MACHINE AND CONTROLS

SECTION 2-1

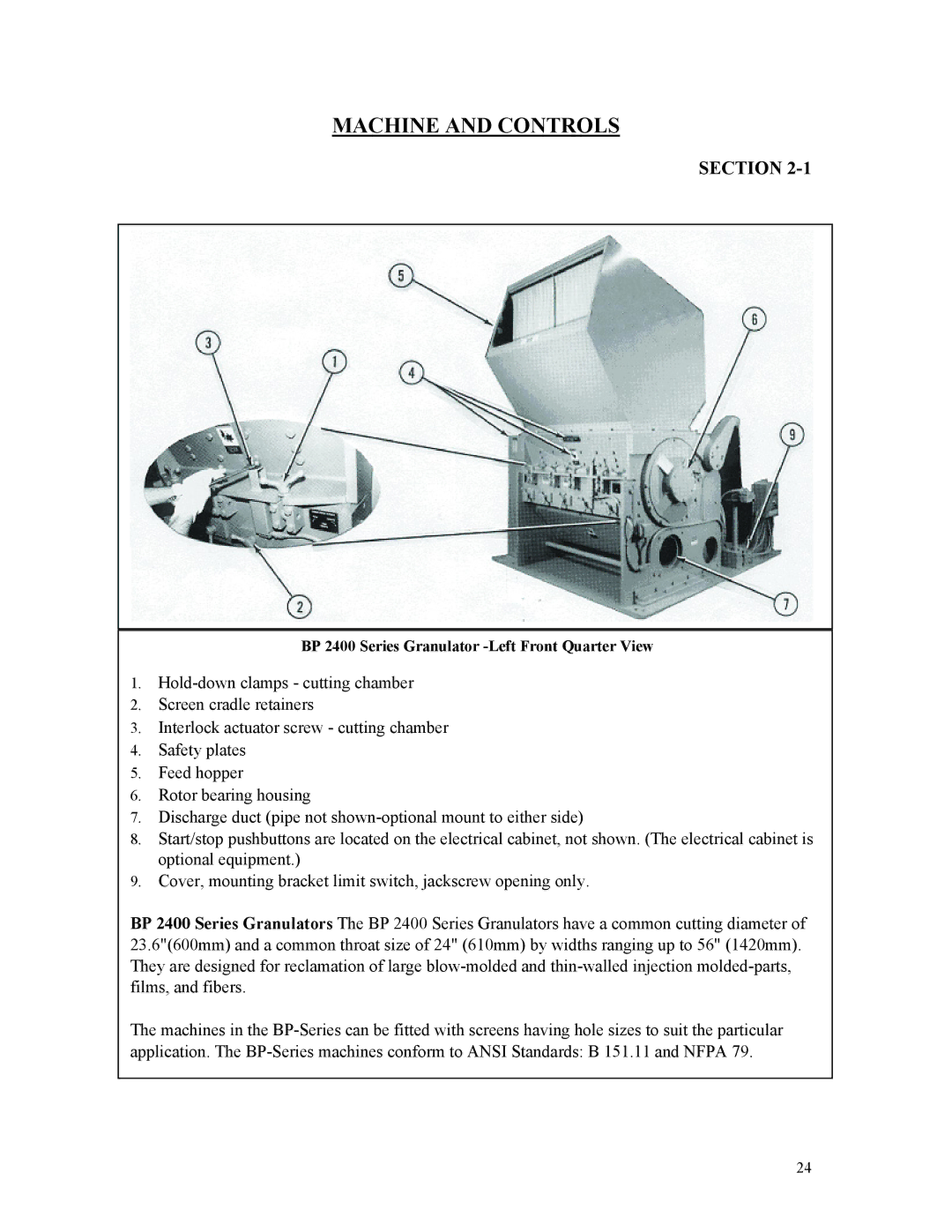

BP 2400 Series Granulator

1.

2.Screen cradle retainers

3.Interlock actuator screw - cutting chamber

4.Safety plates

5.Feed hopper

6.Rotor bearing housing

7.Discharge duct (pipe not

8.Start/stop pushbuttons are located on the electrical cabinet, not shown. (The electrical cabinet is optional equipment.)

9.Cover, mounting bracket limit switch, jackscrew opening only.

BP 2400 Series Granulators The BP 2400 Series Granulators have a common cutting diameter of 23.6"(600mm) and a common throat size of 24" (610mm) by widths ranging up to 56" (1420mm). They are designed for reclamation of large

The machines in the

24