Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OPERATION

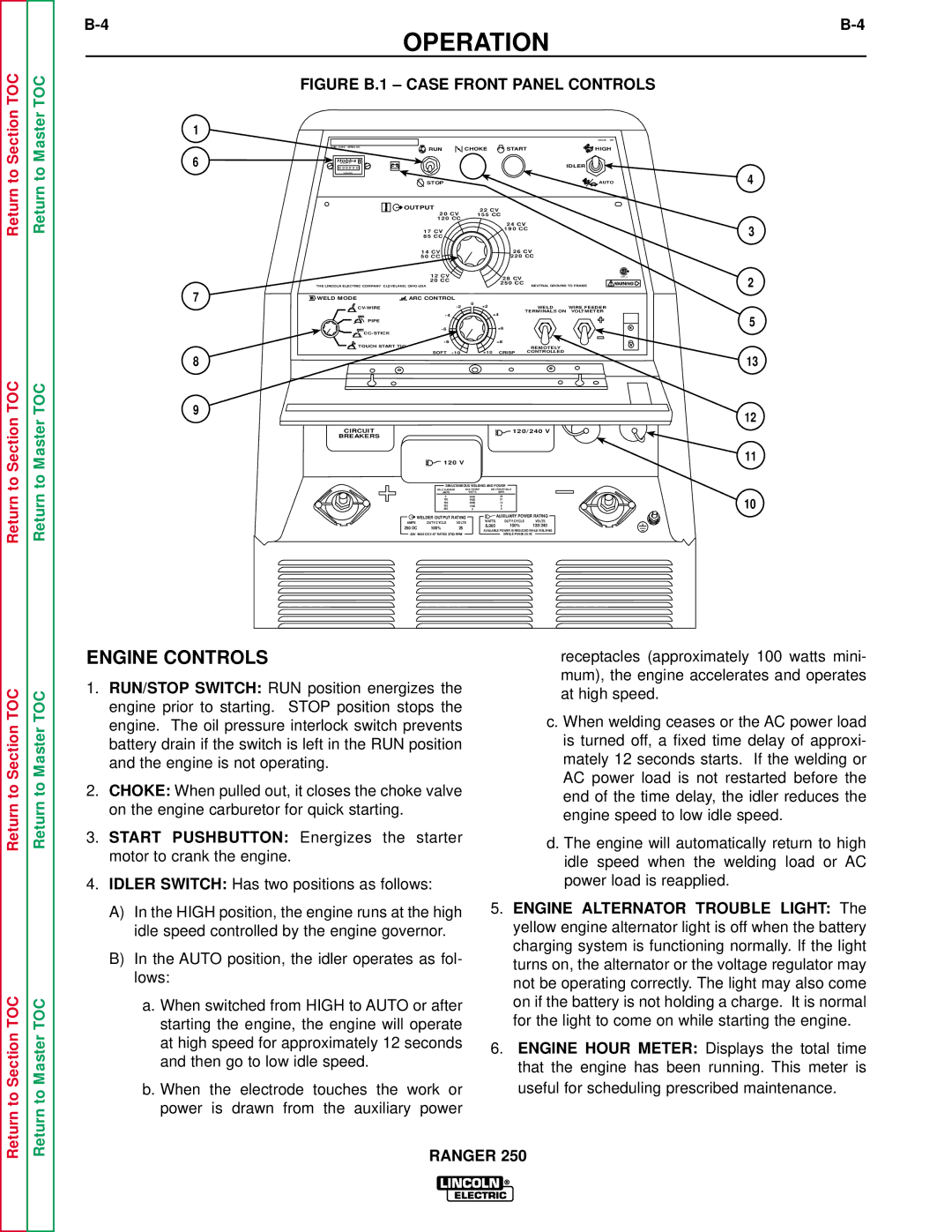

FIGURE B.1 – CASE FRONT PANEL CONTROLS

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| G3668 | VM |

|

| K NO.- CODE - SERIAL NO. |

| RUN |

| CHOKE | START |

| HIGH |

| ||

|

|

|

|

|

| ||||||

6 | Hobbs |

|

|

|

|

|

|

|

|

|

|

0 0 0 0 0 0 |

|

|

|

|

|

|

| IDLER |

|

| |

|

|

| STOP |

|

|

|

|

| AUTO | 4 | |

|

|

|

|

|

|

|

|

|

| ||

|

| OUTPUT |

|

| 22 CV |

|

|

|

| ||

|

|

| 20 CV |

| 155 CC |

|

|

|

| ||

|

|

| 120 CC |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| 24 CV |

|

|

| 3 |

|

|

| 17 CV |

|

|

| 190 CC |

|

| ||

|

|

| 85 CC |

|

|

|

|

|

|

| |

|

|

| 14 CV |

|

|

| 26 CV |

|

|

| |

|

|

| 50 CC |

|

|

| 220 CC |

|

|

| |

|

|

| 12 CV |

|

|

| 28 CV |

|

|

| 2 |

|

|

| 20 CC |

|

|

|

|

|

| ||

|

|

|

|

|

| 250 CC |

|

|

| ||

| THE LINCOLN ELECTRIC COMPANY CLEVELAND, OHIO USA |

|

|

| NEUTRAL GROUND TO FRAME |

| |||||

7 |

|

|

|

|

| ||||||

WELD MODE | ARC CONTROL |

| 0 |

|

|

|

|

| |||

|

|

|

| +2 |

| WELD | WIRE FEEDER |

|

| ||

|

|

|

|

|

|

| TERMINALS ON | VOLTMETER |

|

| |

|

|

|

|

| +4 |

|

|

| 5 | ||

| PIPE |

|

|

|

|

|

|

|

|

| |

|

|

|

|

| +6 |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| +8 |

|

|

|

| |

| TOUCH START TIG |

|

|

|

|

| REMOTELY |

|

|

| |

8 |

|

| SOFT |

| +10 | CRISP | CONTROLLED |

|

| 13 | |

|

|

|

|

|

|

|

|

|

| ||

9 |

|

|

|

|

|

|

|

|

|

| 12 |

|

|

|

|

|

|

|

|

|

|

| |

| CIRCUIT |

|

|

|

|

| 120/240 V |

|

|

| |

| BREAKERS |

|

|

|

|

|

|

|

|

|

|

|

|

| 120 V |

|

|

|

|

|

| 11 | |

|

|

|

|

|

|

|

|

|

| ||

|

|

| SIMULTANEOUS WELDING AND POWER |

|

|

|

| ||||

|

|

| WELD CURRENT | AUX. POWER 240 V. RECEPTACLE |

|

|

|

| |||

|

|

| AMPS |

|

| WATTS | AMPS |

|

|

|

|

|

|

| 0 |

|

| 8000 | 33 |

|

|

| 10 |

|

|

| 100 |

|

| 5000 | 21 |

|

|

| |

|

|

| 250 |

|

| 0 | 0 |

|

|

| |

|

|

| 150 |

|

| 3000 | 13 |

|

|

|

|

|

|

| 200 |

|

| 1500 | 6 |

|

|

|

|

|

| WELDER OUTPUT RATING |

| AUXILIARY POWER RATING |

|

|

| ||||

|

| AMPS | DUTY CYCLE | VOLTS | WATTS | DUTY CYCLE | VOLTS |

|

|

| |

|

| 8,000 | 100% | 120/240 |

|

|

| ||||

|

| 250 DC | 100% | 25 |

|

|

|

| |||

|

|

| AVAILABLE POWER IS REDUCED WHILE WELDING |

|

|

| |||||

|

| 80V MAX OCV AT RATED 3700 RPM |

|

| SINGLE PHASE 60 HZ |

|

|

| |||

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

ENGINE CONTROLS

1.RUN/STOP SWITCH: RUN position energizes the engine prior to starting. STOP position stops the engine. The oil pressure interlock switch prevents battery drain if the switch is left in the RUN position and the engine is not operating.

2.CHOKE: When pulled out, it closes the choke valve on the engine carburetor for quick starting.

3.START PUSHBUTTON: Energizes the starter motor to crank the engine.

4.IDLER SWITCH: Has two positions as follows:

A)In the HIGH position, the engine runs at the high idle speed controlled by the engine governor.

B)In the AUTO position, the idler operates as fol- lows:

a.When switched from HIGH to AUTO or after starting the engine, the engine will operate at high speed for approximately 12 seconds and then go to low idle speed.

b.When the electrode touches the work or power is drawn from the auxiliary power

receptacles (approximately 100 watts mini- mum), the engine accelerates and operates at high speed.

c. When welding ceases or the AC power load is turned off, a fixed time delay of approxi- mately 12 seconds starts. If the welding or AC power load is not restarted before the end of the time delay, the idler reduces the engine speed to low idle speed.

d. The engine will automatically return to high idle speed when the welding load or AC power load is reapplied.

5.ENGINE ALTERNATOR TROUBLE LIGHT: The yellow engine alternator light is off when the battery charging system is functioning normally. If the light turns on, the alternator or the voltage regulator may not be operating correctly. The light may also come on if the battery is not holding a charge. It is normal for the light to come on while starting the engine.

6.ENGINE HOUR METER: Displays the total time that the engine has been running. This meter is useful for scheduling prescribed maintenance.