Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

|

|

|

|

|

| OPERATION |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

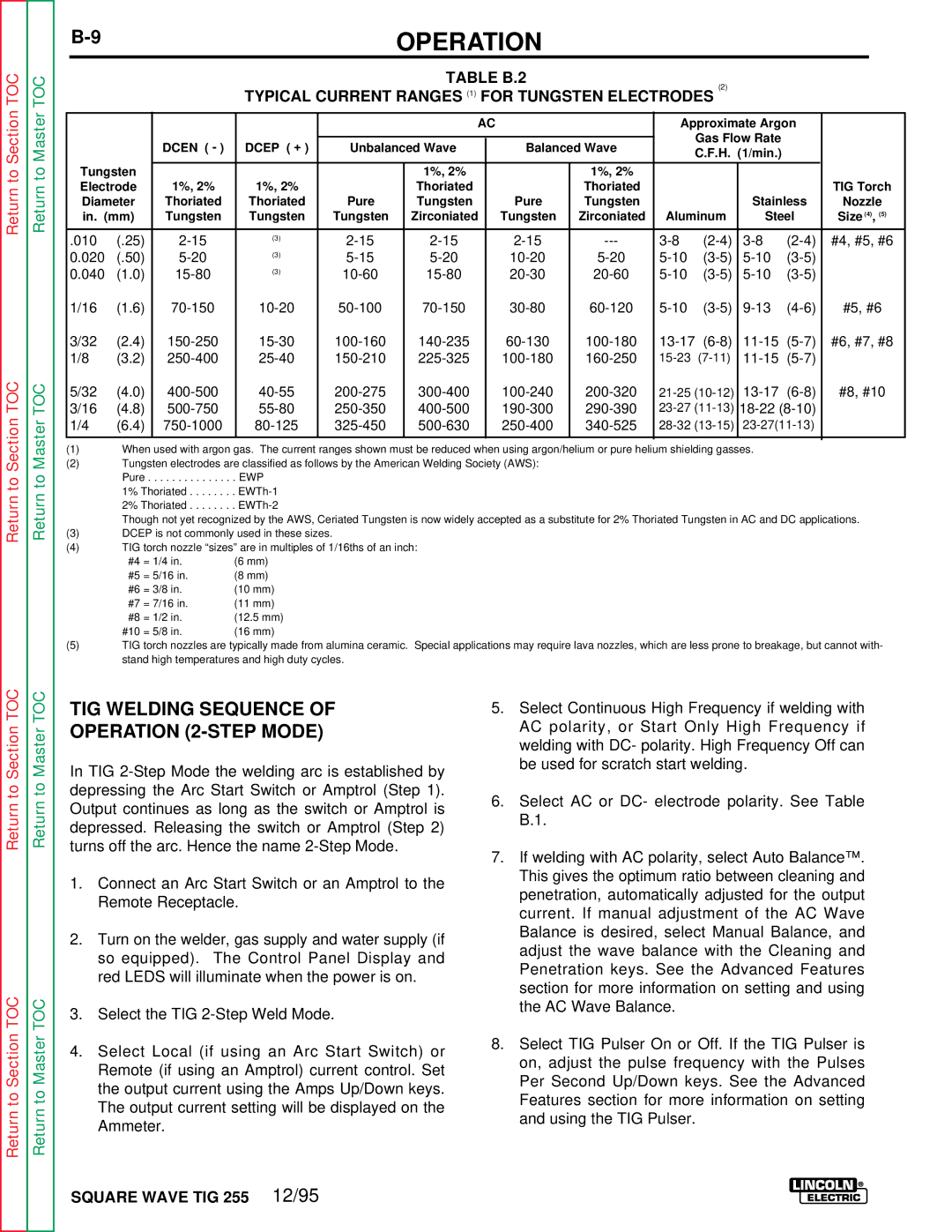

| TABLE B.2 |

|

|

| (2) |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| TYPICAL CURRENT RANGES (1) FOR TUNGSTEN ELECTRODES |

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| AC |

|

|

| Approximate Argon |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Gas Flow Rate |

|

|

|

| |

|

|

|

| DCEN ( - ) | DCEP ( + ) | Unbalanced Wave |

| Balanced Wave |

|

| C.F.H. (1/min.) |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Tungsten |

|

|

|

|

| 1%, 2% |

|

| 1%, 2% |

|

|

|

|

|

|

|

| |

| Electrode |

| 1%, 2% | 1%, 2% |

|

| Thoriated |

|

| Thoriated |

|

|

|

|

| TIG Torch |

| ||

| Diameter |

| Thoriated | Thoriated | Pure |

| Tungsten |

| Pure | Tungsten |

|

|

| Stainless | Nozzle |

| |||

| in. (mm) |

| Tungsten | Tungsten | Tungsten |

| Zirconiated |

| Tungsten | Zirconiated |

| Aluminum | Steel | Size (4), (5) |

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| .010 | (.25) |

| (3) |

|

| #4, #5, #6 |

| |||||||||||

| 0.020 | (.50) |

| (3) |

|

|

|

|

| ||||||||||

| 0.040 | (1.0) |

|

|

|

|

|

| |||||||||||

|

| (3) |

|

|

|

|

| ||||||||||||

| 1/16 | (1.6) |

|

|

| #5, #6 |

| ||||||||||||

| 3/32 | (2.4) |

|

|

| #6, #7, #8 |

| ||||||||||||

| 1/8 | (3.2) |

|

|

|

|

|

| |||||||||||

| 5/32 | (4.0) |

|

|

| #8, #10 |

| ||||||||||||

| 3/16 | (4.8) |

|

|

|

|

|

| |||||||||||

| 1/4 | (6.4) |

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1)When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shielding gasses.

(2)Tungsten electrodes are classified as follows by the American Welding Society (AWS): Pure . . . . . . . . . . . . . . . EWP

1% Thoriated . . . . . . . .

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC and DC applications.

(3)DCEP is not commonly used in these sizes.

(4)TIG torch nozzle “sizes” are in multiples of 1/16ths of an inch:

#4 | = 1/4 in. | (6 mm) |

#5 | = 5/16 in. | (8 mm) |

#6 | = 3/8 in. | (10 mm) |

#7 | = 7/16 in. | (11 mm) |

#8 | = 1/2 in. | (12.5 mm) |

#10 | = 5/8 in. | (16 mm) |

(5)TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to breakage, but cannot with- stand high temperatures and high duty cycles.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TIG WELDING SEQUENCE OF

OPERATION (2-STEP MODE)

In TIG

1.Connect an Arc Start Switch or an Amptrol to the Remote Receptacle.

2.Turn on the welder, gas supply and water supply (if so equipped). The Control Panel Display and red LEDS will illuminate when the power is on.

3.Select the TIG

4.Select Local (if using an Arc Start Switch) or Remote (if using an Amptrol) current control. Set the output current using the Amps Up/Down keys. The output current setting will be displayed on the Ammeter.

5.Select Continuous High Frequency if welding with AC polarity, or Start Only High Frequency if welding with DC- polarity. High Frequency Off can be used for scratch start welding.

6.Select AC or DC- electrode polarity. See Table B.1.

7.If welding with AC polarity, select Auto Balance™. This gives the optimum ratio between cleaning and penetration, automatically adjusted for the output current. If manual adjustment of the AC Wave Balance is desired, select Manual Balance, and adjust the wave balance with the Cleaning and Penetration keys. See the Advanced Features section for more information on setting and using the AC Wave Balance.

8.Select TIG Pulser On or Off. If the TIG Pulser is on, adjust the pulse frequency with the Pulses Per Second Up/Down keys. See the Advanced Features section for more information on setting and using the TIG Pulser.