Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

TROUBLESHOOTING & REPAIR

ENGINE THROTTLE ADJUSTMENT TEST (continued)

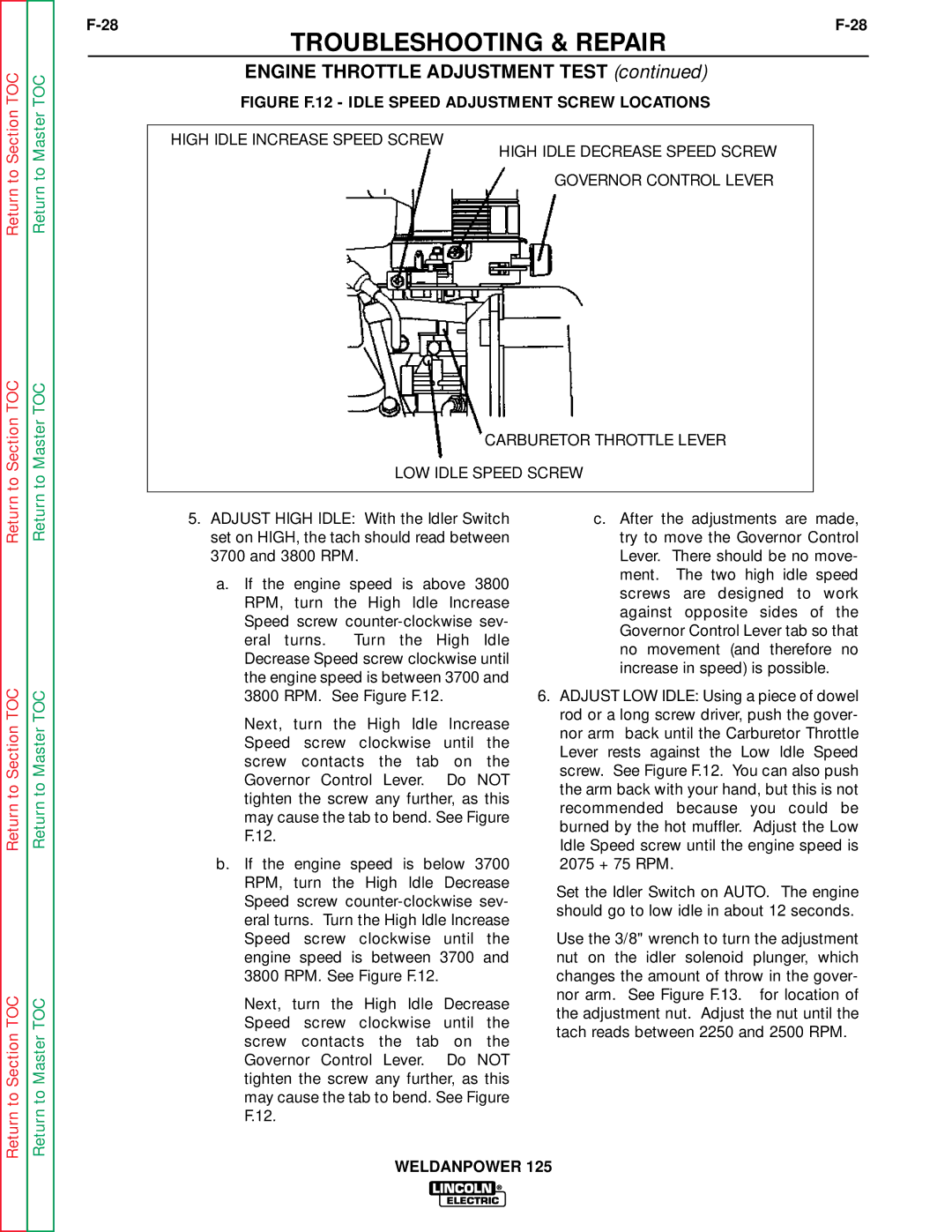

FIGURE F.12 - IDLE SPEED ADJUSTMENT SCREW LOCATIONS

HIGH IDLE INCREASE SPEED SCREW

HIGH IDLE DECREASE SPEED SCREW

GOVERNOR CONTROL LEVER

CARBURETOR THROTTLE LEVER

LOW IDLE SPEED SCREW

Return

Return to Section TOC

Return to Section TOC

Return

Return to Master TOC

Return to Master TOC

5.ADJUST HIGH IDLE: With the Idler Switch set on HIGH, the tach should read between 3700 and 3800 RPM.

a.If the engine speed is above 3800 RPM, turn the High Idle Increase Speed screw

Next, turn the High Idle Increase Speed screw clockwise until the screw contacts the tab on the Governor Control Lever. Do NOT tighten the screw any further, as this may cause the tab to bend. See Figure F.12.

b.If the engine speed is below 3700 RPM, turn the High Idle Decrease Speed screw

Next, turn the High Idle Decrease Speed screw clockwise until the screw contacts the tab on the Governor Control Lever. Do NOT tighten the screw any further, as this may cause the tab to bend. See Figure F.12.

c.After the adjustments are made, try to move the Governor Control Lever. There should be no move- ment. The two high idle speed screws are designed to work against opposite sides of the Governor Control Lever tab so that no movement (and therefore no increase in speed) is possible.

6.ADJUST LOW IDLE: Using a piece of dowel rod or a long screw driver, push the gover- nor arm back until the Carburetor Throttle Lever rests against the Low Idle Speed screw. See Figure F.12. You can also push the arm back with your hand, but this is not recommended because you could be burned by the hot muffler. Adjust the Low Idle Speed screw until the engine speed is 2075 + 75 RPM.

Set the Idler Switch on AUTO. The engine should go to low idle in about 12 seconds.

Use the 3/8" wrench to turn the adjustment nut on the idler solenoid plunger, which changes the amount of throw in the gover- nor arm. See Figure F.13. for location of the adjustment nut. Adjust the nut until the tach reads between 2250 and 2500 RPM.

WELDANPOWER 125