Section 7 | Refrigeration System |

|

|

Refrigerant Recovery/Evacuation and Recharging

REFRIGERANT RECOVERY/EVACUATION

Normal Self-Contained Model Procedures

Do not purge refrigerant to the atmosphere. Capture refrigerant using recovery equipment. Follow the manufacturer’s recommendations.

Important

1.Place the toggle switch in the OFF position and disconnect all power.

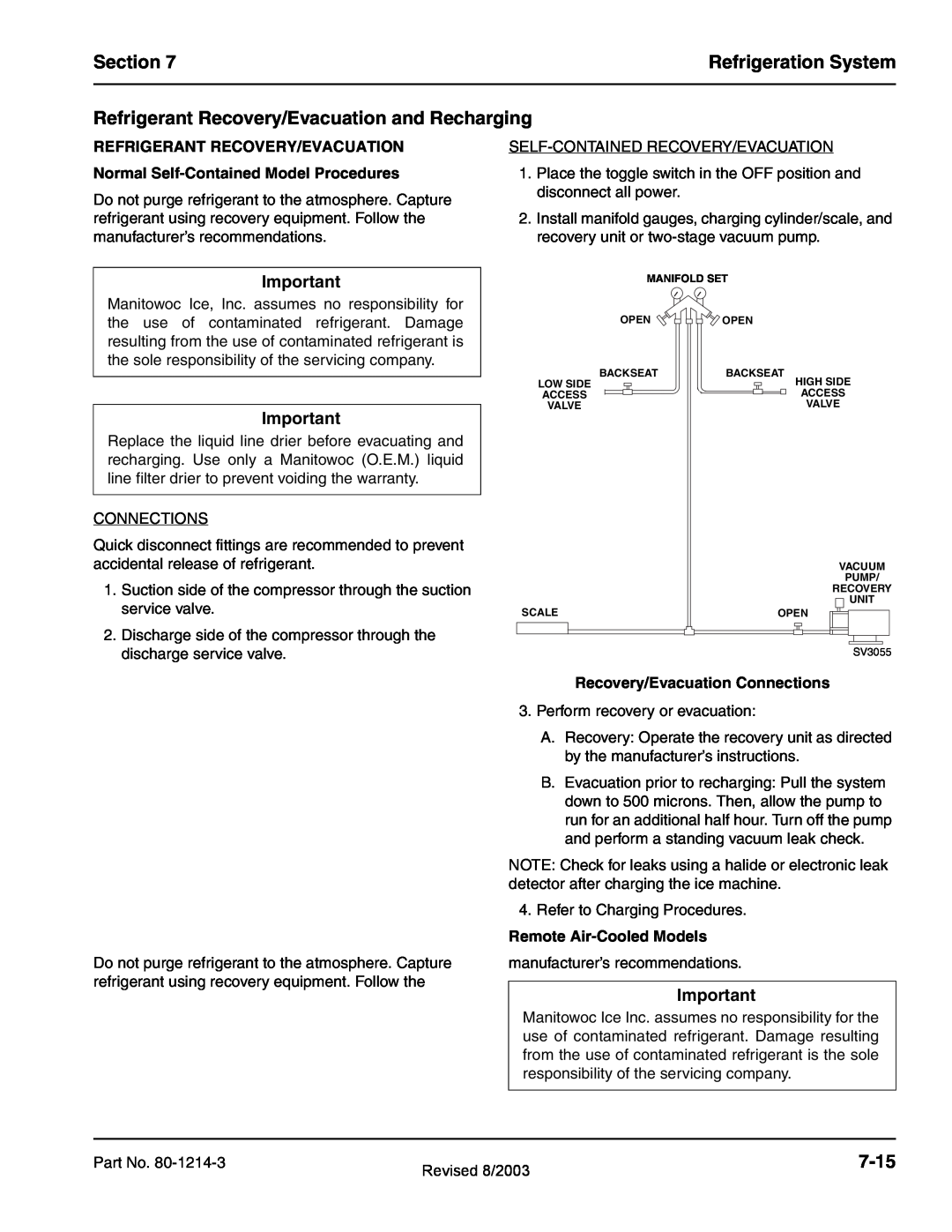

2.Install manifold gauges, charging cylinder/scale, and recovery unit or

MANIFOLD SET

Manitowoc Ice, Inc. assumes no responsibility for the use of contaminated refrigerant. Damage resulting from the use of contaminated refrigerant is the sole responsibility of the servicing company.

Important

Replace the liquid line drier before evacuating and recharging. Use only a Manitowoc (O.E.M.) liquid line filter drier to prevent voiding the warranty.

CONNECTIONS

Quick disconnect fittings are recommended to prevent accidental release of refrigerant.

1.Suction side of the compressor through the suction service valve.

2.Discharge side of the compressor through the discharge service valve.

OPEN

BACKSEAT

LOW SIDE ACCESS VALVE

SCALE

OPEN

BACKSEAT

HIGH SIDE ACCESS

VALVE

VACUUM

PUMP/

RECOVERY

UNIT

OPEN

SV3055

Do not purge refrigerant to the atmosphere. Capture refrigerant using recovery equipment. Follow the

Recovery/Evacuation Connections

3.Perform recovery or evacuation:

A.Recovery: Operate the recovery unit as directed by the manufacturer’s instructions.

B.Evacuation prior to recharging: Pull the system down to 500 microns. Then, allow the pump to run for an additional half hour. Turn off the pump and perform a standing vacuum leak check.

NOTE: Check for leaks using a halide or electronic leak detector after charging the ice machine.

4. Refer to Charging Procedures.

Remote Air-Cooled Models

manufacturer’s recommendations.

Important

Manitowoc Ice Inc. assumes no responsibility for the use of contaminated refrigerant. Damage resulting from the use of contaminated refrigerant is the sole responsibility of the servicing company.

Part No. | Revised 8/2003 |

|

|

|