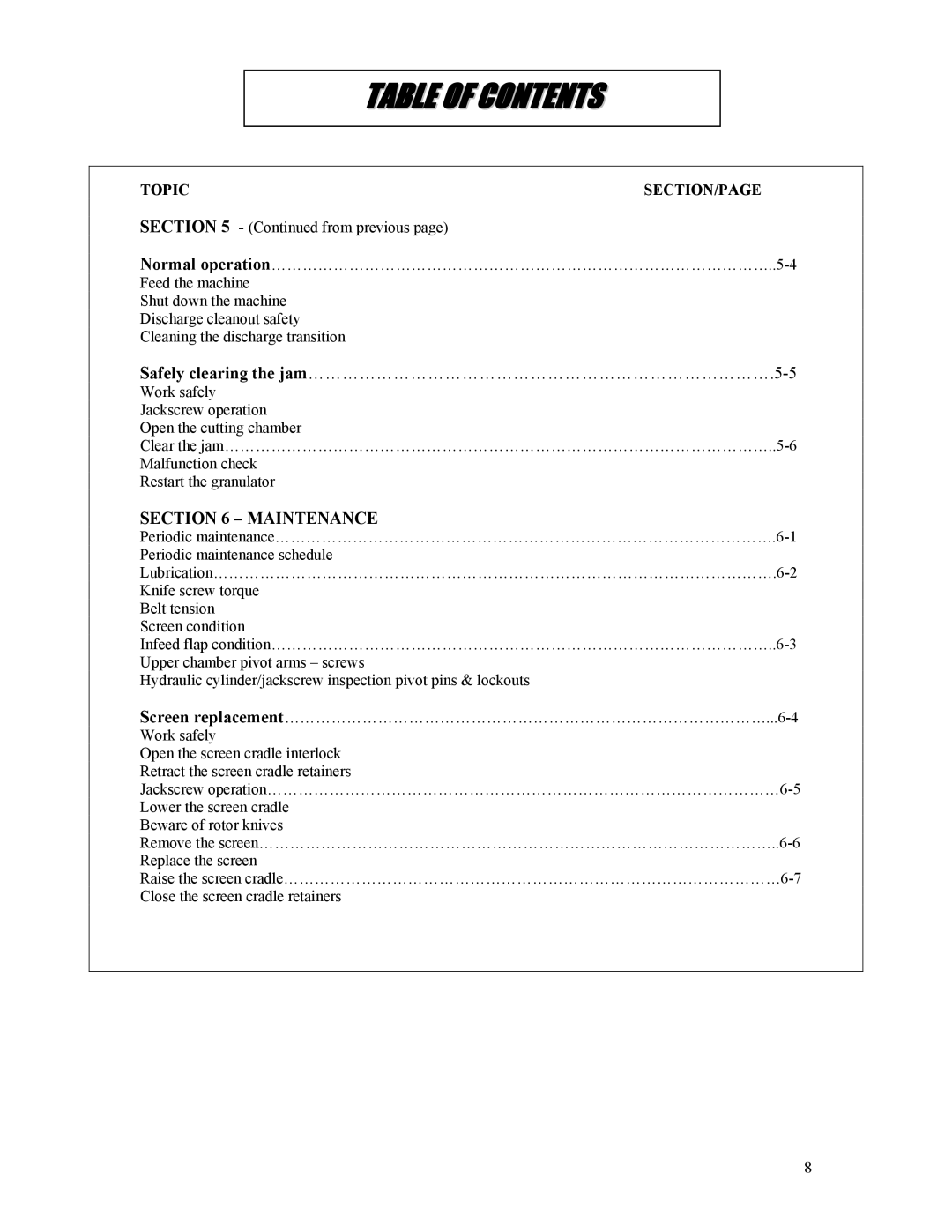

TABLE OF CONTENTS

TOPIC | SECTION/PAGE |

SECTION 5 - (Continued from previous page) |

|

Normal

Feed the machine

Shut down the machine Discharge cleanout safety Cleaning the discharge transition

Safely clearing the jam……………………………………………………………………….5-5

Work safely Jackscrew operation Open the cutting chamber

Clear the

Malfunction check Restart the granulator

SECTION 6 – MAINTENANCE

Periodic

Periodic maintenance schedule

Knife screw torque Belt tension Screen condition

Infeed flap

Upper chamber pivot arms – screws

Hydraulic cylinder/jackscrew inspection pivot pins & lockouts

Screen

Work safely

Open the screen cradle interlock Retract the screen cradle retainers

Jackscrew

Lower the screen cradle Beware of rotor knives

Remove the

Replace the screen

Raise the screen

Close the screen cradle retainers

8