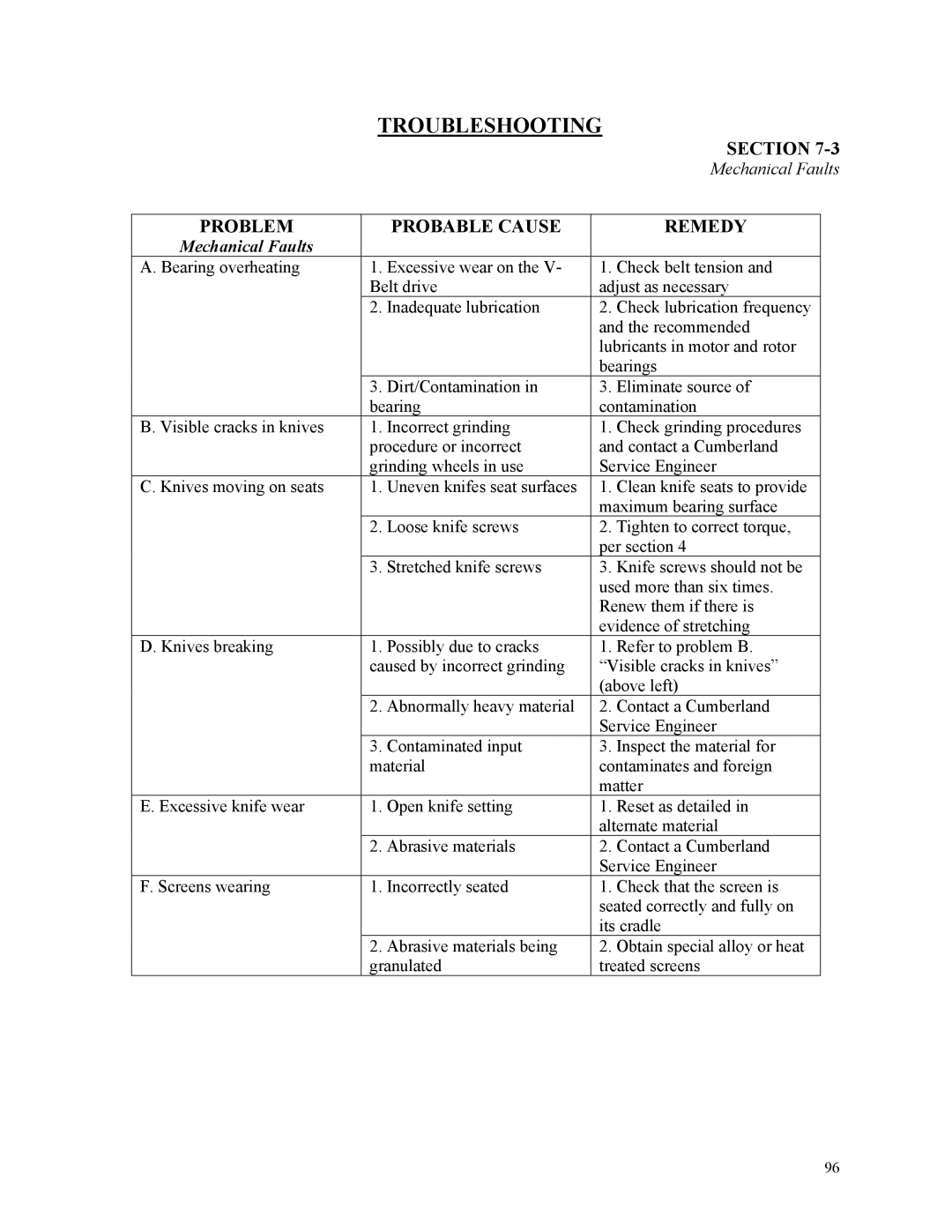

TROUBLESHOOTING

|

|

|

| SECTION | |

|

|

|

| Mechanical Faults | |

|

|

|

|

|

|

PROBLEM |

| PROBABLE CAUSE |

| REMEDY | |

Mechanical Faults |

|

|

|

|

|

A. Bearing overheating | 1. | Excessive wear on the V- | 1. | Check belt tension and |

|

| Belt drive | adjust as necessary |

| ||

| 2. | Inadequate lubrication | 2. | Check lubrication frequency |

|

|

|

| and the recommended |

| |

|

|

| lubricants in motor and rotor |

| |

|

|

| bearings |

| |

| 3. | Dirt/Contamination in | 3. | Eliminate source of |

|

| bearing | contamination |

| ||

B. Visible cracks in knives | 1. | Incorrect grinding | 1. | Check grinding procedures |

|

| procedure or incorrect | and contact a Cumberland |

| ||

| grinding wheels in use | Service Engineer |

| ||

C. Knives moving on seats | 1. | Uneven knifes seat surfaces | 1. | Clean knife seats to provide |

|

|

|

| maximum bearing surface |

| |

| 2. | Loose knife screws | 2. | Tighten to correct torque, |

|

|

|

| per section 4 |

| |

| 3. | Stretched knife screws | 3. | Knife screws should not be |

|

|

|

| used more than six times. |

| |

|

|

| Renew them if there is |

| |

|

|

| evidence of stretching |

| |

D. Knives breaking | 1. | Possibly due to cracks | 1. | Refer to problem B. |

|

| caused by incorrect grinding | “Visible cracks in knives” |

| ||

|

|

| (above left) |

| |

| 2. | Abnormally heavy material | 2. | Contact a Cumberland |

|

|

|

| Service Engineer |

| |

| 3. | Contaminated input | 3. | Inspect the material for |

|

| material | contaminates and foreign |

| ||

|

|

| matter |

| |

E. Excessive knife wear | 1. | Open knife setting | 1. | Reset as detailed in |

|

|

|

| alternate material |

| |

| 2. | Abrasive materials | 2. | Contact a Cumberland |

|

|

|

| Service Engineer |

| |

F. Screens wearing | 1. | Incorrectly seated | 1. | Check that the screen is |

|

|

|

| seated correctly and fully on |

| |

|

|

| its cradle |

| |

| 2. | Abrasive materials being | 2. | Obtain special alloy or heat |

|

| granulated | treated screens |

| ||

96