Return to Section TOC

Return to Master TOC

OPERATION

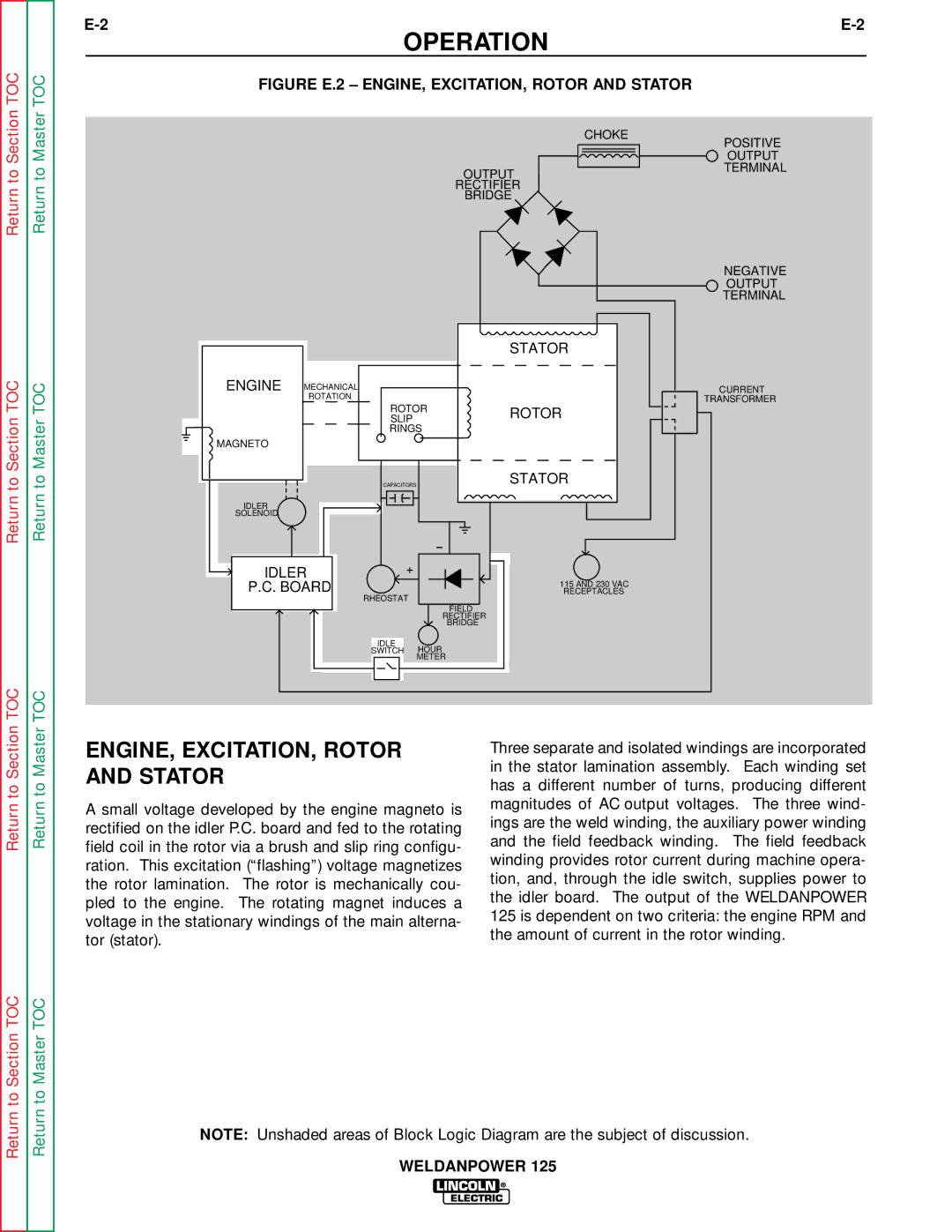

FIGURE E.2 – ENGINE, EXCITATION, ROTOR AND STATOR

| CHOKE |

| POSITIVE |

| OUTPUT |

OUTPUT | TERMINAL |

| |

RECTIFIER |

|

BRIDGE |

|

Return to Section TOC

Return to Master TOC

|

|

|

| STATOR |

ENGINE | MECHANICAL |

|

|

|

| ROTATION |

|

|

|

|

| ROTOR | ROTOR | |

|

| SLIP |

| |

|

| RINGS |

| |

MAGNETO |

|

|

|

|

|

| CAPACITORS |

| STATOR |

IDLER |

|

|

|

|

SOLENOID |

|

|

|

|

IDLER | + |

|

| |

P.C. BOARD |

|

| 115 AND 230 VAC | |

RHEOSTAT |

| RECEPTACLES | ||

|

|

|

| |

|

|

| FIELD |

|

|

|

| RECTIFIER |

|

|

|

| BRIDGE |

|

|

| IDLE | HOUR |

|

|

| SWITCH |

| |

|

|

| METER |

|

NEGATIVE OUTPUT TERMINAL

CURRENT

TRANSFORMER

Return to Section TOC

Return to Master TOC

ENGINE, EXCITATION, ROTOR AND STATOR

A small voltage developed by the engine magneto is rectified on the idler P.C. board and fed to the rotating field coil in the rotor via a brush and slip ring configu- ration. This excitation (“flashing”) voltage magnetizes the rotor lamination. The rotor is mechanically cou- pled to the engine. The rotating magnet induces a voltage in the stationary windings of the main alterna- tor (stator).

Three separate and isolated windings are incorporated in the stator lamination assembly. Each winding set has a different number of turns, producing different magnitudes of AC output voltages. The three wind- ings are the weld winding, the auxiliary power winding and the field feedback winding. The field feedback winding provides rotor current during machine opera- tion, and, through the idle switch, supplies power to the idler board. The output of the WELDANPOWER 125 is dependent on two criteria: the engine RPM and the amount of current in the rotor winding.

Return to Section TOC

Return to Master TOC

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

WELDANPOWER 125