TOC

TOC

INSTALLATION | |

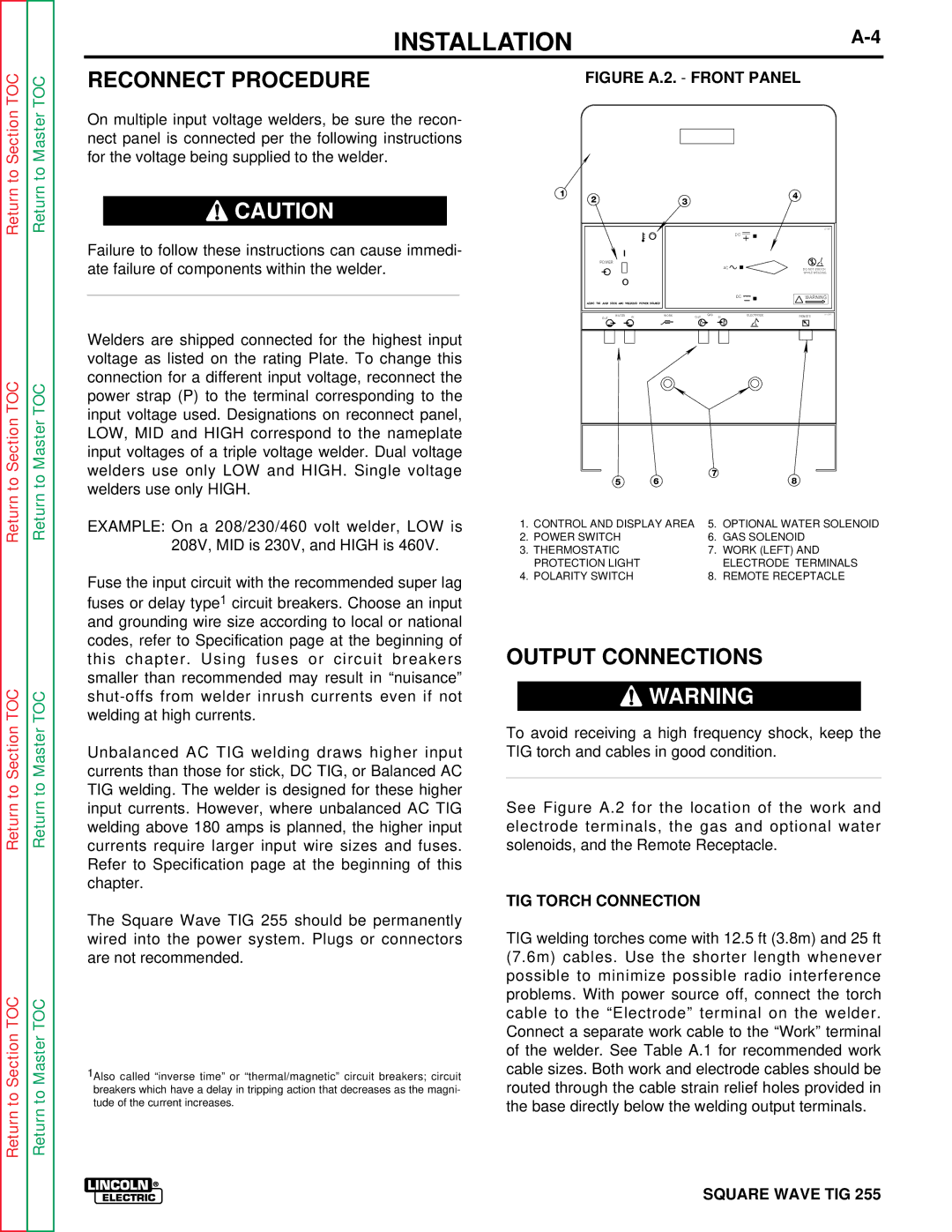

RECONNECT PROCEDURE | FIGURE A.2. - FRONT PANEL |

On multiple input voltage welders, be sure the recon- nect panel is connected per the following instructions for the voltage being supplied to the welder.

![]() CAUTION

CAUTION

Failure to follow these instructions can cause immedi- ate failure of components within the welder.

___________________________________________

Welders are shipped connected for the highest input voltage as listed on the rating Plate. To change this connection for a different input voltage, reconnect the power strap (P) to the terminal corresponding to the input voltage used. Designations on reconnect panel, LOW, MID and HIGH correspond to the nameplate input voltages of a triple voltage welder. Dual voltage welders use only LOW and HIGH. Single voltage welders use only HIGH.

EXAMPLE: On a 208/230/460 volt welder, LOW is 208V, MID is 230V, and HIGH is 460V.

Fuse the input circuit with the recommended super lag fuses or delay type1 circuit breakers. Choose an input and grounding wire size according to local or national codes, refer to Specification page at the beginning of this chapter. Using fuses or circuit breakers smaller than recommended may result in “nuisance”

Unbalanced AC TIG welding draws higher input currents than those for stick, DC TIG, or Balanced AC TIG welding. The welder is designed for these higher input currents. However, where unbalanced AC TIG welding above 180 amps is planned, the higher input currents require larger input wire sizes and fuses. Refer to Specification page at the beginning of this chapter.

The Square Wave TIG 255 should be permanently wired into the power system. Plugs or connectors are not recommended.

1Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit breakers which have a delay in tripping action that decreases as the magni- tude of the current increases.

1 |

|

|

| 3 |

|

| 4 |

2 |

|

|

|

|

|

| |

|

|

|

|

|

| D C |

|

| I |

|

|

|

|

|

|

P O W E R |

|

|

|

|

|

|

|

|

|

|

|

|

| A C | D O N O T S W I T C H |

|

|

|

|

|

|

| W H I L E W E L D I N G |

| O |

|

|

|

|

|

|

|

|

|

|

|

| D C | W A R N I N G |

O U T | W A T E R | I N | W O R K | O U T | G A S | E L E C T R O D E | R E M O T E |

|

|

| I N |

|

| 5 | 6 | 7 | 8 |

|

| |||

1. | CONTROL AND DISPLAY AREA | 5. | OPTIONAL WATER SOLENOID | |

2. | POWER SWITCH |

| 6. | GAS SOLENOID |

3. | THERMOSTATIC |

| 7. | WORK (LEFT) AND |

| PROTECTION LIGHT |

|

| ELECTRODE TERMINALS |

4. | POLARITY SWITCH |

| 8. | REMOTE RECEPTACLE |

OUTPUT CONNECTIONS

![]() WARNING

WARNING

To avoid receiving a high frequency shock, keep the TIG torch and cables in good condition.

___________________________________________

See Figure A.2 for the location of the work and electrode terminals, the gas and optional water solenoids, and the Remote Receptacle.

TIG TORCH CONNECTION

TIG welding torches come with 12.5 ft (3.8m) and 25 ft (7.6m) cables. Use the shorter length whenever possible to minimize possible radio interference problems. With power source off, connect the torch cable to the “Electrode” terminal on the welder. Connect a separate work cable to the “Work” terminal of the welder. See Table A.1 for recommended work cable sizes. Both work and electrode cables should be routed through the cable strain relief holes provided in the base directly below the welding output terminals.