OPERATION

Return to Section TOC

Return to Section TOC

WELDER OPERATION

GENERAL INFORMATION

WARNING

•Do not touch electrically live parts or elec- trodes with your skin or wet clothing.

•Do not breathe welding fumes or gases.

•Use ventilation or exhaust to remove weld- ing from the breathing area.

•Keep flammable material away.

•Wear eye, ear, and body protection.

The Ranger 250 can deliver from 40 to 250 amps of constant current for DC stick welding or from 20 to 250 amps of constant voltage current for DC semiautomat- ic wire feed welding. DC TIG welding is possible across the entire range from 20 to maximum rated out- put. Output can be adjusted by setting the OUTPUT control dial and the ARC control dial on the output con- trol panel to the settings that are best for your selected welding process.

NOTE: An unstable or unsatisfactory welding arc can result if welding cables are too long or are coiled on the machine when welding. See Table A.1 in the Installation section. Straighten out coiled cables before welding.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

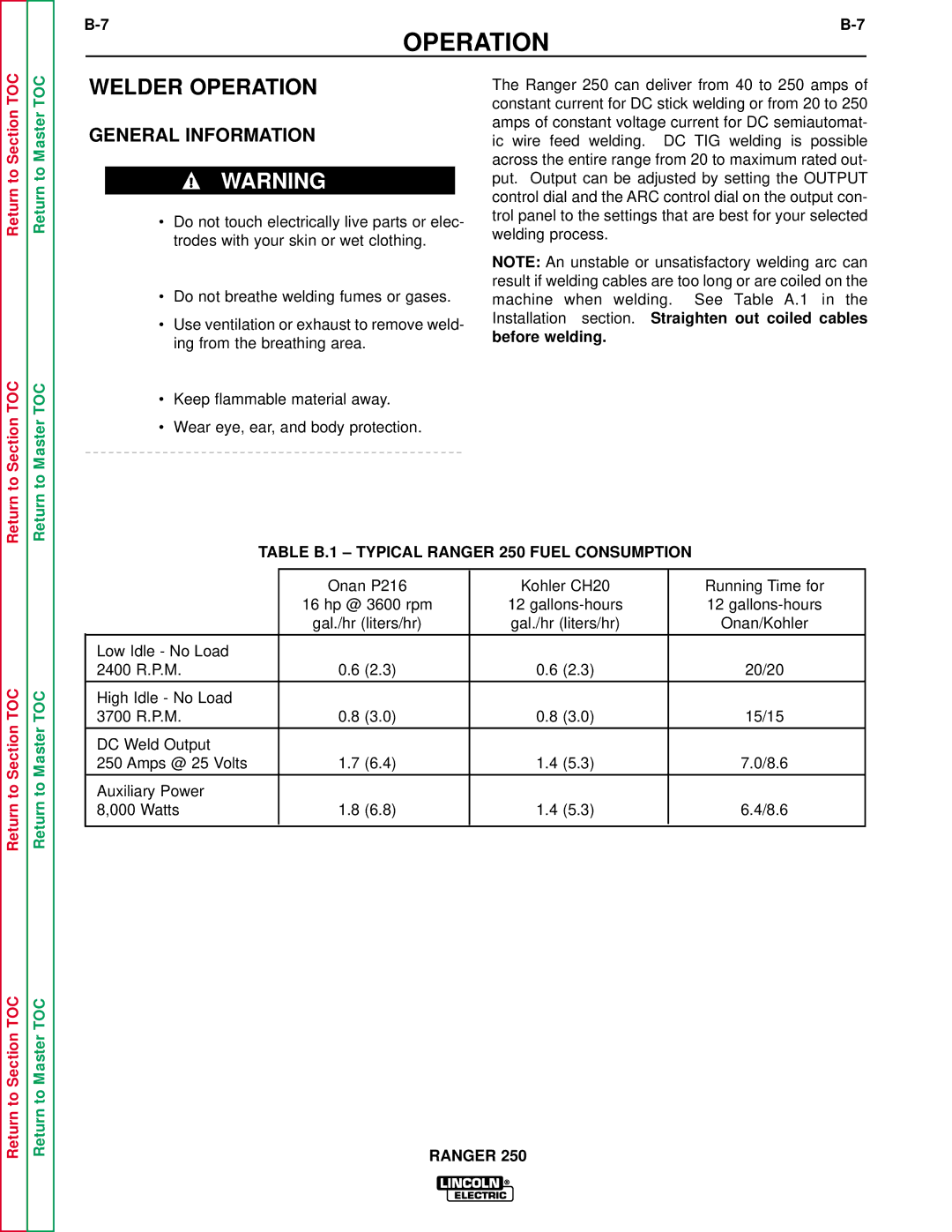

| TABLE B.1 – TYPICAL RANGER 250 FUEL CONSUMPTION |

| |||

|

|

|

|

|

| |

|

|

| Onan P216 | Kohler CH20 |

| Running Time for |

|

|

| 16 hp @ 3600 rpm | 12 |

| 12 |

|

|

| gal./hr (liters/hr) | gal./hr (liters/hr) |

| Onan/Kohler |

|

|

|

|

|

|

|

| Low Idle - No Load |

|

|

|

|

|

| 2400 R.P.M. |

| 0.6 (2.3) | 0.6 (2.3) |

| 20/20 |

|

|

|

|

|

|

|

| High Idle - No Load |

|

|

|

|

|

| 3700 R.P.M. |

| 0.8 (3.0) | 0.8 (3.0) |

| 15/15 |

|

|

|

|

|

|

|

| DC Weld Output |

|

|

|

|

|

| 250 Amps @ 25 Volts |

| 1.7 (6.4) | 1.4 (5.3) |

| 7.0/8.6 |

|

|

|

|

|

|

|

| Auxiliary Power |

|

|

|

|

|

| 8,000 Watts |

| 1.8 (6.8) | 1.4 (5.3) |

| 6.4/8.6 |

|

|

|

|

|

|

|