7-2 Alarms

The format for all station alarms is “Station n [alarm text],” for example, “Station 12 receiver low level.” The format for all pump alarms is “Pump n [alarm text].” Any alarm that does not start with “Station” or “Pump” is a system alarm.

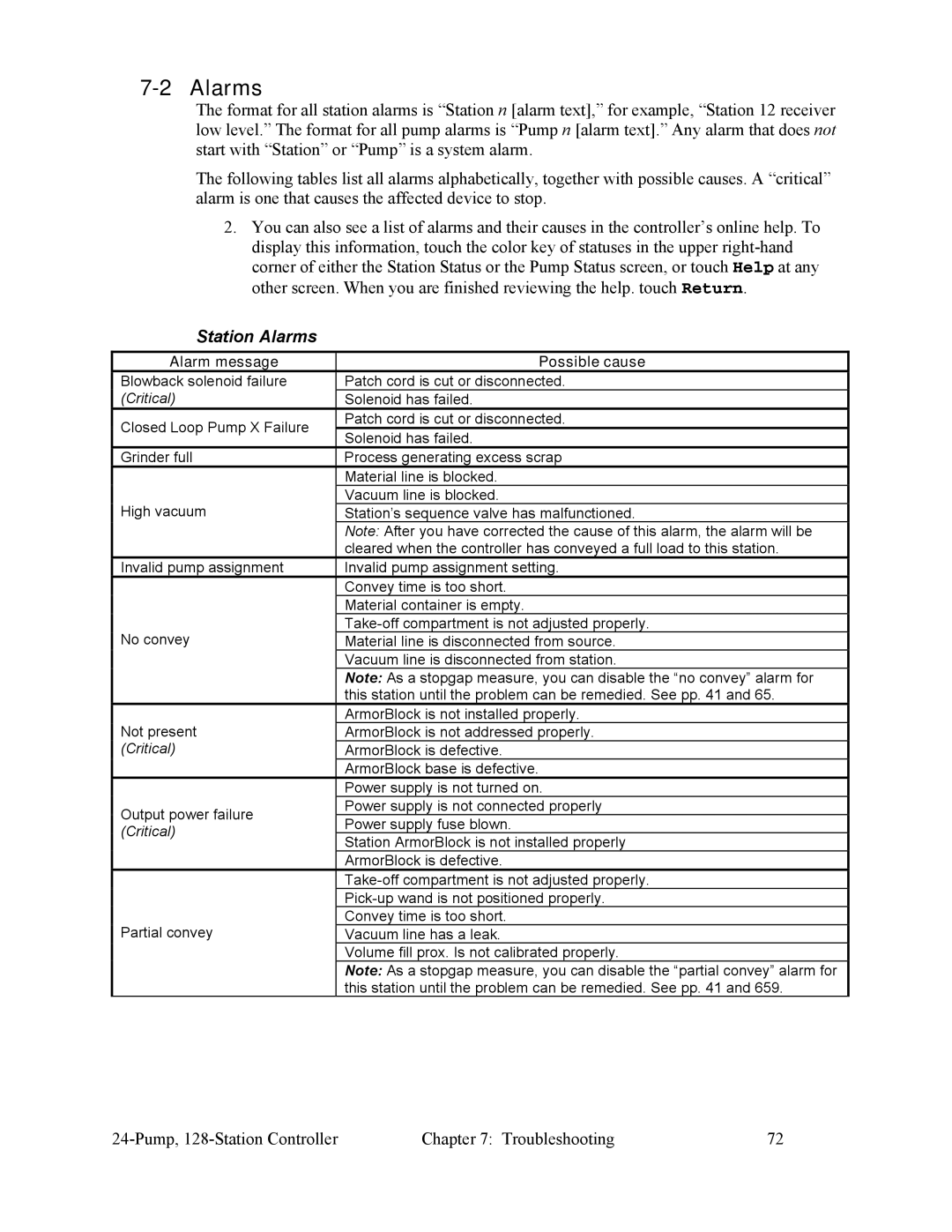

The following tables list all alarms alphabetically, together with possible causes. A “critical” alarm is one that causes the affected device to stop.

2.You can also see a list of alarms and their causes in the controller’s online help. To display this information, touch the color key of statuses in the upper

Station Alarms

Alarm message | Possible cause | |

Blowback solenoid failure | Patch cord is cut or disconnected. | |

(Critical) | Solenoid has failed. | |

Closed Loop Pump X Failure | Patch cord is cut or disconnected. | |

Solenoid has failed. | ||

| ||

Grinder full | Process generating excess scrap | |

| Material line is blocked. | |

High vacuum | Vacuum line is blocked. | |

Station’s sequence valve has malfunctioned. | ||

| Note: After you have corrected the cause of this alarm, the alarm will be | |

| cleared when the controller has conveyed a full load to this station. | |

Invalid pump assignment | Invalid pump assignment setting. | |

| Convey time is too short. | |

| Material container is empty. | |

No convey | ||

Material line is disconnected from source. | ||

| Vacuum line is disconnected from station. | |

| Note: As a stopgap measure, you can disable the “no convey” alarm for | |

| this station until the problem can be remedied. See pp. 41 and 65. | |

Not present | ArmorBlock is not installed properly. | |

ArmorBlock is not addressed properly. | ||

(Critical) | ArmorBlock is defective. | |

| ArmorBlock base is defective. | |

| Power supply is not turned on. | |

Output power failure | Power supply is not connected properly | |

Power supply fuse blown. | ||

(Critical) | ||

Station ArmorBlock is not installed properly | ||

| ||

| ArmorBlock is defective. | |

| ||

| ||

Partial convey | Convey time is too short. | |

Vacuum line has a leak. | ||

| Volume fill prox. Is not calibrated properly. | |

| Note: As a stopgap measure, you can disable the “partial convey” alarm for | |

| this station until the problem can be remedied. See pp. 41 and 659. |

Chapter 7: Troubleshooting | 72 |