Troubleshooting | Section 5 |

|

|

Temperature is Too High or Low

QF2200 Only

The temperature sensor (thermistor) is mounted on the liquid line. The temperature sensor provides input to the control board. The control board monitors the temperature anytime the liquid line solenoid valve is energized.

If the thermistor detects 123°F or higher for 15 continuous seconds:

1.The ice machine will

2.The control board “Disch Temp” light will continue to flash twice then pause, to indicate the ice machine has shut off on high temperature.

3.The ice machine will remain off until the toggle switch is moved from ICE to OFF, and back to ICE.

or

Line voltage is interrupted and restored.

If the thermistor detects 30°F or less for 3 continuous minutes:

1.The control board ignores the low temperature limit for the first 30 minutes of compressor run time.

2.The ice machine will

3.After the

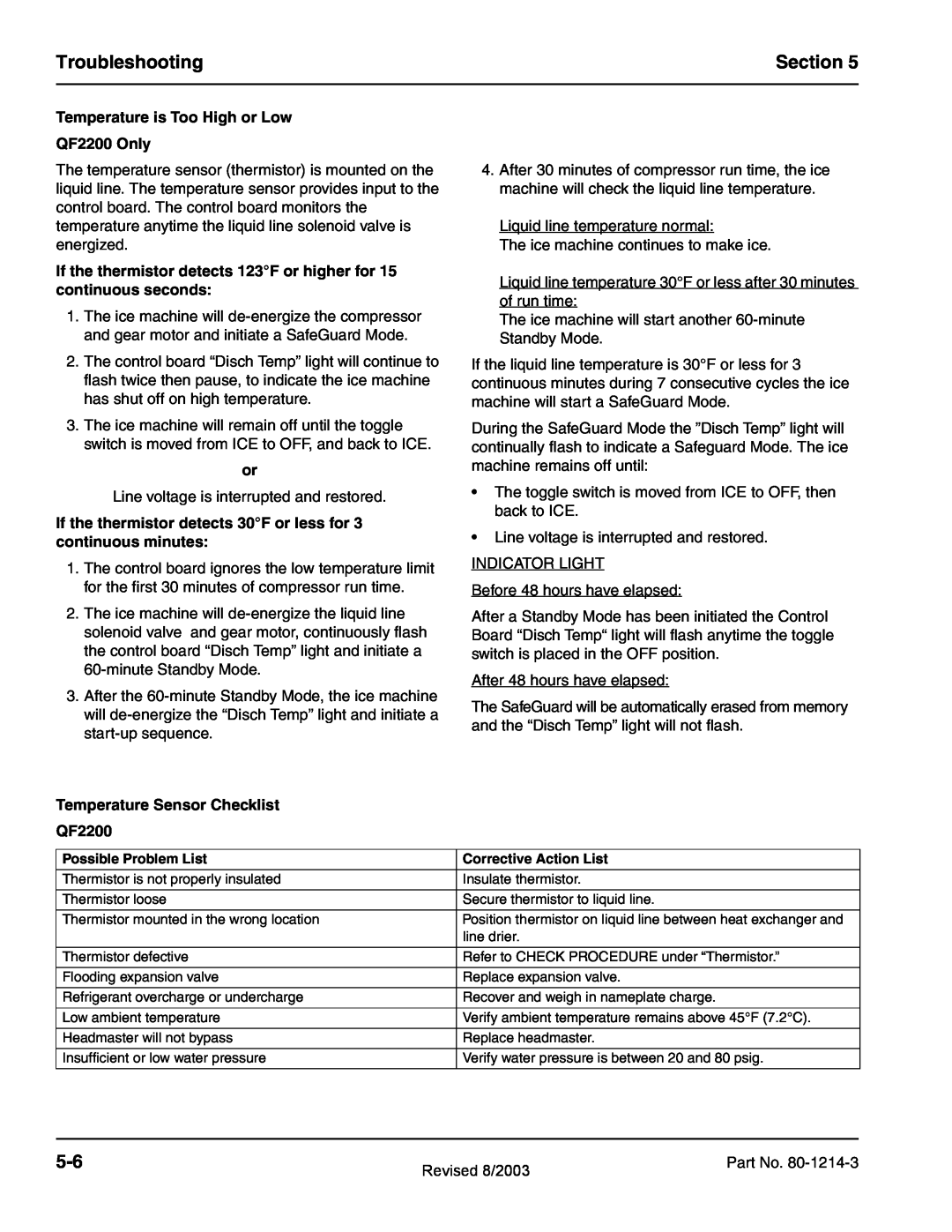

Temperature Sensor Checklist

QF2200

4.After 30 minutes of compressor run time, the ice machine will check the liquid line temperature.

Liquid line temperature normal:

The ice machine continues to make ice.

Liquid line temperature 30°F or less after 30 minutes of run time:

The ice machine will start another

If the liquid line temperature is 30°F or less for 3 continuous minutes during 7 consecutive cycles the ice machine will start a SafeGuard Mode.

During the SafeGuard Mode the ”Disch Temp” light will continually flash to indicate a Safeguard Mode. The ice machine remains off until:

•The toggle switch is moved from ICE to OFF, then back to ICE.

•Line voltage is interrupted and restored.

INDICATOR LIGHT

Before 48 hours have elapsed:

After a Standby Mode has been initiated the Control Board “Disch Temp“ light will flash anytime the toggle switch is placed in the OFF position.

After 48 hours have elapsed:

The SafeGuard will be automatically erased from memory and the “Disch Temp” light will not flash.

Possible Problem List | Corrective Action List |

|

|

Thermistor is not properly insulated | Insulate thermistor. |

|

|

Thermistor loose | Secure thermistor to liquid line. |

|

|

Thermistor mounted in the wrong location | Position thermistor on liquid line between heat exchanger and |

| line drier. |

|

|

Thermistor defective | Refer to CHECK PROCEDURE under “Thermistor.” |

|

|

Flooding expansion valve | Replace expansion valve. |

|

|

Refrigerant overcharge or undercharge | Recover and weigh in nameplate charge. |

|

|

Low ambient temperature | Verify ambient temperature remains above 45°F (7.2°C). |

|

|

Headmaster will not bypass | Replace headmaster. |

|

|

Insufficient or low water pressure | Verify water pressure is between 20 and 80 psig. |

|

|

Revised 8/2003 | Part No. | |

|

|