OPERATION

Return to Section TOC

BREAK-IN PERIOD

Any engine will use a small amount of oil during its

Check the oil frequently during

WELDING OPERATION

GENERAL INFORMATION

WARNING

Do not touch electrically live parts or elec- trodes with your skin or wet clothing.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

LOW OIL SENSING

This engine has a

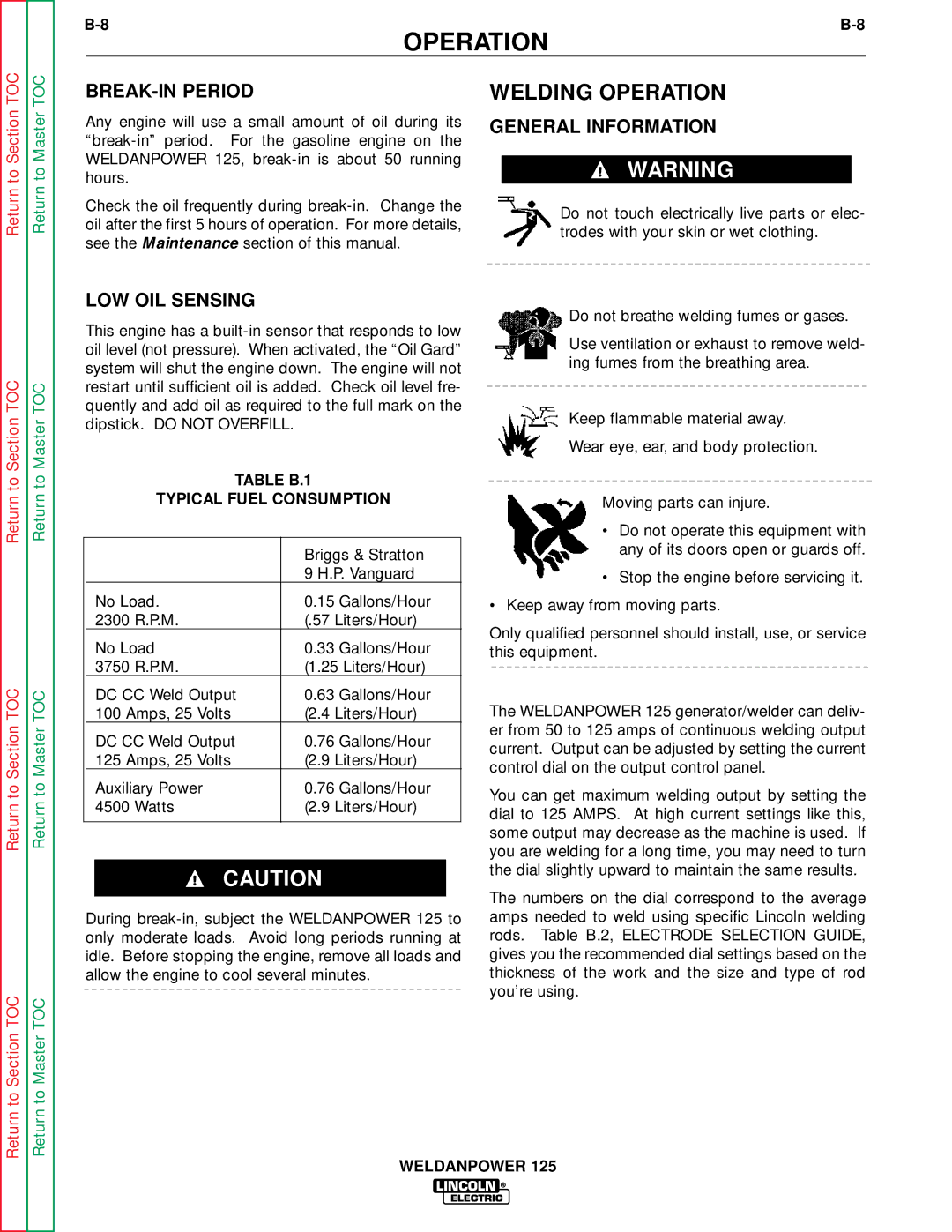

TABLE B.1

TYPICAL FUEL CONSUMPTION

| Briggs & Stratton |

| 9 H.P. Vanguard |

No Load. | 0.15 Gallons/Hour |

2300 R.P.M. | (.57 Liters/Hour) |

No Load | 0.33 Gallons/Hour |

3750 R.P.M. | (1.25 Liters/Hour) |

DC CC Weld Output | 0.63 Gallons/Hour |

100 Amps, 25 Volts | (2.4 Liters/Hour) |

DC CC Weld Output | 0.76 Gallons/Hour |

125 Amps, 25 Volts | (2.9 Liters/Hour) |

Auxiliary Power | 0.76 Gallons/Hour |

4500 Watts | (2.9 Liters/Hour) |

|

|

CAUTION

During

Do not breathe welding fumes or gases.

Use ventilation or exhaust to remove weld- ing fumes from the breathing area.

Keep flammable material away.

Wear eye, ear, and body protection.

Moving parts can injure.

•Do not operate this equipment with any of its doors open or guards off.

•Stop the engine before servicing it.

•Keep away from moving parts.

Only qualified personnel should install, use, or service this equipment.

The WELDANPOWER 125 generator/welder can deliv- er from 50 to 125 amps of continuous welding output current. Output can be adjusted by setting the current control dial on the output control panel.

You can get maximum welding output by setting the dial to 125 AMPS. At high current settings like this, some output may decrease as the machine is used. If you are welding for a long time, you may need to turn the dial slightly upward to maintain the same results.

The numbers on the dial correspond to the average amps needed to weld using specific Lincoln welding rods. Table B.2, ELECTRODE SELECTION GUIDE, gives you the recommended dial settings based on the thickness of the work and the size and type of rod you’re using.

WELDANPOWER 125