|

|

| Then the Control board may be |

|

| ||

|

|

|

|

|

|

|

|

| faulty. Replace. |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call