Controls, Start-Up, Operation, Service, and Troubleshooting

Contents

Contents

Safety Considerations

Unit Sizes

General

Basic Controls Usage

Unit Nominal Capacity Tons

Accessory Navigator Display Module

Scrolling Marquee Display Menu Structure

Mode RUN Service Temperatures

SET Inputs Outputs Configuration Time Operating Alarms

Test

Run Status Mode and Sub-Mode Directory

Strt

SUB-MODE Keypad Display SUB-ITEM Comment Entry Expansion

Vers

Outs

Service Test Mode and Sub-Mode Directory

SUB-MODE Keypad Display Comment Entry Expansion Test

Cmpa

Pressure Mode and Sub-Mode Directory

Temperature Mode and Sub-Mode Directory

Set Points Mode and Sub-Mode Directory

Inputs Mode and Sub-Mode Directory

Outputs Mode and Sub-Mode Directory

Configuration Mode and Sub-Mode Directory

SUB-MODE Keypad Display Comment Entry Expansion EXV

OPT1

SUB-MODE Keypad Display Comment Entry Expansion Unit

SUB-MODE Keypad Display Comment

OPT2

XXX

XXX.X ΔF

Date

Time Clock Mode and Sub-Mode Directory

DST

Operating Mode and Sub-Mode Directory

Alarms Mode and Sub-Mode Directory

Mode Item Expansion Description

Operating Modes

Control Module Communication

Controls

Carrier Comfort Network CCN Interface

Status Inputs

CCN Communication Bus Wiring

Thermistor Designations

Output Relays

CCB

Almr

AUX

CHC

A30-4962

A30-4963

A30-4964

Typical Control Box for 30RAP035-060

Typical Wiring Schematic, 30RAP018-030 Units Power Wiring

Typical Wiring Schematic, 30RAP018-030 Units Control Wiring

A30-4966

Typical Wiring Schematic, 30RAP035-060 Units Power Wiring

5283

Typical Wiring Schematic, 30RAP035-060 Units Control Wiring

A30-5284

A30-4967

A30-4968

Page

CEPL130351

Deadband Multiplier

30RAP Unit Size Control Capacity Steps Capacity %

A30-4969

Operating Envelope for R-410A Compressor

A30-4970

Cooling Set Point Select

30RAP Unit Size FAN Stages

Control Occupancy Cooling SET Point Select Clsp Type State

Optional Factory-Installed Hydronic Pack

Control Methods and Cooling Set Points

CCN

→PM1E = YES

Configuring and Operating Dual Chiller Con

Dual Chiller Configuration Master Chiller Example

Rset

Number

Part

SUB-MODE Keypad Entry Display Item Expansion Comments

Dual Chiller Configuration Slave Chiller Example

Rset Slave Complete

To 20 mA Reset

Menu Configuration of 4 to 20 mA Cooling Set Point Control

Mode Keypad SUB Display

Configuring Outdoor Air and Space Temperature Reset

Configuring Return Temperature Reset

RED LED Entry Mode

Outdoor-Air Temperature Reset

To 20-mA Demand Limiting

PRE-START-UP

Configuring Demand Limit

Item Expansion Comment Entry Configuration

System Check

A30-4978

START-UP and Operation

30RAP Minimum Cooler Flow Maximum Cooler Flow Size

Operation Sequence

Temperature Limits for Standard 30RAP Units

Operating Limitations

Unit Size 30RA

EXV Steps

Service

Electronic Components

Unit Size 30RAP EXV Steps

A30-4971

Electronic Expansion Valve Details

Cooler

Compressor Replacement Refer to Fig

Unit Torque Specification

A30-4972

Oil Charge

Check Refrigerant Feed Components

A30-4974

A30-4973

LWT

Check Unit Safeties

Factory Settings, High-Pressure Switch Fixed

Unit Cutout CUT-IN

Thermistor Well

Temp Voltage Resistance Drop

100,260

143

86K Thermistor vs Resistance DTT

Drop

A30-4976

A30-4975

A30-499

Accsy

P50 Fault History Last 8 faults P51 Software version

TB1-TB2

Mode Nominal Voltage Control Input Start Jumper

A30-4977

TB13A-TB2

Fault Codes

Motormaster V Program Parameters for Operating Modes

Parameters Description Mode

PID

Replacement Modules

Maintenance

Replacement Replacement Part Module

Troubleshooting

Advanced Scroll Temperature Protection Label

30RAP Unit Cutout CUT-IN Size

Troubleshooting

Symptoms Cause Remedy

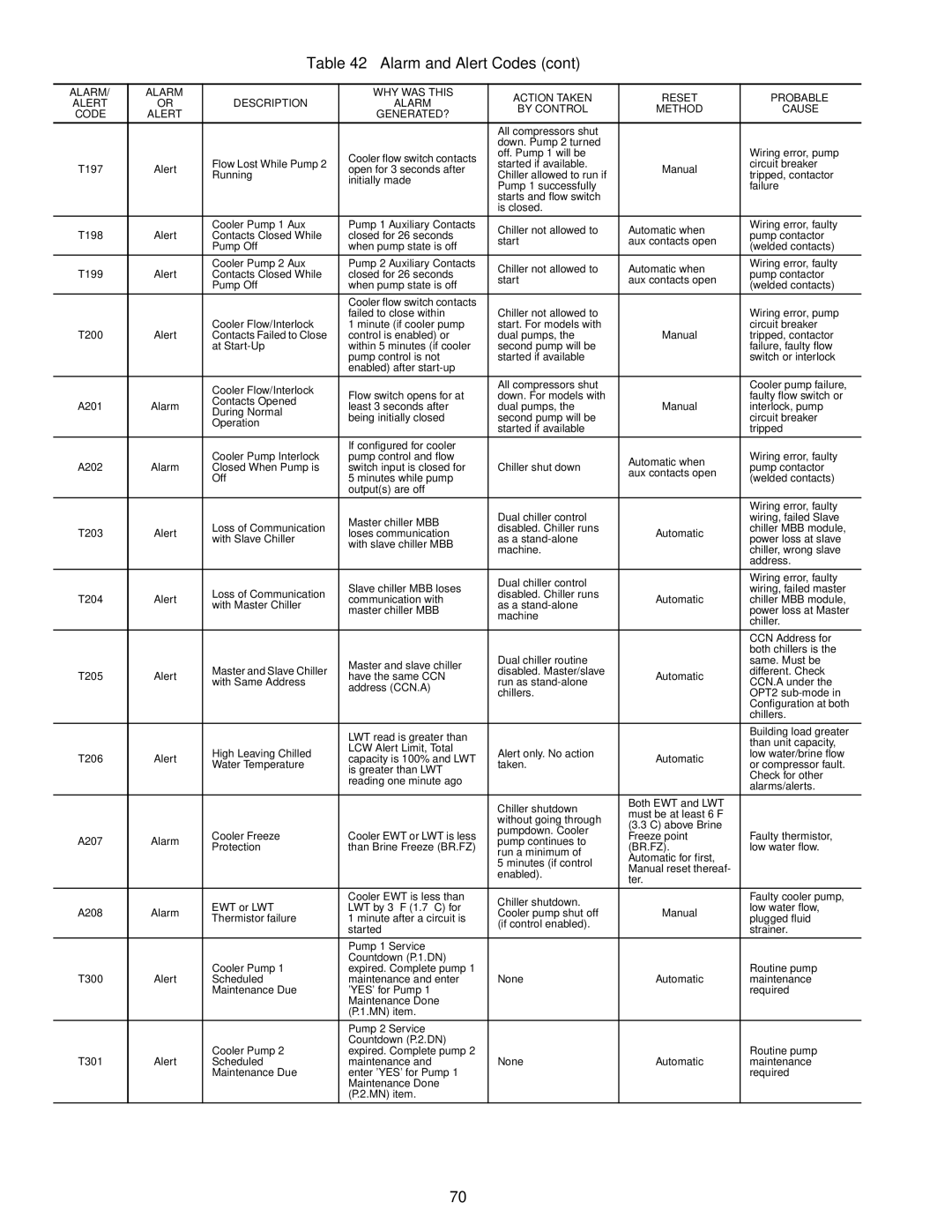

Alarm and Alert Codes

T051

T110

T153

T197

CSB

Alert GENERATED?

CCN

EMM

Compressor Stuck on Failure Alarms

Page

View

Appendix a Display Tables

SUB-MODE Display Item Description Comment

RUN

Strt

Appendix a Display Tables

Vers

Pressures Mode and Sub-Mode Directory

Head

SUB-MODE Display Item Description Range Comment

Cool

FRZ

GEN.O

SUB-MODE Display Item Description Comment

HP.A

HP.B

EXV.A

EXV.B

Rset

Bcst

DST

SUB-MODE Display Item Description Comment Time

Date

HOL.L

HD.19

HD.30

PER.1

SUB-MODE Display Item Description Comment SCH.N

SCH.L

PER.2

PER.7

PER.6

PER.8

Rcrn

Crnt

Hist

CCN Display Tables Circaan Circuit a Analog Parameters

Appendix B CCN Tables

CCN Display Tables Aunit General Unit Parameters

Description Value Units Point Name Forcible

Appendix B CCN Tables

CCN Display Tables Circban Circuit B Analog Parameters

Description Value Default Units Point Name

CCN Configuration Tables Unit Unit Configuration

CCN Configuration Tables OPTIONS1 Options 1 Configuration

CCN Display Tables Options Unit Parameters

CCN Configuration Tables OPTIONS2 Options 2 Configuration

CCN Configuration Tables Schedovr Timed Override Setup

CCN Configuration Tables Display Marquee Display Setup

CCN Configuration Tables Mmconf Motormaster Configuration

CCN Service Tables Service

Description Value Units Point Name

Description Value Point Name

CCN Maintenance Tables Alarms

Description Version Value

CCN Maintenance Tables PM-PUMP

CCN Maintenance Tables Runtest

CCN Maintenance Tables Dualchil

Appendix C Factory Settings for Pump and Manual Starters

Setting

Appendix D Optional Bacnet Communications Wiring

Optional BACnet Communications Wiring

Table B Baud Selection Table

Appendix D Optional Bacnet Communications Wiring

Table a SW3 Protocol Switch Settings For MS/TP

DS8 DS7 DS6 DS5 DS4 DS3

AWG

Table C MS/TP Wiring Recommendations

Specification Recommmendation

CL2P

Rmcorp

Wiring Specifications Recommended Vendors and Part Numbers

CMP

RUN LED Error LED Status

Table E LED Status Indicators

LED Status

Control Mode

Table G Network Points List

108

109

Weekly

Appendix E Maintenance Summary and LOG Sheets

30RAP Maintenance Interval Requirements

Quarterly

Appendix E Maintenance Summary and LOG Sheets

30RAP Weekly Maintenance Log

Unit Section Action Entry

30RAP Monthly Maintenance Log

PSI

30RAP Seasonal Shutdown Log

113

Copyright 2010 Carrier Corporation

II. Preliminary Equipment Check

START-UP Checklist for 30RAP Liquid Chiller

Remove and use for Job File Project Information

Design Information

III. Unit Start-Up

Start and Operate Machine. Complete the Following

Dual Chiller Control Only

Mode RUN Status

Record Software Versions

Submode Item Expansion Display Entry

Unit Configuration Settings

OPTIONS1 Options Configuration

OPT1

HP.A Head Pressure Cmp. Delta Configuration

OPTIONS2 Options Configuration

CCN CCN Network Configuration

HP.B Head Pressure Cmp. Delta Configuration

MM Motormaster Configuration Settings

EXV.A Circuit a EXV Configuration

EXV.B Circuit B EXV Configuration

EXV.B

Rset Reset Configuration Settings

Slct Setpoint and Ramp Load Configuration

Setpoint

SUB-MODE Keypad Display Comment

Entry Expansion