Section 6 | Electrical System |

|

|

HIGH PRESSURE CONTROL (HPCO)

Function

The high pressure control stops the ice machine if subjected to excessive

The HPCO control is normally closed, and opens on a rise in discharge pressure.

Specifications

(must be below 300 psig to reset).

Check Procedure

1.Set ICE/OFF/CLEAN switch to OFF.

2.Disconnect main power supply to the ice machine.

3.Connect manifold gauges to access valves.

4.Hook voltmeter in parallel across the HPCO, leaving wires attached.

5.Reconnect main power supply to the ice machine.

6.Set ICE/OFF/CLEAN switch to ICE and block condenser with cardboard or similar material.

7.No air flowing through the condenser will cause the HPCO control to open because of excessive pressure. Watch the pressure gauge and record the

!Warning

If discharge pressure exceeds 460 psig and the HPCO control does not cut out, set ICE/OFF/CLEAN switch to OFF to stop ice machine operation.

Replace the HPCO control if it:

•Will not reset (below 300 psig).

•Does not open at the specified

LOW PRESSURE

Function

Energizes and

The LPCO control is closed at pressures above setpoint and opens at pressures below setpoint.

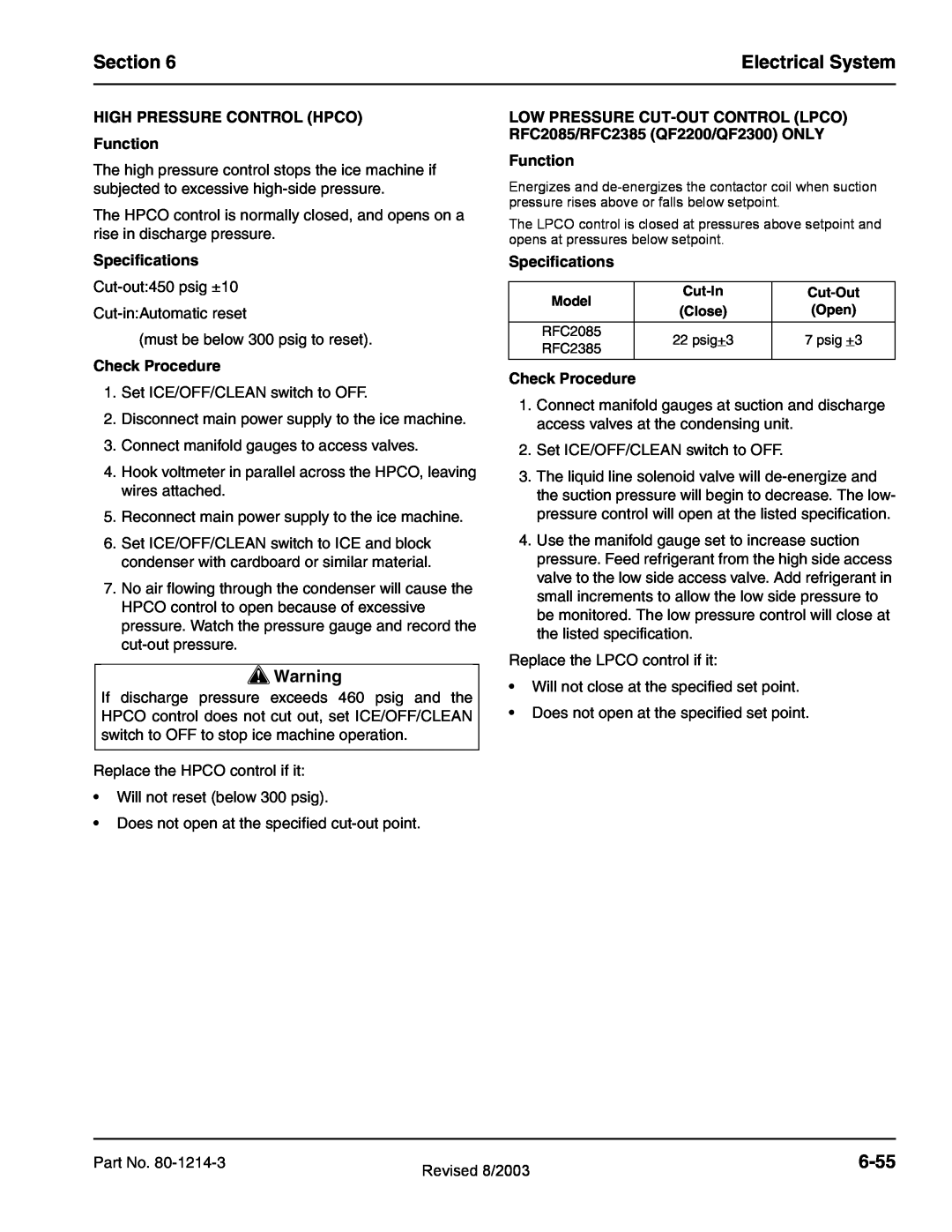

Specifications

Model |

| ||

| (Close) | (Open) | |

|

| ||

|

|

|

|

RFC2085 |

| 22 psig+3 | 7 psig +3 |

RFC2385 |

| ||

|

|

| |

|

|

|

|

Check Procedure |

|

| |

1.Connect manifold gauges at suction and discharge access valves at the condensing unit.

2.Set ICE/OFF/CLEAN switch to OFF.

3.The liquid line solenoid valve will

4.Use the manifold gauge set to increase suction pressure. Feed refrigerant from the high side access valve to the low side access valve. Add refrigerant in small increments to allow the low side pressure to be monitored. The low pressure control will close at the listed specification.

Replace the LPCO control if it:

•Will not close at the specified set point.

•Does not open at the specified set point.

Part No. | Revised 8/2003 |

|

|

|