TOC

TOC

INSTALLATION |

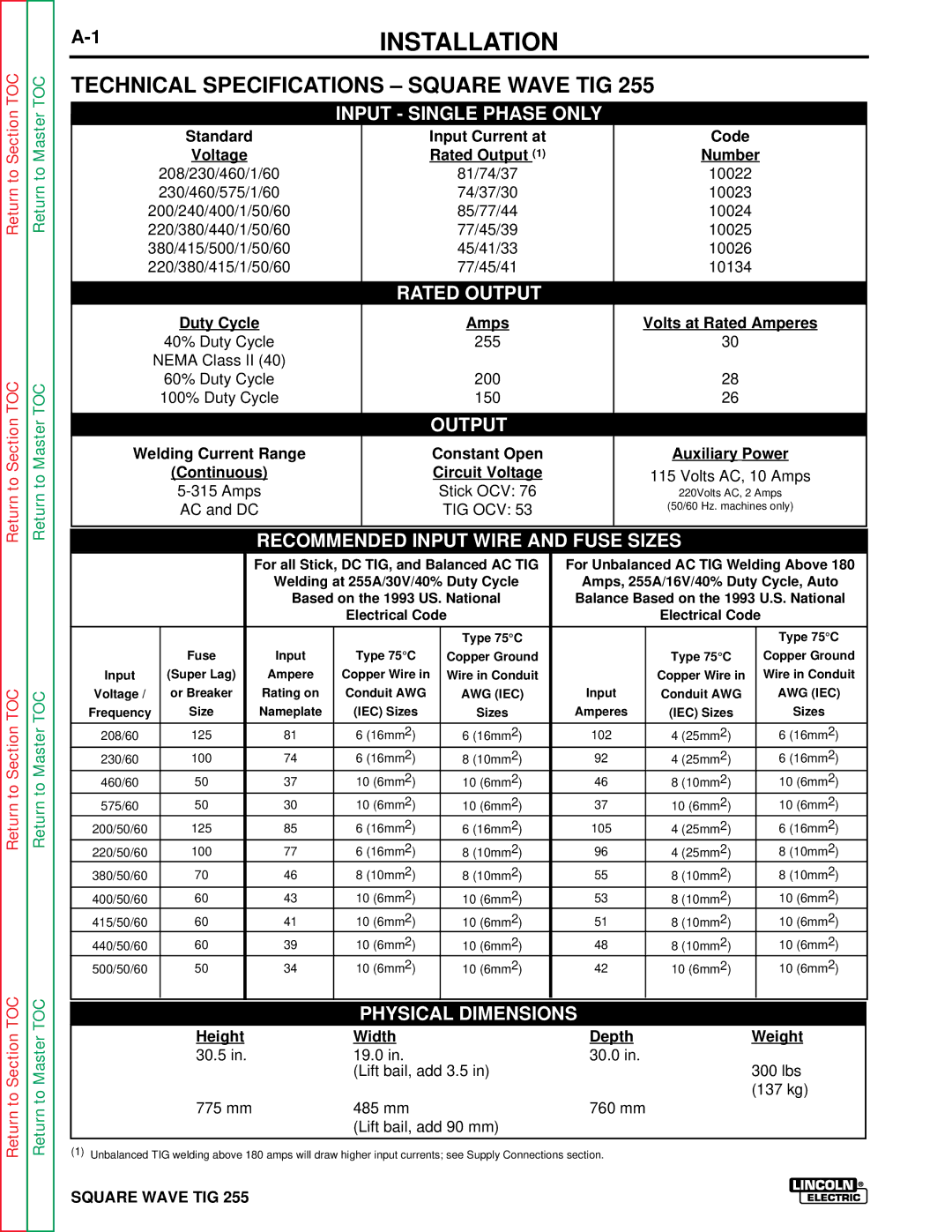

TECHNICAL SPECIFICATIONS – SQUARE WAVE TIG 255

INPUT - SINGLE PHASE ONLY

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

Standard

Voltage

208/230/460/1/60

230/460/575/1/60

200/240/400/1/50/60

220/380/440/1/50/60

380/415/500/1/50/60

220/380/415/1/50/60

Duty Cycle

40% Duty Cycle

NEMA Class II (40)

60% Duty Cycle

100% Duty Cycle

Welding Current Range

(Continuous)

AC and DC

Input Current at

Rated Output (1)

81/74/37

74/37/30

85/77/44

77/45/39

45/41/33

77/45/41

RATED OUTPUT

Amps

255

200

150

OUTPUT

Constant Open

Circuit Voltage

Stick OCV: 76

TIG OCV: 53

Code

Number

10022

10023

10024

10025

10026

10134

Volts at Rated Amperes

30

28

26

Auxiliary Power

115 Volts AC, 10 Amps

220Volts AC, 2 Amps

(50/60 Hz. machines only)

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

RECOMMENDED INPUT WIRE AND FUSE SIZES

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| For all Stick, DC TIG, and Balanced AC TIG |

|

|

| For Unbalanced AC TIG Welding Above 180 |

| |||||||||||

|

|

|

|

|

|

| Welding at 255A/30V/40% Duty Cycle |

|

|

| Amps, 255A/16V/40% Duty Cycle, Auto |

| |||||||||||

|

|

|

|

|

|

| Based on the 1993 US. National |

|

|

| Balance Based on the 1993 U.S. National |

| |||||||||||

|

|

|

|

|

|

|

|

| Electrical Code |

|

|

|

|

|

| Electrical Code |

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Type 75°C |

|

|

|

|

|

|

|

|

|

| Type 75°C |

|

|

|

|

| Fuse |

|

| Input |

| Type 75°C |

| Copper Ground |

|

|

|

|

|

| Type 75°C |

|

|

| Copper Ground |

|

| Input |

|

| (Super Lag) |

|

| Ampere |

| Copper Wire in |

| Wire in Conduit |

|

|

|

|

|

| Copper Wire in |

|

|

| Wire in Conduit |

|

| Voltage / |

|

| or Breaker |

|

| Rating on |

| Conduit AWG |

| AWG (IEC) |

|

|

| Input |

|

| Conduit AWG |

|

|

| AWG (IEC) |

|

| Frequency |

|

| Size |

|

| Nameplate |

| (IEC) Sizes |

| Sizes |

|

|

| Amperes |

|

| (IEC) Sizes |

|

|

| Sizes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 208/60 |

|

| 125 |

|

| 81 |

| 6 (16mm2) |

| 6 (16mm2) |

|

|

| 102 |

|

| 4 (25mm2) |

|

|

| 6 (16mm2) |

|

| 230/60 |

|

| 100 |

|

| 74 |

| 6 (16mm2) |

| 8 (10mm2) |

|

|

| 92 |

|

| 4 (25mm2) |

|

|

| 6 (16mm2) |

|

| 460/60 |

|

| 50 |

|

| 37 |

| 10 (6mm2) |

| 10 (6mm2) |

|

|

| 46 |

|

| 8 (10mm2) |

|

|

| 10 (6mm2) |

|

| 575/60 |

|

| 50 |

|

| 30 |

| 10 (6mm2) |

| 10 (6mm2) |

|

|

| 37 |

|

| 10 (6mm2) |

|

|

| 10 (6mm2) |

|

| 200/50/60 |

|

| 125 |

|

| 85 |

| 6 (16mm2) |

| 6 (16mm2) |

|

|

| 105 |

|

| 4 (25mm2) |

|

|

| 6 (16mm2) |

|

| 220/50/60 |

|

| 100 |

|

| 77 |

| 6 (16mm2) |

| 8 (10mm2) |

|

|

| 96 |

|

| 4 (25mm2) |

|

|

| 8 (10mm2) |

|

| 380/50/60 |

|

| 70 |

|

| 46 |

| 8 (10mm2) |

| 8 (10mm2) |

|

|

| 55 |

|

| 8 (10mm2) |

|

|

| 8 (10mm2) |

|

| 400/50/60 |

|

| 60 |

|

| 43 |

| 10 (6mm2) |

| 10 (6mm2) |

|

|

| 53 |

|

| 8 (10mm2) |

|

|

| 10 (6mm2) |

|

| 415/50/60 |

|

| 60 |

|

| 41 |

| 10 (6mm2) |

| 10 (6mm2) |

|

|

| 51 |

|

| 8 (10mm2) |

|

|

| 10 (6mm2) |

|

| 440/50/60 |

|

| 60 |

|

| 39 |

| 10 (6mm2) |

| 10 (6mm2) |

|

|

| 48 |

|

| 8 (10mm2) |

|

|

| 10 (6mm2) |

|

| 500/50/60 |

|

| 50 |

|

| 34 |

| 10 (6mm2) |

| 10 (6mm2) |

|

|

| 42 |

|

| 10 (6mm2) |

|

|

| 10 (6mm2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PHYSICAL DIMENSIONS

Height | Width | Depth | Weight |

30.5 in. | 19.0 in. | 30.0 in. |

|

| (Lift bail, add 3.5 in) |

| 300 lbs |

|

|

| (137 kg) |

775 mm | 485 mm | 760 mm |

|

(Lift bail, add 90 mm)

(1) Unbalanced TIG welding above 180 amps will draw higher input currents; see Supply Connections section.