INSTALLATION |

Return to Section TOC

Section TOC

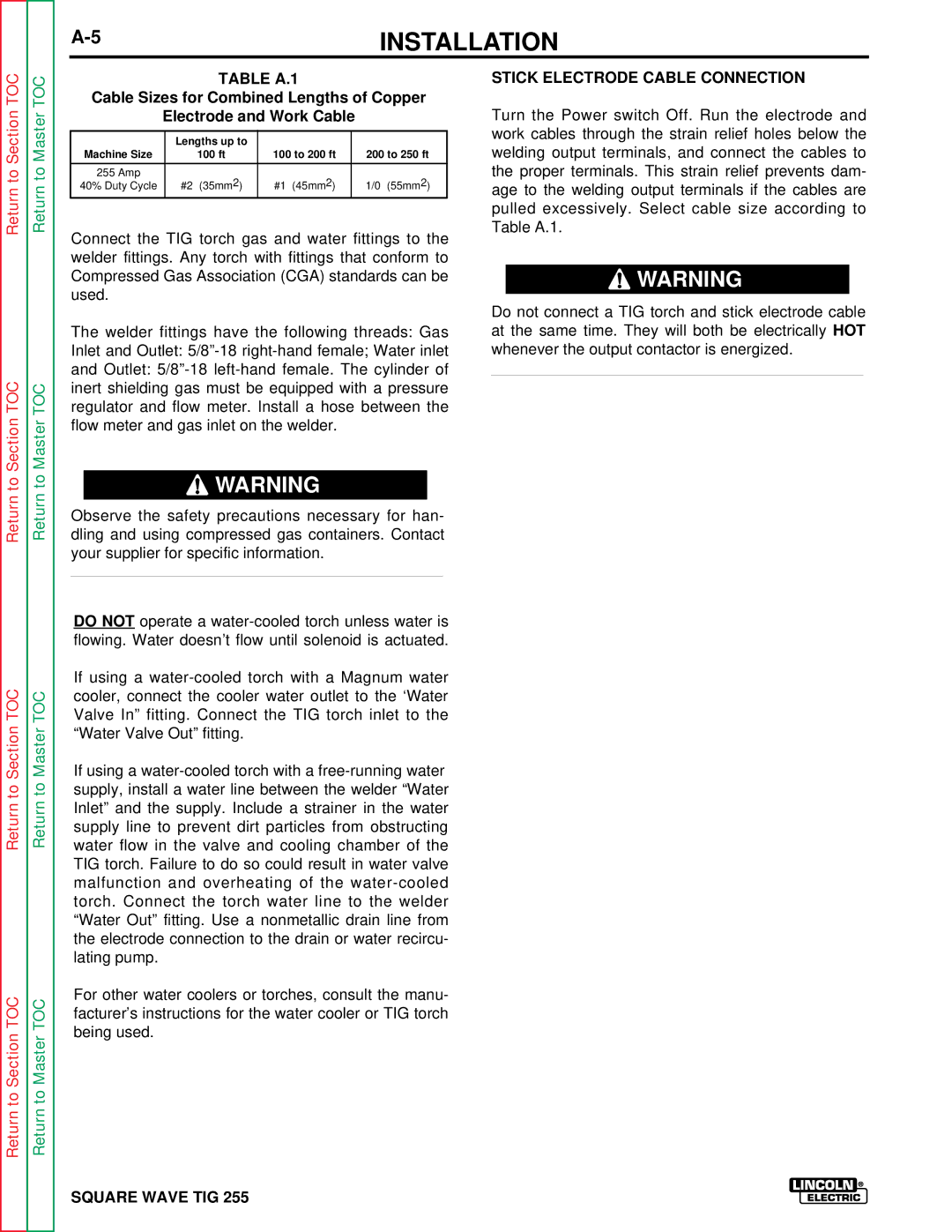

TABLE A.1

Cable Sizes for Combined Lengths of Copper

Electrode and Work Cable

| Lengths up to |

|

|

|

Machine Size | 100 ft | 100 to 200 ft | 200 to 250 ft |

|

|

|

|

|

|

|

|

|

|

|

255 Amp | #2 (35mm2) | #1 (45mm2) | 1/0 (55mm2) |

|

40% Duty Cycle |

| |||

|

|

|

|

|

Connect the TIG torch gas and water fittings to the welder fittings. Any torch with fittings that conform to Compressed Gas Association (CGA) standards can be used.

The welder fittings have the following threads: Gas

Inlet and Outlet:

and Outlet:

STICK ELECTRODE CABLE CONNECTION

Turn the Power switch Off. Run the electrode and work cables through the strain relief holes below the welding output terminals, and connect the cables to the proper terminals. This strain relief prevents dam- age to the welding output terminals if the cables are pulled excessively. Select cable size according to Table A.1.

![]() WARNING

WARNING

Do not connect a TIG torch and stick electrode cable at the same time. They will both be electrically HOT whenever the output contactor is energized.

___________________________________________

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

![]() WARNING

WARNING

Observe the safety precautions necessary for han- dling and using compressed gas containers. Contact

your supplier for specific information.

___________________________________________

DO NOT operate a

If using a

If using a

For other water coolers or torches, consult the manu- facturer’s instructions for the water cooler or TIG torch being used.