Installation Instructions | Section 2 |

|

|

Verify

Torque Value’s

Stem | |

|

|

Caps | |

|

|

Schrader Core | |

|

|

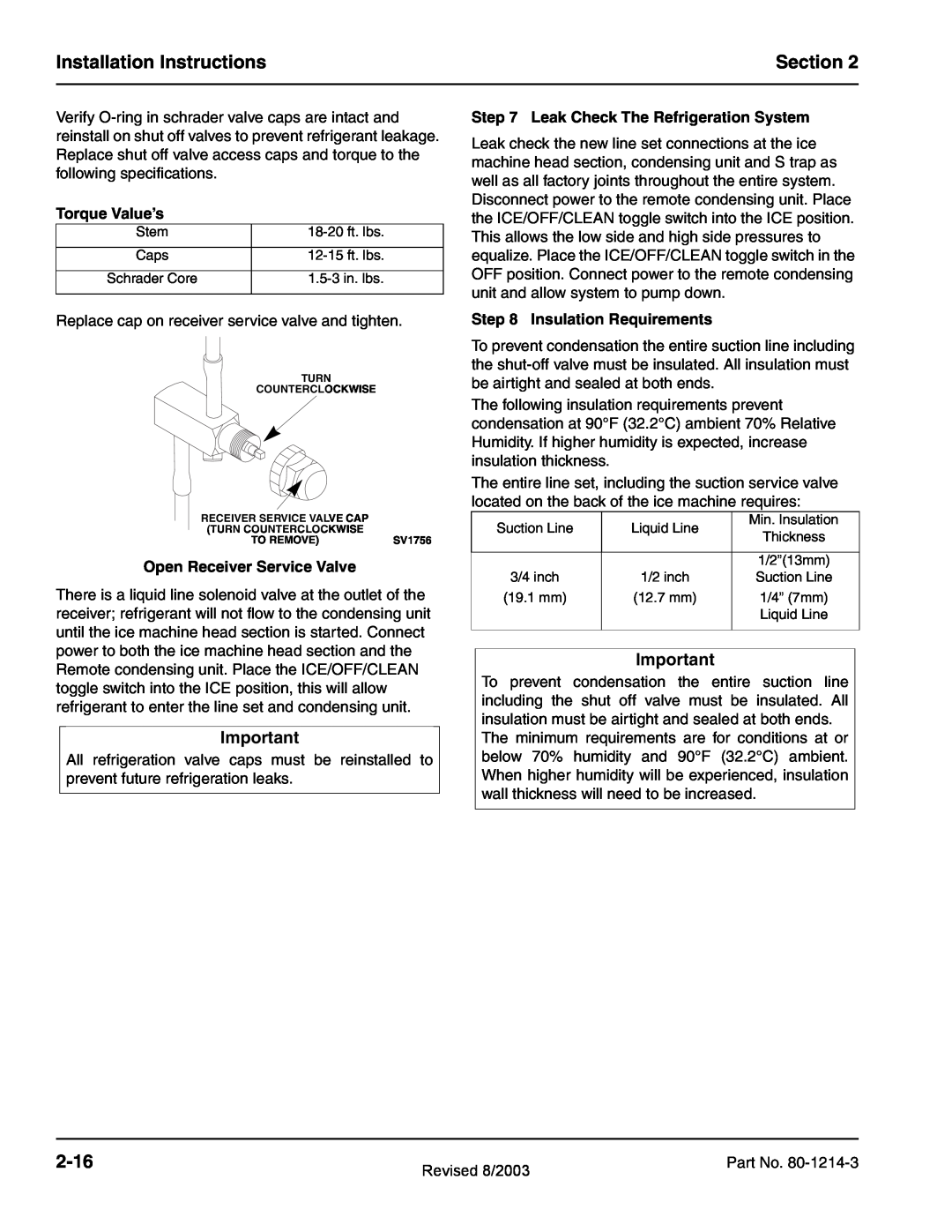

Replace cap on receiver service valve and tighten.

TURN

COUNTERCLOCKWISE

RECEIVER SERVICE VALVE CAP |

|

(TURN COUNTERCLOCKWISE |

|

TO REMOVE) | SV1756 |

Open Receiver Service Valve

There is a liquid line solenoid valve at the outlet of the receiver; refrigerant will not flow to the condensing unit until the ice machine head section is started. Connect power to both the ice machine head section and the Remote condensing unit. Place the ICE/OFF/CLEAN toggle switch into the ICE position, this will allow refrigerant to enter the line set and condensing unit.

Important

All refrigeration valve caps must be reinstalled to prevent future refrigeration leaks.

Step 7 Leak Check The Refrigeration System

Leak check the new line set connections at the ice machine head section, condensing unit and S trap as well as all factory joints throughout the entire system. Disconnect power to the remote condensing unit. Place the ICE/OFF/CLEAN toggle switch into the ICE position. This allows the low side and high side pressures to equalize. Place the ICE/OFF/CLEAN toggle switch in the OFF position. Connect power to the remote condensing unit and allow system to pump down.

Step 8 Insulation Requirements

To prevent condensation the entire suction line including the

The following insulation requirements prevent condensation at 90°F (32.2°C) ambient 70% Relative Humidity. If higher humidity is expected, increase insulation thickness.

The entire line set, including the suction service valve located on the back of the ice machine requires:

Suction Line | Liquid Line | Min. Insulation | |

Thickness | |||

|

| ||

|

|

| |

|

| 1/2”(13mm) | |

3/4 inch | 1/2 inch | Suction Line | |

(19.1 mm) | (12.7 mm) | 1/4” (7mm) | |

|

| Liquid Line | |

|

|

|

Important

To prevent condensation the entire suction line including the shut off valve must be insulated. All insulation must be airtight and sealed at both ends.

The minimum requirements are for conditions at or below 70% humidity and 90°F (32.2°C) ambient. When higher humidity will be experienced, insulation wall thickness will need to be increased.

| Revised 8/2003 | Part No. |

|

|