to Section TOC

to Master TOC

THEORY OF OPERATION

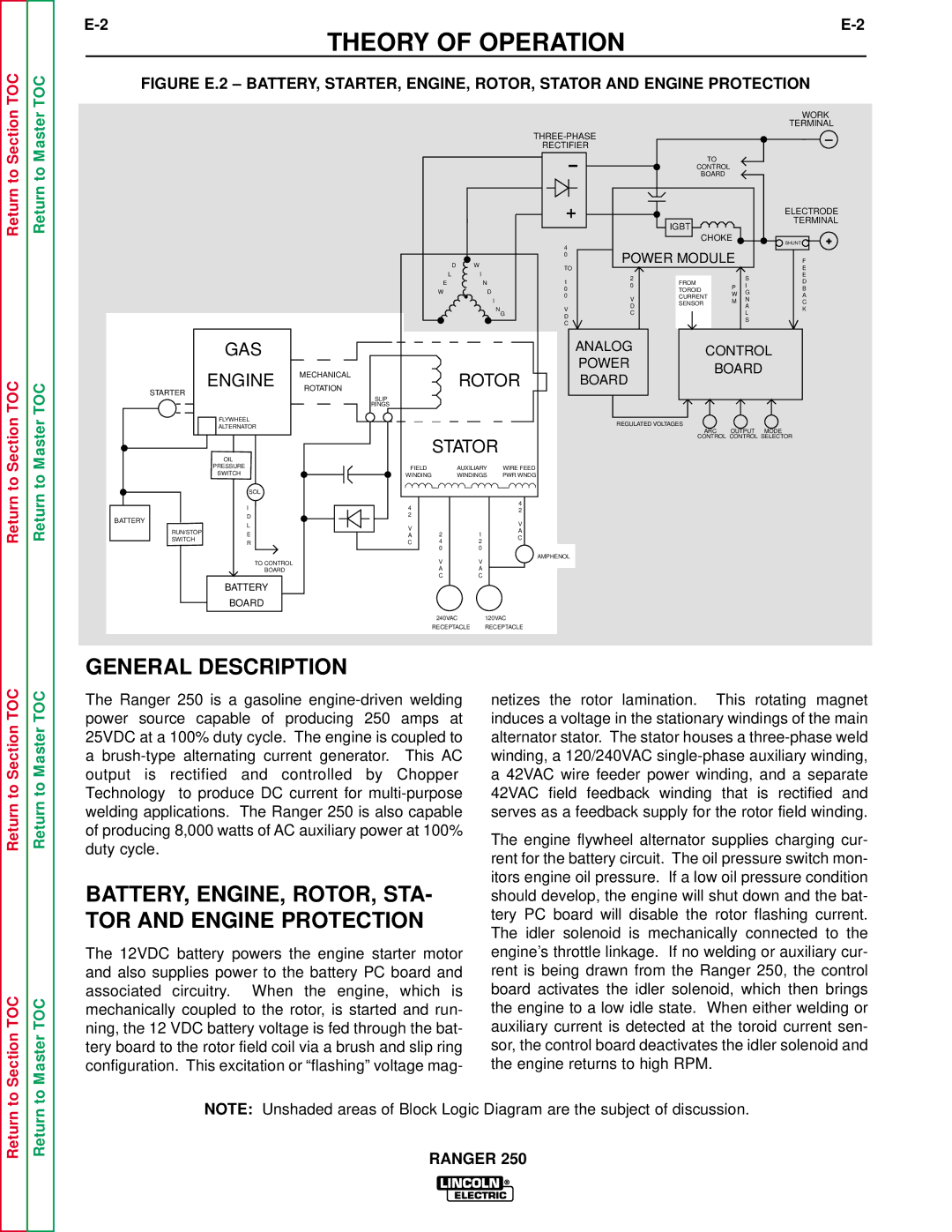

FIGURE E.2 – BATTERY, STARTER, ENGINE, ROTOR, STATOR AND ENGINE PROTECTION

WORK

TERMINAL

| __ | |

RECTIFIER |

|

|

TO

CONTROL

BOARD

D W

L I

EN

WD

I

N

G

+ | ELECTRODE | |

IGBT | TERMINAL | |

|

| |

CHOKE | SHUNT | + |

4 | POWER MODULE |

|

| |||

0 |

| F | ||||

|

| |||||

TO |

|

|

|

| E | |

| 2 |

|

| S | E | |

1 | FROM |

| D | |||

0 | P | I | ||||

0 | TOROID | B | ||||

| G | |||||

0 |

| CURRENT | W | A | ||

V | N | |||||

| SENSOR | M | C | |||

| D | A | ||||

V |

|

| K | |||

C |

|

| L | |||

D |

|

|

| |||

C | S |

|

to Section TOC

to Master TOC

STARTER

GAS

ENGINE MECHANICAL ROTATION

FLYWHEEL

ALTERNATOR

OIL

PRESSURE

SWITCH

|

|

| ANALOG | CONTROL |

|

|

| POWER | |

| ROTOR | BOARD | ||

| BOARD | |||

|

| |||

SLIP |

|

|

|

|

RINGS |

|

|

|

|

|

|

| REGULATED VOLTAGES |

|

|

|

|

| ARC OUTPUT MODE |

| STATOR |

|

| CONTROL CONTROL SELECTOR |

|

|

|

| |

FIELD | AUXILIARY | WIRE FEED |

|

|

WINDING | WINDINGS | PWR WNDG |

|

|

Return

Return

BATTERY

SOL

I

D

L

4 | 4 | |

2 | ||

2 | ||

| ||

V | V | |

|

RUN/STOPE

SWITCH

R

TO CONTROL

BOARD

BATTERY

BOARD

GENERAL DESCRIPTION

A | 2 | 1 | A |

C | 4 | 2 | C |

| |||

| 0 | 0 | AMPHENOL |

| V | V | |

|

|

AA

CC

240VAC 120VAC

RECEPTACLE RECEPTACLE

Return to Section TOC

to Section TOC

The Ranger 250 is a gasoline

BATTERY, ENGINE, ROTOR, STA- TOR AND ENGINE PROTECTION

The 12VDC battery powers the engine starter motor and also supplies power to the battery PC board and associated circuitry. When the engine, which is mechanically coupled to the rotor, is started and run- ning, the 12 VDC battery voltage is fed through the bat- tery board to the rotor field coil via a brush and slip ring configuration. This excitation or “flashing” voltage mag-

netizes the rotor lamination. This rotating magnet induces a voltage in the stationary windings of the main alternator stator. The stator houses a

The engine flywheel alternator supplies charging cur- rent for the battery circuit. The oil pressure switch mon- itors engine oil pressure. If a low oil pressure condition should develop, the engine will shut down and the bat- tery PC board will disable the rotor flashing current. The idler solenoid is mechanically connected to the engine’s throttle linkage. If no welding or auxiliary cur- rent is being drawn from the Ranger 250, the control board activates the idler solenoid, which then brings the engine to a low idle state. When either welding or auxiliary current is detected at the toroid current sen- sor, the control board deactivates the idler solenoid and the engine returns to high RPM.