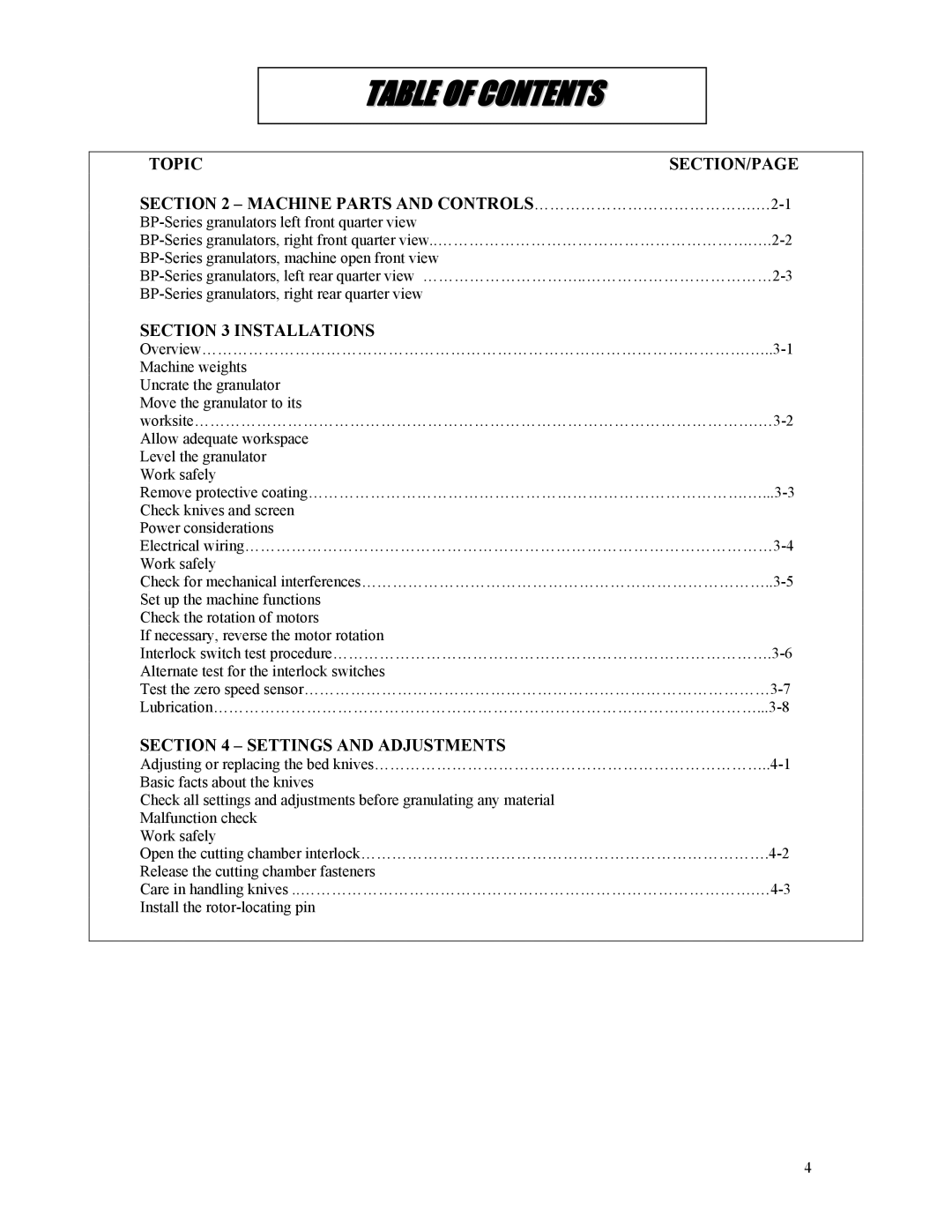

| TABLE OF CONTENTS |

|

|

|

|

|

|

|

TOPIC | SECTION/PAGE | |

SECTION 2 – MACHINE PARTS AND

SECTION 3 INSTALLATIONS

Machine weights Uncrate the granulator Move the granulator to its

Allow adequate workspace Level the granulator Work safely

Remove protective

Check knives and screen Power considerations

Electrical

Work safely

Check for mechanical

Set up the machine functions Check the rotation of motors

If necessary, reverse the motor rotation

Interlock switch test

Alternate test for the interlock switches

Test the zero speed

SECTION 4 – SETTINGS AND ADJUSTMENTS

Adjusting or replacing the bed

Basic facts about the knives

Check all settings and adjustments before granulating any material Malfunction check

Work safely

Open the cutting chamber

Release the cutting chamber fasteners

Care in handling

Install the

4