Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

| TROUBLESHOOTING & REPAIR |

| ||

| PROTECTION/SNUBBER BOARD CONTINUITY TEST (continued) | |||

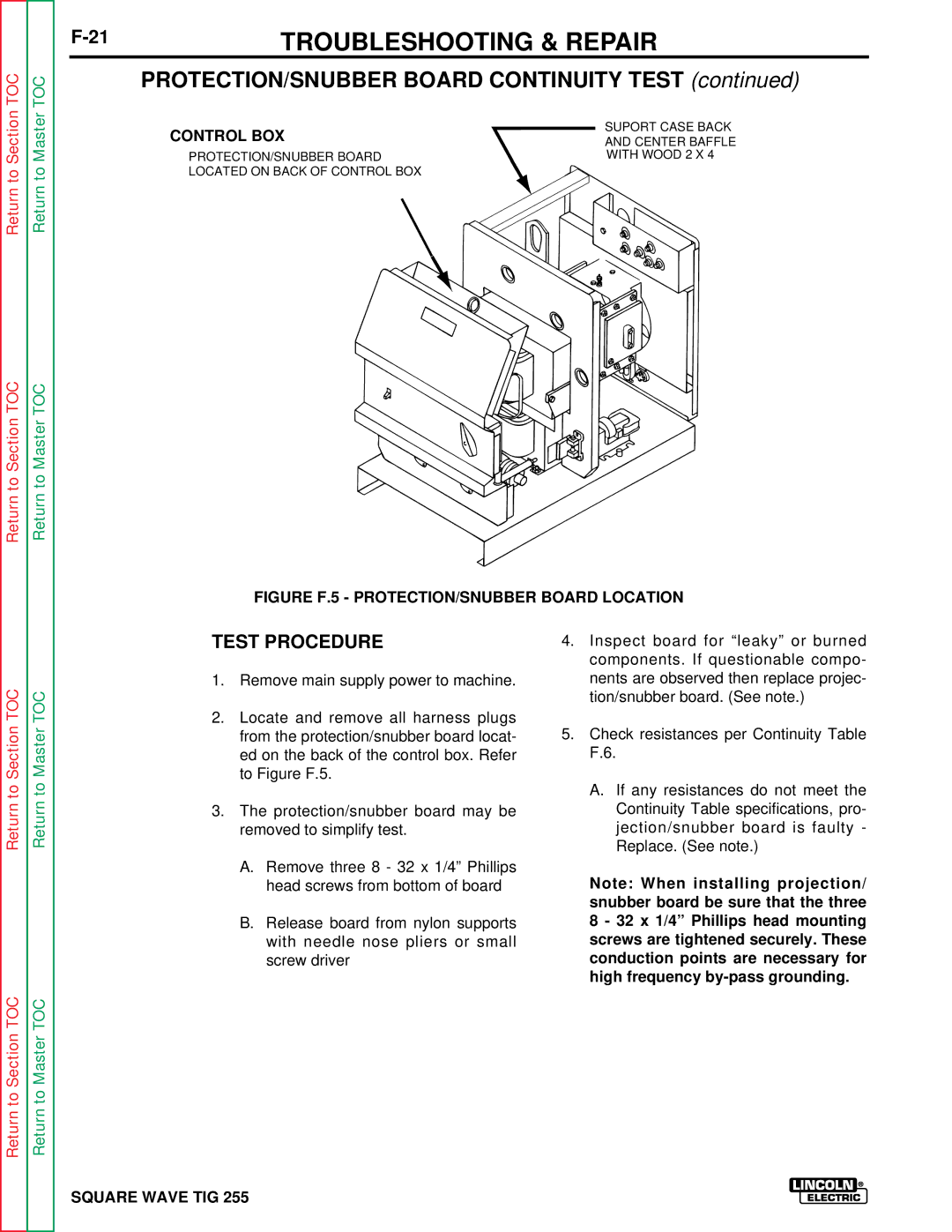

| CONTROL BOX | SUPORT CASE BACK | ||

| AND CENTER BAFFLE | |||

|

|

| ||

| PROTECTION/SNUBBER BOARD | WITH WOOD 2 X 4 | ||

| LOCATED ON BACK OF CONTROL BOX |

|

| |

FIGURE F.5 - PROTECTION/SNUBBER BOARD LOCATION

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TEST PROCEDURE

1.Remove main supply power to machine.

2.Locate and remove all harness plugs from the protection/snubber board locat- ed on the back of the control box. Refer to Figure F.5.

3.The protection/snubber board may be removed to simplify test.

A.Remove three 8 - 32 x 1/4” Phillips head screws from bottom of board

B.Release board from nylon supports with needle nose pliers or small screw driver

4.Inspect board for “leaky” or burned components. If questionable compo- nents are observed then replace projec- tion/snubber board. (See note.)

5.Check resistances per Continuity Table F.6.

A.If any resistances do not meet the Continuity Table specifications, pro- jection/snubber board is faulty - Replace. (See note.)

Note: When installing projection/ snubber board be sure that the three 8 - 32 x 1/4” Phillips head mounting screws are tightened securely. These conduction points are necessary for high frequency