Section 3 | Ice Machine Operation |

|

|

Operational Checks

GENERAL

Manitowoc ice machines are

To ensure proper operation, always follow the Operational Checks:

•when starting the ice machine for the first time

•after a prolonged out of service period

•after cleaning and sanitizing

NOTE: Routine adjustments and maintenance procedures outlined in this manual are not covered by the warranty.

WATER LEVEL CHECK

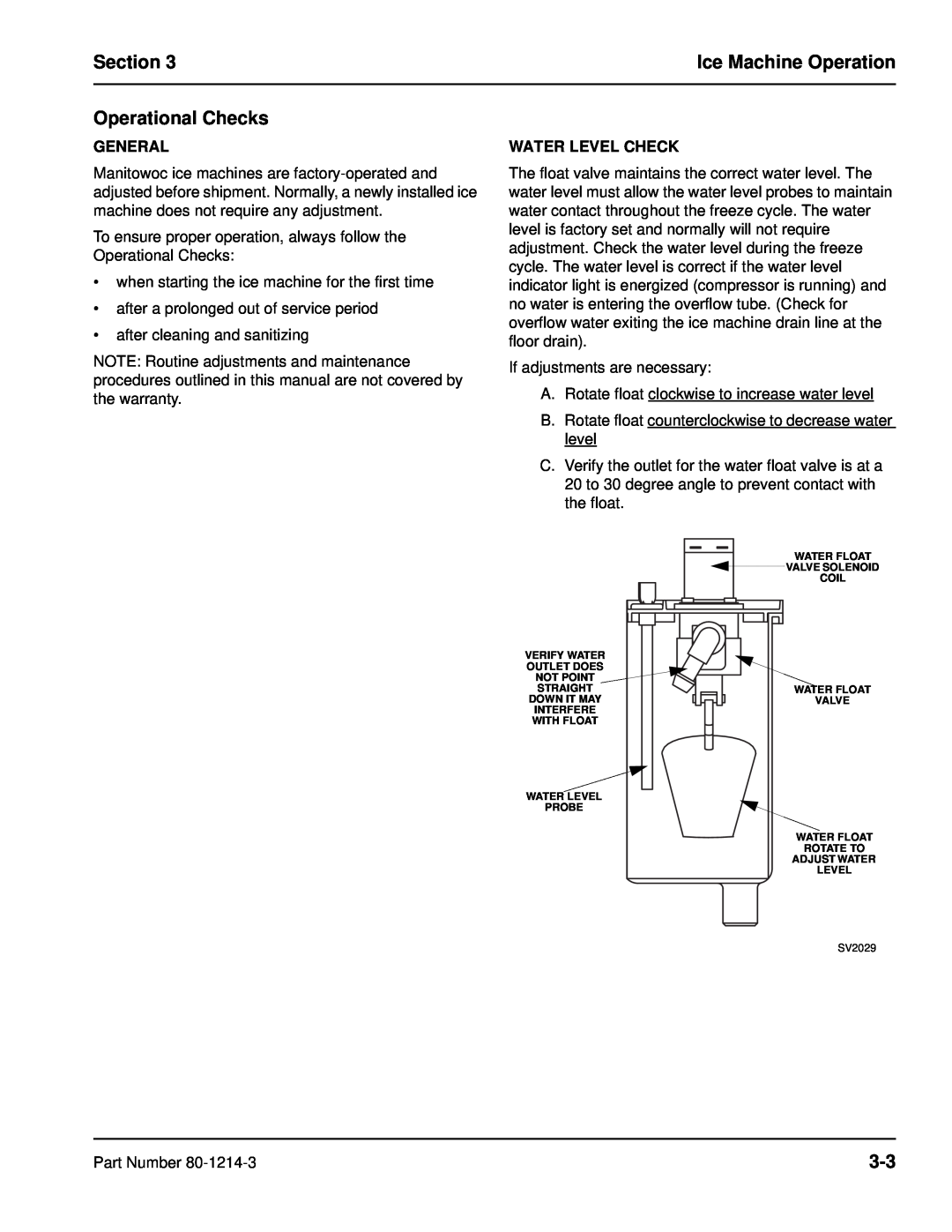

The float valve maintains the correct water level. The water level must allow the water level probes to maintain water contact throughout the freeze cycle. The water level is factory set and normally will not require adjustment. Check the water level during the freeze cycle. The water level is correct if the water level indicator light is energized (compressor is running) and no water is entering the overflow tube. (Check for overflow water exiting the ice machine drain line at the floor drain).

If adjustments are necessary:

A.Rotate float clockwise to increase water level

B.Rotate float counterclockwise to decrease water level

C.Verify the outlet for the water float valve is at a 20 to 30 degree angle to prevent contact with the float.

WATER FLOAT

![]() VALVE SOLENOID

VALVE SOLENOID

COIL

VERIFY WATER |

|

OUTLET DOES |

|

NOT POINT |

|

STRAIGHT | WATER FLOAT |

DOWN IT MAY | VALVE |

INTERFERE |

|

WITH FLOAT |

|

WATER LEVEL

PROBE

WATER FLOAT

ROTATE TO

ADJUST WATER

LEVEL

SV2029

Part Number |