AR-M351N AR-M451N

Mains Plug Wiring Instructions

Warranty

Part 1 General Information

Page

Model Product configuration AR-M351N/AR-M451N Laser printer

Product Configurations

Installation Requirements

Battery Disposal

For North America

Laser Information

For Europe

Contents

Chapter Convenient Copy Functions Specifications

Chapter

Original and paper sizes

Introduction

Meaning of R in original and paper size indications

Pamphlet Copy See Staple sort mode Job Build

Main Features

Sort mode

Copies can be collated

XY Zoom

Size Books or thick originals can be erased

Dual Page Copy

Margin Shift

Originals 1-sided Copy Sheets Originals 2-sided

Job programs

Card Shot

Mirror Image

Reverse

Interrupting a copy run

Text See Staple sort mode

Copy job in progress can be interrupted for a rush job

Saddle stitch

Auto power shut-off mode

Preheat mode

Hole punching

Copies can be punched to add holes

Part Names and Functions

Press to turn power on and off

Exterior

Module for two-sided printing

Interior

Part names and functions of peripheral devices

Barcode font kit AR-PF1

Other optional equipment

Data security kit AR-FR21, AR-FR21U

PS3 expansion kit AR-PK6

Operation panel

Touch panel

Using the touch panel

Selecting a function

Complete

Mode select key

Job screen

Job list Paper Empty in the job status display

Print JOB key

Display switching keys

MAIL/FTP key

FAX JOB key

Turning the Power on and OFF

Using the machine when the auditing mode is enabled

Auditing Mode

When the copy job is finished, press the key ACC.#-C key

Enter your account number 5 digits with the numeric keys

Managing the Machine

Loading paper in paper tray

Loading Paper

Changing the paper size in paper tray

Weight

Specifications of paper trays

Applicable special paper

Applicable plain paper

Paper that can be used for automatic two-sided printing

User type

Setting the paper type and paper size

Tray 2 and the bypass tray

Setting the paper size when a special size is loaded

Select the paper type that you wish to program or edit

Programming and editing paper types

Touch the Type Name key

Set the attributes of the paper tray

Loading paper in the multi purpose drawer

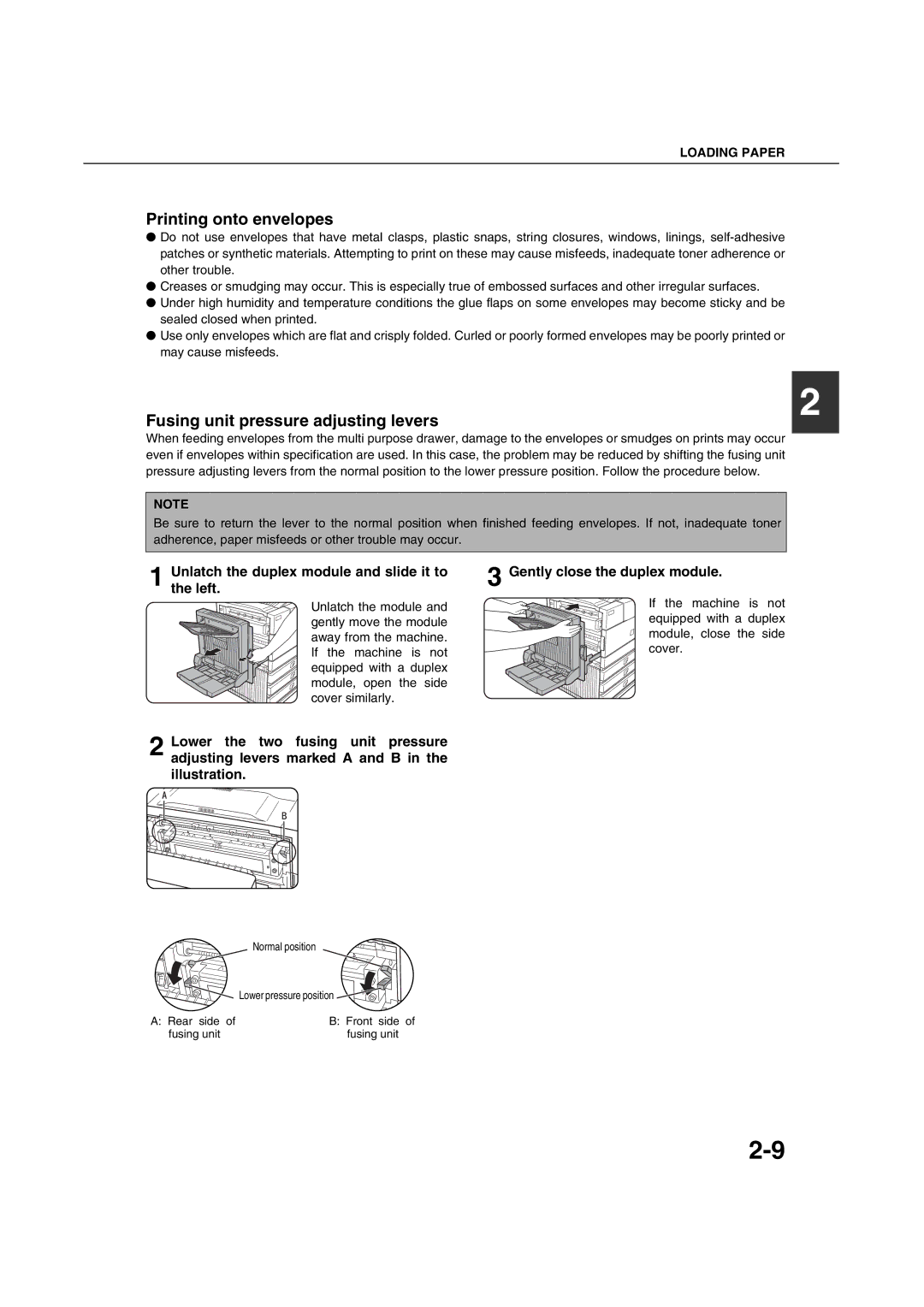

Printing onto envelopes

Fusing unit pressure adjusting levers

Unlatch the duplex module and slide it to the left

Gently close the duplex module

Specifications stand/3 x 500 sheet paper drawer

Specifications multi purpose drawer

Loading paper in the stand/3 x 500 sheet paper drawer

Loading paper in the stand/MPD & 2000 sheet paper drawer

Specifications stand/MPD & 2000 sheet paper drawer

Lower paper tray

General procedure for custom settings

Custom Settings

Touch the Clock key

More information on setting procedures

Touch the OK key To exit the settings, touch the Exit key

You will return to OK date and time setting screen

Touch the Date Format key

Default settings

About the settings

Paper tray settings

Total count

Gently remove the sealing tape from the cartridge

Replacing the Toner Cartridge

Return the cartridge lock lever Close the front cover

Push the cartridge in until it locks securely into place

Proper storage

Storage of Supplies

Supply and Consumables

Misfeed removal guidance

Misfeed Removal

Remove the misfed paper as shown in the illustrations below

Misfeed in the transport area, fusing area, and exit area

Misfeed in the bypass tray

Misfeed in the duplex module

Remove the misfed from the bypass tray

Misfeed in the paper feed area

Installation of trays in the stand/3x500 sheet paper drawer

Misfeed in paper tray

Remove the misfed paper

Misfeed in the stand/MPD & 2000 sheet paper drawer

Open the left cover of the stand/paper drawer

Gently close the duplex unit

Gently close the large capacity tray

Check location a

Removing AN Original Misfeed

Check location B Misfeed in the transfer unit

Problem Check Solution or cause

Troubleshooting

Use SHARP-recommended paper.

Sharp

Paper Other Than

PRE-PUNCHED or Using Disabling of Duplex in the key

Printed

Letter Head

Page

Peripheral Devices

Duplex Module

Specifications

Part names

Open the bypass tray

Loading paper in the bypass tray

Set the type and size of the loaded paper

Loading paper in the bypass tray is now complete

Check the list below before calling for service

Troubleshooting concerning the duplex module

Missing May be cut off or the image may not print

2 x 11R, 7-1/4 x 10-1/2

MAIL-BIN Stacker

Open the top cover

Misfeed in the mail-bin stacker

Close the paper guide

If the misfed paper is not found in step

Supplies

Finisher

Do not put pressure on the finisher particularly each tray

Offset mode

Sort mode

Group mode

Staple sort mode

Using the finisher functions

Push the staple box in until it clicks into place

Staple cartridge replacement

Open the finisher compiler

Checking the staple unit

Raise the lever at the end of the staple box

Remove the misfed paper from the stapler compiler

Removearea. the misfed paper from the output

Misfeed in the finisher

Raise the paper guide and remove the misfed paper

Open the finisher top cover Close the finisher compiler

Check Stapler Position or

Troubleshooting finisher problems

Check the staple unit. See

Staples

Or larger sizes 80 g/m2 or 20 lbs

Saddle Stitch Finisher

Sets

Saddle stitch finisher functions

Sort mode Group mode

AR-PN1A AR-PN1B*2 AR-PN1C*3 AR-PN1D*3

11R, and up to 25 sheets for

Saddle stitch function

Hole punching only if a punch module is installed

Offset Tray key

Using the saddle stitch finisher

Centre Tray key

Saddle Stitch key See

Staple cartridge replacement

Staple cartridge replacement and staple jam removal

Insert a new staple cartridge into the staple box

Push the stapler section back into the finisher

Staple jam removal

Disposal of hole punch scrap

13Reinstall the staple box

Front

Turn roller rotating knob a in the direction

Rotating roller rotating

Misfeed in the saddle stitch finisher

Knob B knob B releases Caught paper

Remove the paper gently, taking care not to tear it

12Remove any misfed paper from the saddle stitch tray

Troubleshooting concerning the saddle stitch finisher

Part 2 Copier Operation

Page

Making Copies

Automatic Document Feeder

Size and weight of acceptable originals

Acceptable originals

Using the document glass

Using the automatic document feeder

Placing Originals

Original size detection function

Automatic copy image rotation rotation copying

Standard original placement orientations

Example

Checking the Size of a Placed Original

Manually setting the scanning size

Touch the Original key

Touch the desired original size key

Storing or deleting an original size

STORING, DELETING, and Using Original Sizes

Touch the Custom Size key

Touch the STORE/DELETE key

Making copies with the automatic document feeder

Normal Copying

Sided copies of 1-sided originals

Touch the 2-SIDED Copy key

To cancel copying

Select the desired output mode

Use the numeric keys to set the desired number of copies

If needed, touch the File key or the Quick File key

Sorting copies into sets

Copy output sort and group

Grouping copies by

Equipment installed

Select the desired copy mode

Display Will Vary

Depending

Copying from the document glass

Ensure that the 1-sided to 1-sided copy mode is selected

Display. If an Icon

Touch the READ-END key

Select9. the desired output mode. Press the Start key

Touch the 2-SIDED Copy key.4 Touch the OK key

Automatic two-sided copying from the document glass

Perform steps 3 to 8 on pages 4-11

Automatic exposure adjustment

Adjusting the Exposure

Touch the Exposure key

Automatic selection auto image

REDUCTION/ENLARGEMENT/ZOOM

Touch the Copy Ratio key

Manual selection preset copy ratios/zoom

To return the ratio to 100%

Auto paper select display

Touch the X key

Touch the XY Zoom key

Touch the Y key

To cancel an X or Y zoom setting

Load the special paper in the bypass tray

Special Papers

Touch the Paper Select key

Set the type and size of paper loaded in the bypass tray

Convenient Copy Functions

Special Modes

General procedure for using special functions

Touch the Special Modes key

Touchmode. the key for the desired special

Touch the Margin Shift key on the special modes screen

Margin shift

Select the shift direction

Set the shift amount as needed and touch the OK key

Adjust the amount of erase and touch the OK key

Select the desired erase mode

Erase

Touch the Erase key on the special modes screen

Ensure that 8-1/2 x 11 A4 size paper is selected

Dual page copy

Touch the Dual page Copy key on the special modes screen

Place the originals on the document glass

Pamphlet copy

12Whenfeeder using the automatic document

When using the document glass

Select the paper tray for the cover

Touch the JOB Build key on the special modes screen

Job build

JOB Build

Touch the Tandem Copy key on the special modes screen

Tandem copy

Set the number of copies with the numeric keys

Server machine and client machine

Press the Start key

Covers/inserts

Preparations for using covers and inserts

About the explanations of covers and inserts

Example of adding covers and inserts

To cancel covers/inserts settings

Procedure for inserting front and back cover paper

Touch the Cancel key in the screen of step

Selectpaper. the tray used for the front cover

Select the tray used for insertion type a

Procedure for adding inserts

Set the insertion conditions for insertion type a

13Press the Start key

Checking, editing, and deleting cover/insert pages

When you have finished checking Pages, touch the OK key

Touch the page Layout key

Set covers/inserts pages are shown

Examples of covers and inserts

Symbols used for covers and inserts

Covers One-sided copying of one-sided originals

Covers Two-sided copying of one-sided originals

Covers One-sided copying of Two-sided originals

Covers Two-sided copying of two-sided originals

Inserts One-sided copying of two-sided originals

Inserts One-sided copying of one-sided originals

1st 2nd 3rd

Transparency film with insert sheets

Touch the key to display the tray settings screen of tray

Load transparency film into the tray

Touch the TYPE/SIZE key

Select the tray

Multi shot

Paper

Step

Touch the OK key in the special modes screen

Select the layout

Scan the original pages

Book copy

Opened last page and inside of back cover

You will return to

Card shot

Place the original on the document glass

Touch the outer OK key

Follow steps 4 through 6 of Copying from the document glass

10Touch the READ-END key

Reverse

Mirror image

Reverse

Date print

Print menu

Stamp

Numbering

To display the special modes screen

Common operation procedure for using the print menu

Select the print position

Select the print menu

Printing in combination with other special functions

To cancel print menu

Check the print layout if needed page 5

Printing the date on copies

To cancel a date print setting

Select the date format

Check the date and format

To cancel a stamp setting

Adjust the exposure as needed Select the desired stamp size

Printing a stamp reverse text on copies

Select the stamp that you wish to print

Select the page number format

Printing the page number on copies

Touch the Manual key

Selected format is

10Touch the OK key

Number printing during one-sided copying 5 originals

Examples of page number printing

Number printing during two-sided copying 9 originals

1st 2nd 3rd 4th 5th Setting Value Insert Front Back

Printing entered text on copies

To cancel a text setting

Editing and deleting stored text

Storing text sequences

Touch the Back key

Touch the text key that you wish to edit or Delete.5

Up to 14 characters of the print text appears in the key

Checking and changing the print layout

Storing a job program

STORING, Using and Deleting JOB Programs

Number Keys Which

Job Programs Are Already Stored Highlighted

Deleting a stored job program

Calling up a job program

Document glass

Interrupting a Copy RUN

Page

Machine Maintenance For Copying

Cleaning the main charger of the photoconductive drum

User Maintenance

Close the front cover and switch on the power switch

Troubleshooting

Page

Document Filing Function

Document filing function

Overview

Data flow

Main Folder

Main folder

Quick File folder

Custom folder

Attributes of saved files

Look at the operation panel

Mode select keys

Saving files

Touch panel see the next

Document filing icons

Quick File

Saving a Document Image File

Touch the Quick File key in the main screen

Presspanel. the Start key on the operation

Touch the File key in the main screen

Filing

Touch the User Name key

Touch the File Name key

12Enterkeys. a 5-digit password with the numeric

11Touch the Password key 15Touch the OK key

16Presspanel. the Start key on the operation

13Touch the OK key

Touch the key of the folder that contains the desired file

Print jobs

Touch the key of the operation that you wish to perform

Property Change key see

Touch the File Information key

Scan Save

You will return to the screen of step

12Touch the key of the desired resolution

11Touch the Resolution key

16Touch the OK key

17Placekey. the original and touch the Start

Erase key see

Using special functions for scan save

JOB Build key see

Card Shot key see

Procedure for searching for a file

Calling UP and Using a File

Searching for and calling up a saved file

Searching by user name

To perform an operation using the file, go to on

Operation using the file, go to on

Touch the Search Start key

General procedure for using a saved file

Calling up and using a saved file

Touch the desired file key

Print

Send

Property change

Send Settings key SUB Address key or Address Entry key

Touch the key of the desired attribute

Restrictions on changing the attribute

Move

Touch the Cancel key

Delete

Detail

Touch the key of the desired file

Press the JOB Status key

Touch the Call key

Creating, editing, and deleting user names and folders

Press the Custom Settings key Touch

Control key

Go to the page indicated below for the selected operation

Programming a user name

Touch the Password key

Touch the Initial key

Touch the Exit key

Editing and deleting a user name

Touch the Folder Name key

Creating a custom folder

Editing/deleting a custom folder

Entering alphabetical characters

Entering Characters

Enter the desired number or symbol

Entering numbers and symbols

Numbers and symbols that can be entered are as follows

Screen 1/2

Different folder or set it to Protect

Selecting Half Tone after setting

Property

Change page 7-18 to change

This chapter contains useful information about the machine

Specifications

Automatic document feeder

Specifications

Machine tray tray

Specifications

List of Combination of Peripheral Devices

Numerics

Index

Mode select keys

General procedure for using special functions

26 to

5-2, 5-4

Part names

5-29, 5-34 to

29 to

Saving a document image file

13, 1-14, 7-4

Troubleshooting

Transparency film 2-4, 2-10, 2-16, 4-20

General information 23 to

Page

Page

Page

2004J KS1 TINSE2797FCZZ

Sharp Corporation