Serial Numbers

Page

Contents

Replaceable Parts

Exclusive Remedies

Warranty

Limitation Of Warranty

Certification

Printing History

Safety Symbols

Declaration of Conformity

Page

Page

Page

E1445A Arbitrary Function Generator

Introduction

Safety Considerations

General Information

Initial Inspection

Inspection Shipping

Shipping

Sales and Support Office or Service Center

Description

Specifications

Environment Temperature Humidity

Environment

Recommended Test Equipment Instrument Requirements Use Model

Recommended Test Equipment

General Information

Verification Tests

Functional Verification

Example programs, these commands would appear as follows

Functional Verification Self-Test

Remove any connections to the AFG front panel Reset the AFG

Execute the AFG self-test

Functional Verification Ref In/Marker Out Test

Set up equipment as shown in Figure

Verify that the scope shows a 10 MHz squarewave

Functional Verification Start Arm In Test

Start Arm In Test Setup

Verify that a 1 MHz sinewave appears on the scope

Functional Verification Start Arm In Test cont’d

Functional Verification Gate In Test

Set up the equipment as shown in Figure

Functional Verification Gate In Test cont’d

Purpose of this test is to check the output relay

Set up the AFG to output a 1 MHz sinewave

Verify that no signal appears on the scope

Functional Verification Output Relay Test

Clear Screen

Functional Verification

On next

10! RE-STORE Functest

Clear Screen Print SELF-TEST

Subend

Repeat

Print Start ARM Test

Clear Screen Print REF IN/MARKER OUT Test

Print Gate in Test

OFF KBD

Wait

Print Output Relay Test

Pause

Disp

Performance Verification

Operation Verification

Test # Test Name

Delete all sequences and segments from memory

Test 2-1 DC Zeros

Set the AFG output amplitude

Set up the AFG to output the waveform defined above

Test 2-1 DC Zeros cont’d

Create a user-defined waveform made up of zeros

Test 2-1 DC Zeros cont’d

Print ATTEN,FILTER,AMPLITUDE

Pause Clear Screen

END Select

Case

Next

Test 2-2 DC Accuracy

Set up the AFG to output a DC signal

10! RE-STORE Dclevels

Test 2-2 DC Accuracy cont’d

This program performs the DC Accuracy test

DC Accuracy Test Points Amplitude Filter Test Limits Volts

END

Print FILTER,AMPLITUDE

Test 2-3 DC Offset

If necessary, change the AFG output amplitude

Test 2-3 DC Offset cont’d

DC Offset Test Points Amplitude Test Limits Volts

10! RE-STORE Dcoffset

This program performs the DC Offset Test

Print AMPLITUDE, Offset

Disp Voutold=Vout

Test 2-4 AC Accuracy

Set up the AFG to output a 1 kHz sinewave

Test 2-4 AC Accuracy cont’d

10! RE-STORE Aclevels

This program performs the AC Accuracy Test

For I=1 to Select FilterI

Test 2-5 AC Flatness 250 kHz Filter

Equipment Setup for Test 2-5 and Test

Set the AFG output

Set the AFG output to the reference frequency 1 kHz

Frequency Test Limits DB error

Error relative to 1 kHz

Set AFG output to the reference frequency 1 kHz

Test 2-6 AC Flatness 10 MHz Filter

Test 2-6 AC Flatness 10 MHz Filter cont’d

Set up the Power Meter

Connect the equipment as shown in Figure

Test 2-6 AC Flatness 10 MHz Filter cont’d

Frequency Test Limits ±dB error

Abort the waveform if it has been previously initiated

Test 2-7 Frequency Accuracy

Set marker source to Rosc or TRIG, as specified in Table

Test 2-7 Frequency Accuracy cont’d

This program performs the Frequency Accuracy Test

Add aging rate of ±20 ppm/year

10! RE-STORE Oscfreq

END if

Rosc = INT1

Else

Rosc = INT2

Set the AFG to output a square wave

Test 2-8 Duty Cycle

Duty Cycle Test Points Frequency Test Limits Range Sec

Test 2-8 Duty Cycle cont’d

Set the AFG frequency range as specified in Table

Set AFG output frequency

10! RE-STORE Dutycycle

This program performs the Duty Cycle Test

Data MIN,MAX,MIN,MAX

410 !Take readings here Print Output Frequency =FreqI Hz

Test 2-9 Total Harmonic Distortion

10. Equipment Setup for Test 2-9 and Test

Where

Test 2-9 Total Harmonic Distortion cont’d

THD Test Points

This program performs the Total Harmonic Distortion Test

10 ! RE-STORE Sinethd

Output @AfgVOLT &Dbmout$ Set AFG output

Return Subend

Subexit

Print Fundamental

Return

Test 2-10 Spurious/Non-Harmonic Distortion

Description Equipment Setup

Test 2-10 Spurious/Non-Harmonic Distortion cont’d

10 ! RE-STORE Nonharm

This program performs the Spurious/Non-harmonic Test

400 !---------- Perform test For I=1 to

Performance Test Test Equipment

Performance Test Record

Test Accuracy Ratio TAR

11. Performance Test Record for the Agilent E1445A Page 1

11. Performance Test Record for the Agilent E1445A Page 2

TAR

11. Performance Test Record for the Agilent E1445A Page 3

11. Performance Test Record for the Agilent E1445A Page 4

11. Performance Test Record for the Agilent E1445A Page 5

11. Performance Test Record for the Agilent E1445A Page 6

11. Performance Test Record for the Agilent E1445A Page 7

Verification Tests

Required Equipment Recommended Environment

Calibration Commands

CALibrationSECureSTATe mode,code enables

Calibration Commands cont’d

Determine the AFG’s firmware revision

Disabling Calibration Security Shown in secured position

Defeating Calibration Security

DC Adjustment Setup

DC Adjustment Procedure

Enable calibration on the AFG

DC Adjustment Procedure cont’d

AFG will return a 1 when ready

DC Calibration Points DMM Settings Changes only

DMM Range Setting for Cal Points 41 Absolute Value DC Offset

10 ! RE-STORE Dcadjust

Case =1

Stop

Case Else

Disable calibration security on the AFG

AC Flatness Adjustment Procedure 250 kHz Filter

AC Flatness Adjustment Procedure 10 MHz Filter

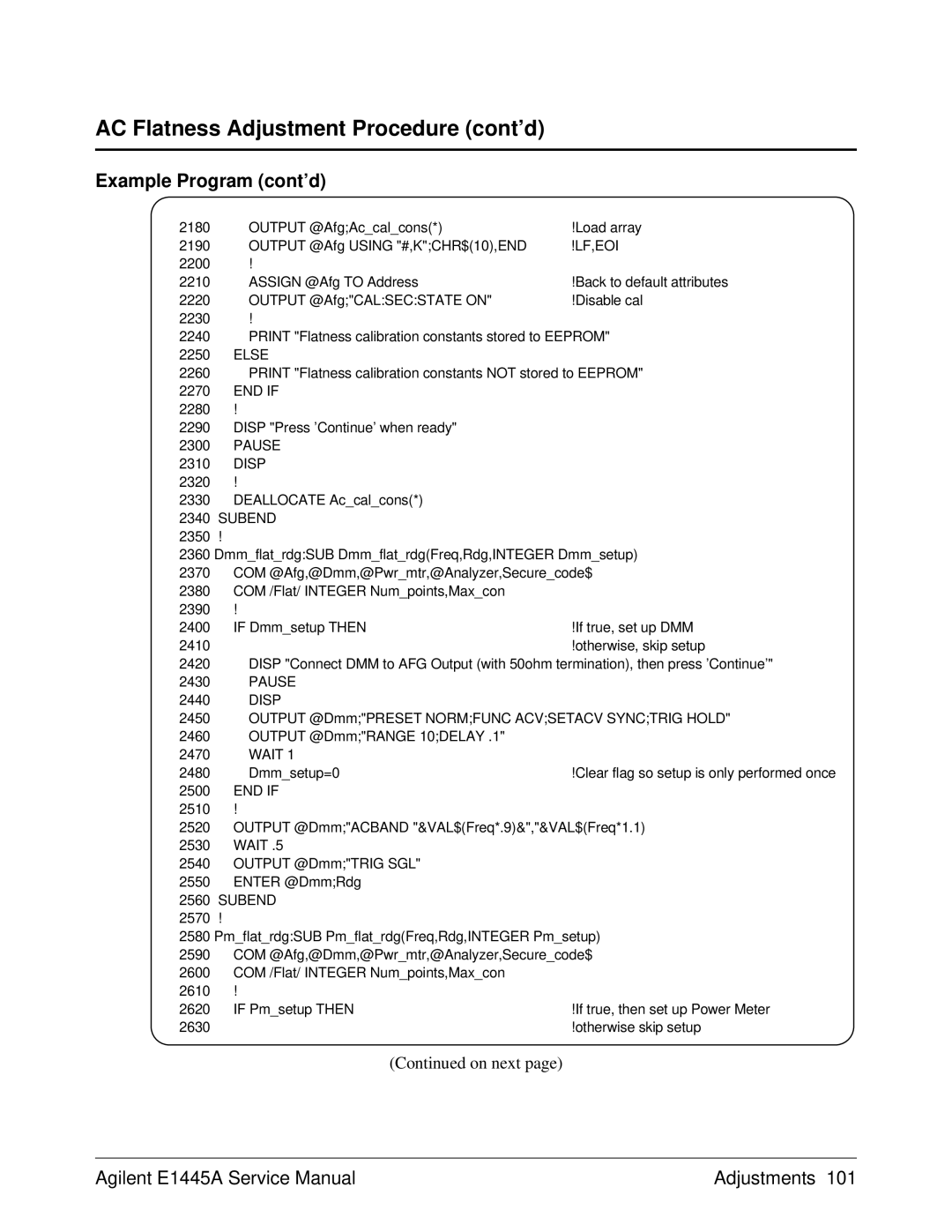

Adjustment Procedure cont’d

AC Flatness Adjustment Procedure 10 MHz Filter cont’d

320 !CLOSE I/O Paths

AC Flatness Adjustment Procedure cont’d

250 !RESET Instruments

10! RE-STORE Acflat

470 480 !---------- Initialize variables

Printer is CRT

Offsetfactor=Dmmref

LDSTBIND,0

PHASEA1,0

LF,EOI

Data 7E6

Print Pass Parameter not Dimensioned Large Enough

Beep

SET CAL Constant Scale Factors

Check for Valid CAL

Print Turnover DAC OUT of Range

Print Gain DAC OUT of Range

SUB SysterrAddress

Block1=N

SUB Securitycode

Fnend

Skew DAC Adjustment Setup

Skew DAC Adjustment Procedure

Enable calibration security on the AFG

Skew DAC Adjustment Procedure cont’d

Set up the AFG to output an 11 dBm, 4 MHz sinewave

Load an initial value of 128 into the delay DAC

10 ! RE-STORE Skewcal

Print Print CONSTANT, Reading

Set variables for next loop

Check firmware rev

Meas2ndharmSUB Meas2ndharmReading

Adjustments

Exchange Assemblies

Replaceable Parts List

Mechanical Parts

Agilent E1445A Replaceable Parts

Agilent E1445A Reference Designators

Agilent E1445A Code List of Manufacturers

E1445A Replaceable Parts

Equipment Required

Service

Testing the Assembly

Identifying Problem

Agilent E1445A Tests/Checks

Checking for Heat Damage

Removing BNC Connectors

Precautions

Repair Maintenance Guidelines

Service

Page

E1445-90011