IB-106-340 Rev April

Oxymitter

Essential Instructions

Single Probe Autocalibration Sequencer information

Highlights of Changes

Effective May, 1998 Rev

Summary

Effective Oct., 1998 Rev

Changed Figure and Index No

Assemblies to parts list

Effective Feb., 1999 Rev PageSummary

Effective April, 2001 Rev

Changed Heater Fault 6 Self-Clearing column data to no

Fault 8 Self Clearing column data to YES

Effective Nov., 1999 Rev

Oxymitter

Table of Contents

Index

10-0

10-1

11-0

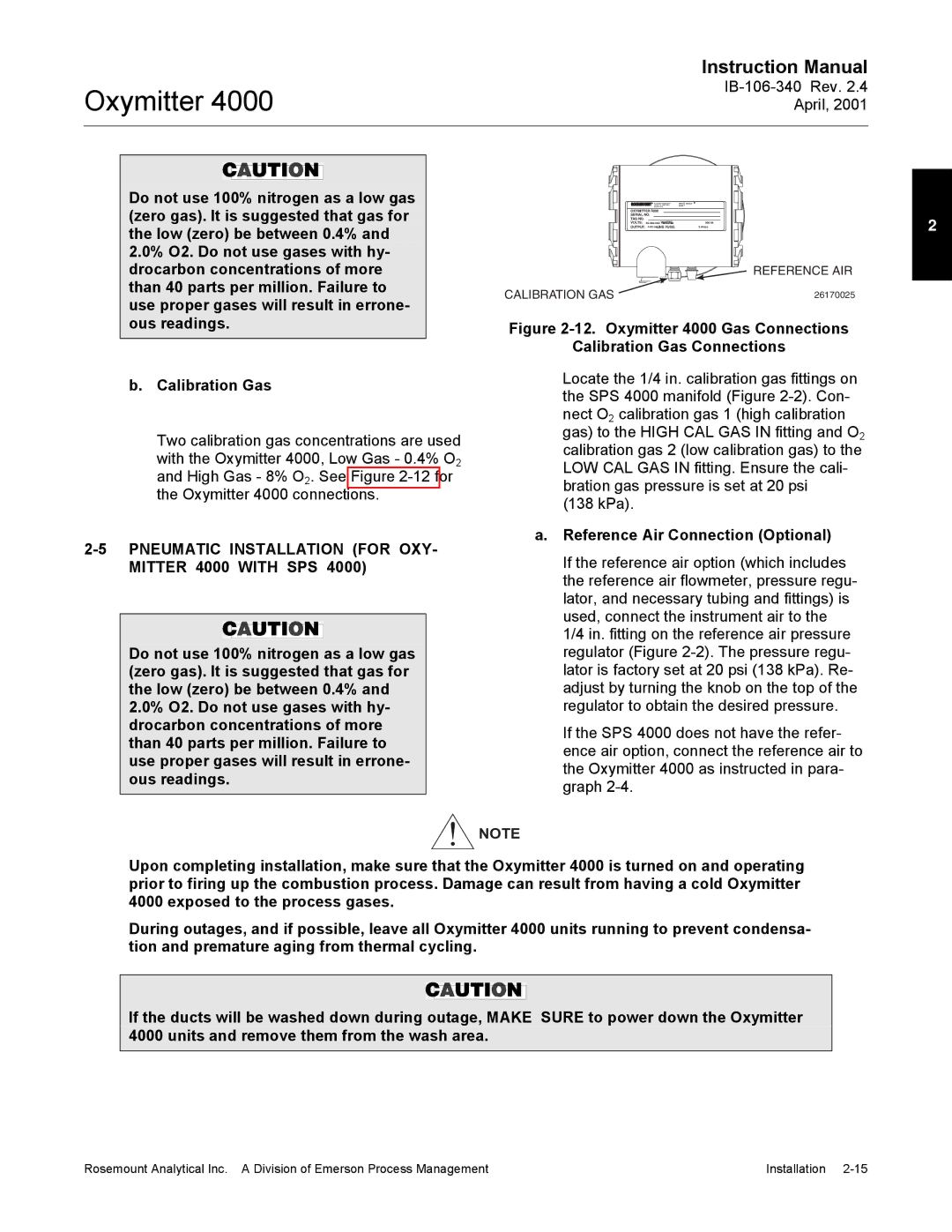

Oxymitter 4000 Gas Connections Calibration Gas Connections

List of Illustrations

List of Tables

Definitions

Preface

Oxymitter

Section I. Identification

Section II. Physical Data

Section V. Health Hazard Data

Section VI. Reactivity Data

Section VII. Spill or Leak Procedures

Section IX. Special Precautions

Oxymitter

What YOU Need to Know

Oxymitter 4000 Installation Options

Use this Quick Start Guide if

Can YOU USE the Following Quick Start GUIDE?

Quick Start Guide For Oxymitter 4000 Systems

Oxymitter 4000 with SPS 4000 Wiring Diagram

Performing a Manual Calibration

Quick Reference Guide Oxymitter 4000 Oxygen Transmitter

Technical Support Hotline

Hart Communicator Fast KEY Sequences

Oxymitter

Component Checklist of Typical System Package Contents

Section Description and Specifications

System Overview

Typical System Package

Imps

System Configuration System Features

Oxymitter Integrally Mounted

SPS

Oxymitter

Oxymitter 4000 Hart Communications and AMS Application

With Reference AIR Option

Standard

Imps 4000 Option

SPS 4000 Option

Components Figure

Imps 4000 Optional

SPS 4000 Optional

Mounting

Rear View of Manifold only

Front View

Operation

Refer to Model 751 remote powered loop LCD

Manual for calibration and wiring

Model 751 Remote Powered Loop LCD Display

Oxymitter

Specifications

40to 149F -40to 65C

Integral to Oxymitter

Remote from Oxymitter

100% relative humidity

Code Sensing Probe Type

Product Matrix

Calibration Components Part NumberDescription

Code Calibration Accessories No Hardware

Ref Air Set Fittings/Tubings Mounting Brass Code Yes Teflon

Single Probe Autocalibration Sequencer Coding

Hor Vert

Weld or bolt adapter plate -5onto the duct

Section Installation

Mechanical Installation

Selecting Location

Oxymitter 4000 Installation

Vertical Mounted SPS 4000 a

Horizontal Mounted SPS 4000 a

Oxymitter 4000 with Abrasive Shield

Oxymitter 4000 Adapter Plate Dimensions

Oxymitter 4000 Adapter Plate Installation

Oxymitter 4000 Bracing Installation

Orienting the Optional Vee Deflector

All wiring must conform to local and national codes

Electrical Installation for Oxymitter 4000 Without SPS

Intelligent Multiprobe Test Gas

Connect Line Voltage

Sequencer Instruction Bulletin

Electrical Installation for OXY- Mitter 4000 with SPS

Connect Relay Output Wiring

Connect Remote Contact Input Wiring

Connect 4-20 mA Signal Wiring

10. SPS 4000 Electrical Connections

Reference Air Package

Pneumatic Installation for OXY- Mitter 4000 Without SPS

Reference Air Connection Optional

Pneumatic Installation for OXY- Mitter 4000 with SPS

Oxymitter

Startup

Verify Mechanical Installation

Verify Terminal Block Wiring

Install terminal cover 27 and secure with screws

SW2

Verify Oxymitter 4000 Configuration

Model 751. The loop-driven LCD display

Oxymitter 4000 Defaults

Mode Configuration

Alarm

Calibration Handshake Signal

Logic I/O Configuration

Calibration

Recommended Configuration

Necessary calibrations based on calendar

Days or weeks since previous calibration

Start UP Oxymitter 4000 Calibration

Power UP

Imps 4000 Connections

Operation

Model 751 Remote Powered Loop LCD Display Optional

Overview

Normal Operation

Method 1, For Load Resistance 250 Ohms

Hart Communicator Signal Line Connections

HART/AMS

Overview

Signal Line Connections, ≥ 250 Ohms Lead Resistance

OFF-LINE and ON-LINE Operations

Hart Communicator PC Connections

Logic I/O Conifgurations

Logic I/O Configuration

Menu Tree for HART/AMS on the Oxymitter 4000 Sheet 1

Menu Tree for HART/AMS on the Oxymitter 4000 Sheet 2

Menu Tree for HART/AMS on the Oxymitter 4000 Sheet 3

Complete CAL Recommended Apply GAS GAS 1 Flow

Hart Communicator Manual O2 CAL Method

From the Detailed Setup screen, select

From the Device Setup screen, select

Defining a Timed Calibration VIA Hart

Oxymitter

Calibration

Section Maintenance and Service

Oxymitter 4000 Exploded View

Key on the Oxymitter 4000 keypad

Sets display mode from 0000 to

Cator to access the O2 Calibrate

Oxymitter 4000. Press the CAL

Manual Calibration

Alarms

Diagnostic/Unit Alarms

LED Status Indicators

Nostic alarm LED will be

Flashing. The diagnostic alarm

LED

Flashes Status Fault

High mV

Oxymitter 4000 without Integrally Mounted SPS

Oxymitter 4000 REMOVAL/REPLACEMENT

Electronics Replacement

Electronic Assembly

Terminal Block Replacement Figure

Electronic Assembly Replacement Figure

Fuse Replacement Figure

Screws on the microprocessor board

Reconnect the J1 connector to the mi

Entire Probe Replacement

Electronics rotates, repeat Alignment

Heater Strut Assembly

Heater Strut Replacement

Cell Replacement

When replacing the strut, align the slot on

Oxymitter

Ceramic Diffusion Element Replacement

Replacement Procedure

This refers to the ceramic diffusion element only General

SPS 4000 Maintenance and Component Replacement

11. SPS 4000 Manifold Assembly

18 or

Board Replacement

Connect replacement board to board

Solenoid Replacement

Interface Board

Power Supply Board

Check Valve Replacement

Pressure Switch Replacement

Flowmeter Adjustments

Pressure Regulator Optional Maintenance

Flowmeter Replacement

Oxymitter

13. Calibration Gas and Reference Air Components

Oxymitter

Alarm Indications

Section Troubleshooting

Alarm Contacts

Indications

Identifying and Correcting Alarm

High mV Dependent on position 3 of SW2

Diagnostic/Unit Alarm Fault Definitions Self

Flashes Status MA Line Fault Clearing

Dependent on position 3 of SW2

Fault 1, Open Thermocouple

Fault 2, Shorted Thermocouple

Fault 3, Reversed Thermocouple

Call the factory for assistance

Fault 4, A/D Comm Error

Fault 5, Open Heater

Fault 6, High High Heater Temp

Fault 7, High Case Temp

Fault 8, Low Heater Temp

Fault 9, High Heater Temp

Fault 10, High Cell mV

Fault 11, Bad Cell

Fault 12, Eeprom Corrupt

Fault 13, Invalid Slope

Fault 14, Invalid Constant

Fault 15, Last Calibration Failed

Nance and Service

SPS 4000 Troubleshooting

SPS 4000 Fault Finding Symptom Check Remedy

16. SPS 4000 Troubleshooting Flowchart Sheet 1

Symptom no Test GAS Flow

16. SPS 4000 Troubleshooting Flowchart Sheet 2

Section Return of Material

Oxymitter

Replacement Parts for Probe

Section Replacement Parts

Figure and Index No

Part Number Description No Dust Seal

Figure and Index No Part Number Description

Probe Disassembly Kit

Replacement Parts for Electronics

Oxymitter

Replacement Parts for Calibration Components

Replacement Parts for SPS

Oxymitter

BY-PASS Packages

Section Optional Accessories

Asset Management Solutions AMS

Hart Handheld 275 Communicator

SPS 4000 Single Autocalibration Sequencer

Imps 4000 Intelligent Multiprobe Test GAS Sequencer

Oxymitter

O2 Calibration GAS Sequencer

Oxymitter

Section Index

SPS

Warranty

Oxymitter Serial no Order no