Data Cartridge Inspection Procedure | SDLT 600 Product Manual |

|

|

A.3 Data Cartridge Inspection Procedure

Ensure your data cartridge backup solution performs reliably by following the Visual Mechanical Inspection (VMI) procedures described in this subsection. These steps will help you identify any potential data cartridge problems, and will prevent accidental loss of data or damage to your SDLT 600 tape drive system.

You should do an inspection if any of these conditions occur:

•As a general practice whenever you change or load a new data cartridge.

•If a data cartridge is dropped or subjected to some hard physical shock.

•If the SDLT 600 tape drive becomes inoperable after loading a data cartridge.

•If you receive a shipment of data cartridges that show any sign of shipping damage.

Follow these steps to visually inspect an Super DLTtape I or Super DLTtape II data cartridge:

1.Remove the data cartridge from its protective plastic case.

2.Check for loose debris attached to the shell, and for other contamination (oily, slimy, or sticky substances) that may have built up on the surface of the shell.

3.Check the data cartridge for any obvious cracks or other physical damage to the shell. Rotate the data cartridge in your hands, looking for broken or missing parts.

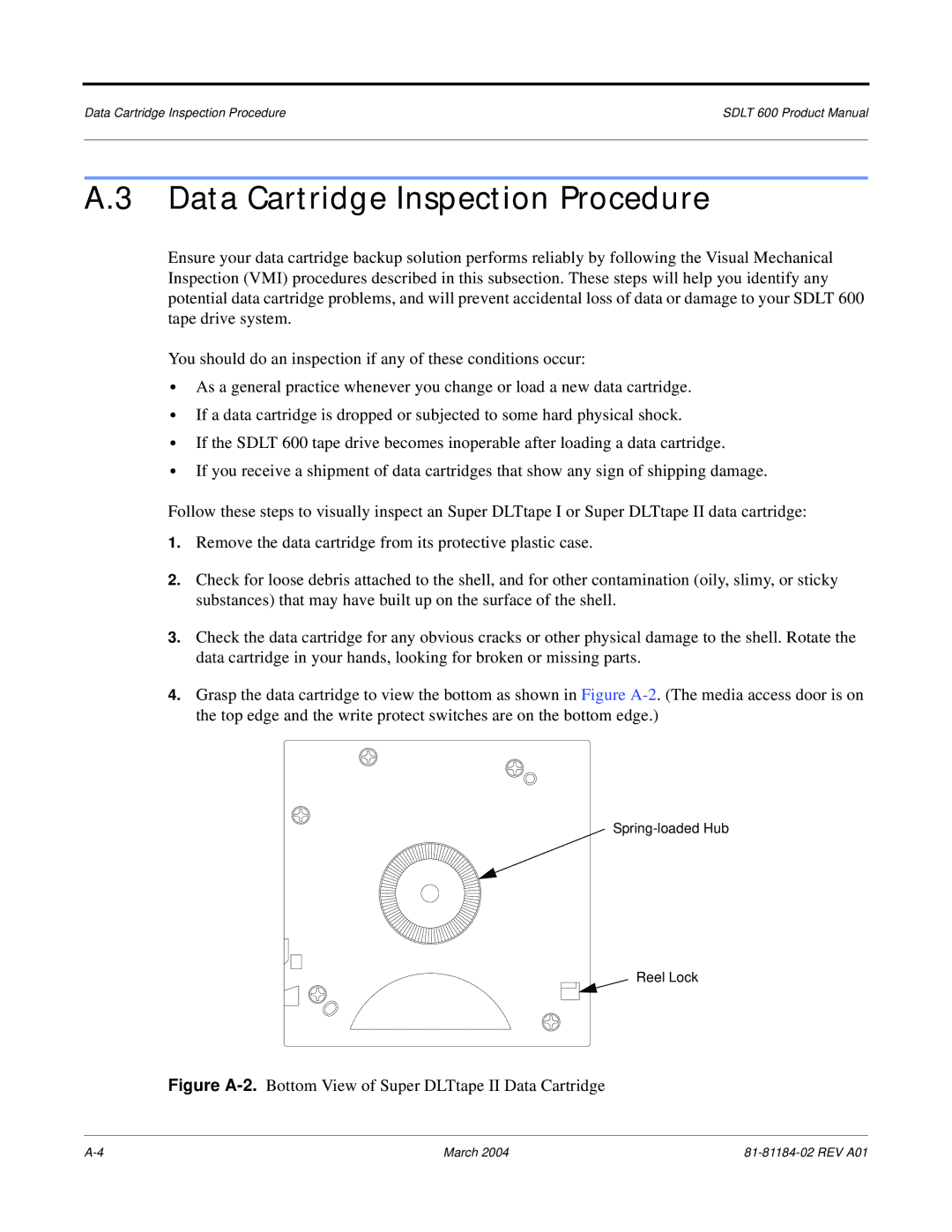

4.Grasp the data cartridge to view the bottom as shown in Figure

Spring-loaded Hub

Reel Lock

Figure A-2. Bottom View of Super DLTtape II Data Cartridge

March 2004 |