Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| TROUBLESHOOTING & REPAIR |

|

| |||||||||

| TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines | ||||||||

|

|

|

|

|

|

|

|

|

| detailed in the beginning of this manual. | ||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||

|

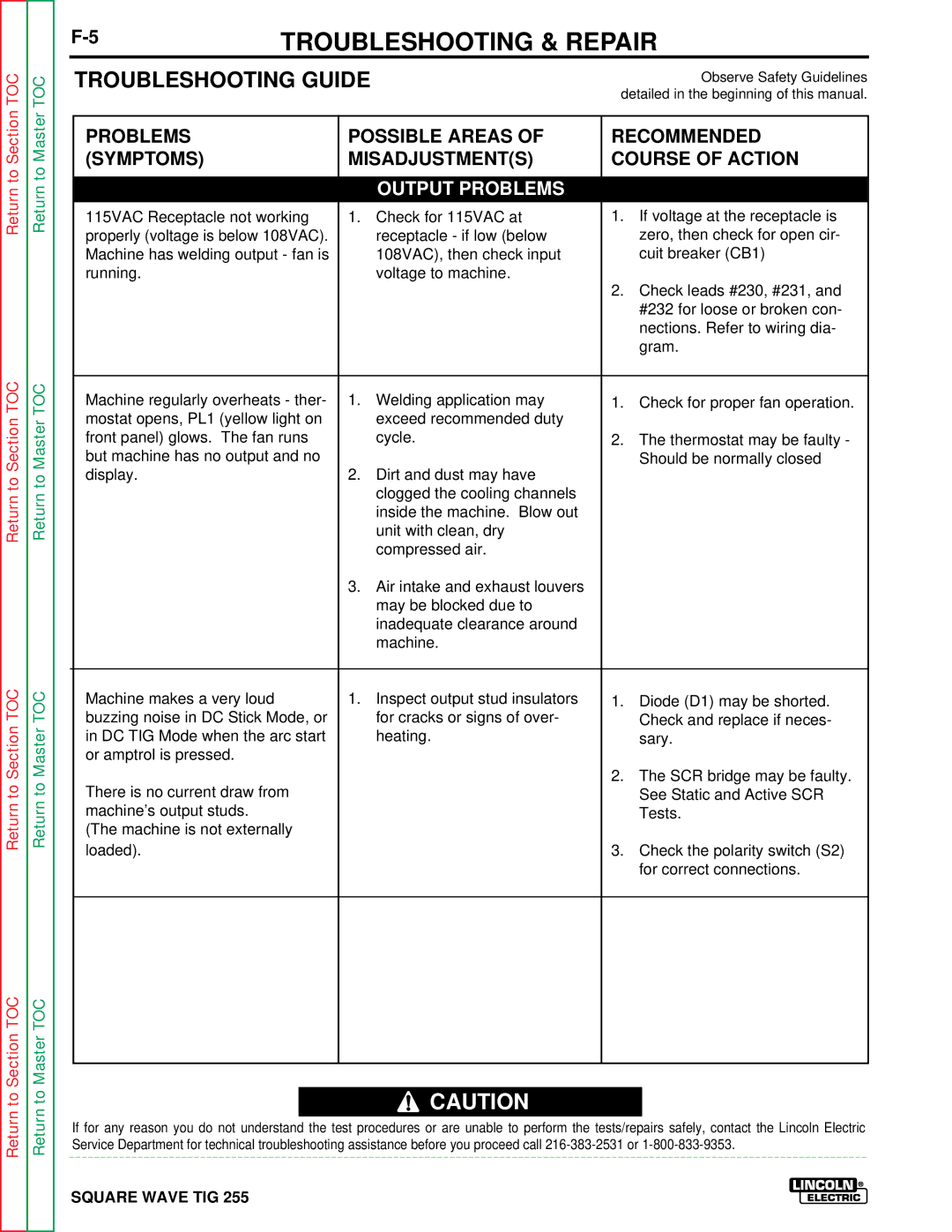

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED | |||||||

|

| (SYMPTOMS) |

|

|

| MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| OUTPUT PROBLEMS |

|

|

|

|

|

|

| 115VAC Receptacle not working |

|

| 1. Check for 115VAC at |

|

| 1. If voltage at the receptacle is |

| |||

|

| properly (voltage is below 108VAC). |

|

| receptacle - if low (below |

|

| zero, then check for open cir- |

| |||

|

| Machine has welding output - fan is |

|

| 108VAC), then check input |

|

| cuit breaker (CB1) |

| |||

|

| running. |

|

|

| voltage to machine. |

|

| 2. Check leads #230, #231, and |

| ||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| #232 for loose or broken con- |

| |

|

|

|

|

|

|

|

|

|

| nections. Refer to wiring dia- |

| |

|

|

|

|

|

|

|

|

|

| gram. |

| |

|

|

|

|

|

|

|

|

|

| |||

|

| Machine regularly overheats - ther- |

|

| 1. Welding application may |

|

| 1. Check for proper fan operation. |

| |||

|

| mostat opens, PL1 (yellow light on |

|

| exceed recommended duty |

|

|

|

|

| ||

|

| front panel) glows. The fan runs |

|

| cycle. |

|

| 2. The thermostat may be faulty - |

| |||

|

| but machine has no output and no |

|

|

|

|

| Should be normally closed |

| |||

|

| display. |

|

|

| 2. Dirt and dust may have |

|

|

|

|

| |

|

|

|

|

|

|

| clogged the cooling channels |

|

|

|

|

|

|

|

|

|

|

|

| inside the machine. Blow out |

|

|

|

|

|

|

|

|

|

|

|

| unit with clean, dry |

|

|

|

|

|

|

|

|

|

|

|

| compressed air. |

|

|

|

|

|

|

|

|

|

|

|

| 3. Air intake and exhaust louvers |

|

|

|

|

|

|

|

|

|

|

|

| may be blocked due to |

|

|

|

|

|

|

|

|

|

|

|

| inadequate clearance around |

|

|

|

|

|

|

|

|

|

|

|

| machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| Machine makes a very loud |

|

|

| 1. Inspect output stud insulators |

|

| 1. Diode (D1) may be shorted. |

| ||

|

| buzzing noise in DC Stick Mode, or |

|

| for cracks or signs of over- |

|

| Check and replace if neces- |

| |||

|

| in DC TIG Mode when the arc start |

|

| heating. |

|

| sary. |

| |||

|

| or amptrol is pressed. |

|

|

|

|

|

|

|

|

| |

|

| There is no current draw from |

|

|

|

|

| 2. The SCR bridge may be faulty. |

| |||

|

|

|

|

|

|

| See Static and Active SCR |

| ||||

|

| machine’s output studs. |

|

|

|

|

|

| Tests. |

| ||

|

| (The machine is not externally |

|

|

|

|

|

|

|

| ||

|

| loaded). |

|

|

|

|

|

| 3. Check the polarity switch (S2) |

| ||

|

|

|

|

|

|

|

|

|

| for correct connections. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call