User Guide

Page

63230-500-225A2 PowerLogicTM Series 800 Power Meter 2011

Hazard Categories and Special Symbols

PowerLogicTM Series 800 Power Meter 63230-500-225A2 2011

Contents

Waveform Capture

Maintenance and Troubleshooting

Disturbance Monitoring PM870

Glossary

Introduction

What is a Power Meter?

Topics Not Covered In This Manual

2011 Introduction

Power Meter With Integrated Display

Power Meter Hardware

PowerLogicTM Series 800 Power Meter

Introduction 2011

Parts of the Series 800 Power Meter without display

Power Meter Without Display

Parts of the remote display Description

Power Meter With Remote Display

Electric

Power Meter Parts and Accessories

Box Contents

Series 800 Power Meter Features

Features

Firmware

PM820 PM850 PM870

Introduction 2011 Schneider Electric. All Rights Reserved

2011 Safety Precautions

Safety Precautions

Page

Operation

Power Meter Display

How the Buttons Work

Changing Values

Level

Power Meter Setup

Setup Mode Access

Date Setup

Lang Language Setup

Time Setup

Meter Setup

Comms Communications Setup

CTs Setup

Communications Default Settings Communications Setting

PTs Setup

HZ System Frequency Setup

SYS System Type Setup

Alarm Alarms Setup

Passw Password Setup

Input/Output Setup

Timer Operating Time Threshold Setup

Advan Advanced Power Meter Setup Features

ROT Phase Rotation Setup

INC Incremental Energy Interval Setup

THD Calculation Setup

VAR/PF Convention Setup

Lock Resets Setup

Alarm Backlight Setup

Bar Graph Setup

Power Demand Configuration Setup

PQ Advanced Evaluation Setup

Power Meter Resets

Initialize the Power Meter

Accumulated Energy Readings Reset

Accumulated Demand Readings Reset

Minimum/Maximum Values Reset

Display Mode Change

Accumulated Operating Time Reset

Power Meter Diagnostics

View the Meter Information

Read and Write Registers

View the Meter Date and TIme

Real-Time Readings

Metering Capabilities

2011 Metering Capabilities

One-second, Real-time Readings Reportable Range

Min/Max Values for Real-time Readings

Power Factor Min/Max Conventions

Real

Power Factor Sign Conventions

Demand Power Calculation Methods

Demand Readings

Demand Readings Reportable Range

Fixed Block

Sliding Block

Thermal Demand Example

Demand Current

Predicted Demand

Predicted demand is updated every second

Peak Demand

Generic Demand

Pulse hour second

Input Metering Demand

Accumulated Energy

Energy Readings

Accumulated Energy, Conditional

Accumulated Energy, Incremental

Configuration

Energy-Per-Shift PM810 with PM810LOG

Energy-per-shift recorded values Category Recorded Values

Values -3 to Default

Power Analysis Values

Fundamental Currents per phase

Fundamental Voltages per phase

THD-Voltage, Current

Miscellaneous

Digital Inputs

Input/Output Capabilities

Demand Synch Pulse Input

Normal Demand Mode External Synch Pulse Demand Timing

Relay Output Operating Modes

Normal

Latched

End Of Power Demand Interval

Timed

Absolute kWh Pulse

Solid-state KY Pulse Output

Wire Pulse Initiator

KWh Out Pulse

KVARh Out Pulse

Calculating the Kilowatthour-Per-Pulse Value

Fixed Pulse Output

Analog Inputs

Analog Outputs

= 0.1111 kWh/pulse

Basic Alarms

Alarms

Basic Alarm Groups

2011 Alarms

EV2Max2

Setpoint-driven Alarms

EV1Max1

Max2

Viewing Alarm Activity and History

Priorities

Types of Setpoint-controlled Functions

Schneider Electric. All Rights Reserved

Scale Groups Measurement Range Scale Factor

Scale Factors

Alarm Conditions and Alarm Numbers

Scaling Alarm Setpoints

Scale Group Register Numbers

Limit

Digital

Standard Speed Alarms 1 Second

Standard Speed

Advanced Alarm Groups

Advanced Alarms

Advanced alarm features by model

PM850 PM870

Alarm Levels

Abbreviated Test Display Name Register

Nand

Logging

Introduction

2011 Logging

Maintenance Log

Alarm Log

Alarm Log Storage

Memory Allocation for Log Files

Number

Value Stored

Registers

Data Logs

Billing Log

Alarm-driven Data Log Entries

Organizing Data Log Files PM850, PM870

Data Log

Page

Configure the Billing Log Logging Interval

2011 Logging Billing Log Register List Description

Data Type➀

Page

Waveform Capture

Waveform Capture

2011 Waveform Capture

Number Channels

Channel Selection in PowerLogic Software

How the Power Meter Captures an Event

Waveform Storage

Initiating a Waveform

63230-500-225A2 PowerLogicTM Series 800 Power Meter 2011

Disturbance Monitoring PM870

About Disturbance Monitoring

Transformer Plant C Plant D Fault

Plant a

Plant B

Capabilities of the PM870 During an Event

63230-500-225A2 PowerLogic TM Series 800 Power Meter 2011

Page

Maintenance and Troubleshooting

Power Meter Memory

Date and Time Settings

Identifying the Firmware Version, Model, and Serial Number

Viewing the Display in Different Languages

Technical Support

Heartbeat LED

Troubleshooting

CT and PT ratings, System Type, Nominal

What is Normal?

Using This Appendix

Section I-Case a

Section I Common Problems for 3-Wire and 4-Wire Systems

Section I-Case B

Section I-Case C

Section II 3-Wire System Troubleshooting

Section III-Case a

Section III 4-Wire System Troubleshooting

Section III-Case B

Section III-Case C

Section III-Case E

Section III-Case F

Section III-Case G

Readings from a 4-wire system

Troubleshooting Diagnosis

Field Example

Appendix B-Register List

Register List Access

About Registers

Floating-point Registers

How Date and Time are Stored in Registers

How Signed Power Factor is Stored in the Register

Table B-1 Date and Time Format

Table B-2 Date and Time Byte Example

Resetting Registers

Supported Modbus Commands

Table B-3 Modbus Commands

Table B-4 Register Listing-Reset Commands

Schneider Electric All Rights Reserved

Overview of the Command Interface

Appendix C-Using the Command Interface

Issuing Commands

Table C-2 Command Codes

Command

Files

Resets

Setup

Operating Outputs from the Command Interface

9020 None Enter into setup mode 9021 8001

Exit setup mode and save all changes

To save the changes, write the value 1 to register

Conditional Energy

Command Interface Control

Incremental Energy

Digital Input Control

Figure C-2 Incremental energy example

Using Incremental Energy

Setting Up Individual Harmonic Calculations

Enabling Floating-point Registers

Changing Scale Factors

Page

Power Quality Standards

Appendix D-Advanced Power Quality Evaluations

SEMI-F47/ITI Cbema Specification

Table D-2 Duration categories

PowerLogicTM Series 800 Power Meter 63230-500-225A2

Appendix D-Advanced Power Quality Evaluations

Table D-3 Categorized disturbance levels F-47 Sag levels

Table D-4 Duration categories

EN501602000 Specification

How Evaluation Results Are Reported

Table D-6 Register Entries Description Number

Power Frequency

Possible Configurations Through Register Writes

Evaluation During Normal Operation1

Supply Voltage Variations

Supply Voltage Unbalance

Evaluations During Abnormal Operation

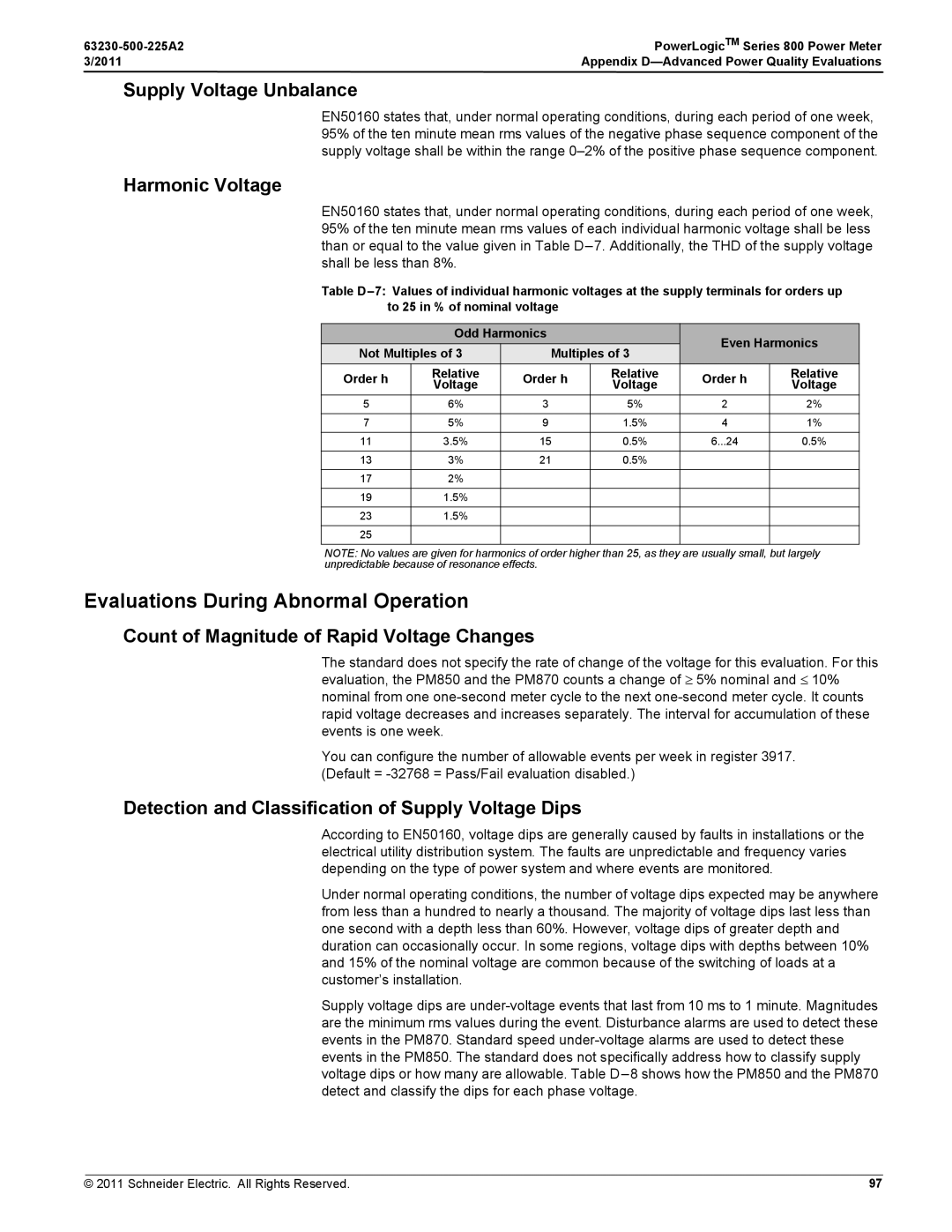

Harmonic Voltage

Count of Magnitude of Rapid Voltage Changes

Table D-8 Voltage dip classifications

Detection of Interruptions of the Supply Voltage

Table D-9 Voltage interruptions Duration t seconds

Table D-10 Over-voltages Duration t seconds

Resetting Statistics

Operation with PQ Advanced Enabled

Harmonic Calculations

Time Intervals

100 Schneider Electric. All Rights Reserved

Table D-12 Portal Register Descriptions Size Data

Portal Registers

101

Detection and Classification of Supply Voltage Dips on

102 Schneider Electric. All Rights Reserved

Detecting and Classifying Temporary Power Frequency Over

103

Alarms Allocated for PQ Advanced Evaluations

Setting Up PQ Advanced Evaluation from the Display

Terms

Glossary

63230-500-225A2 3/2011

105

106 Schneider Electric. All Rights Reserved

Abbreviations and Symbols

2011 Glossary

107

108 Schneider Electric. All Rights Reserved

Index

PowerLogicTM Series 800 Power Meter Index

63230-500-225A2 3/2011

109

110

111

PLC

112

VAR

Page

PowerLogic Power Meter 800 User Guide