| Revision A |

2.1.6.2 Charging Section

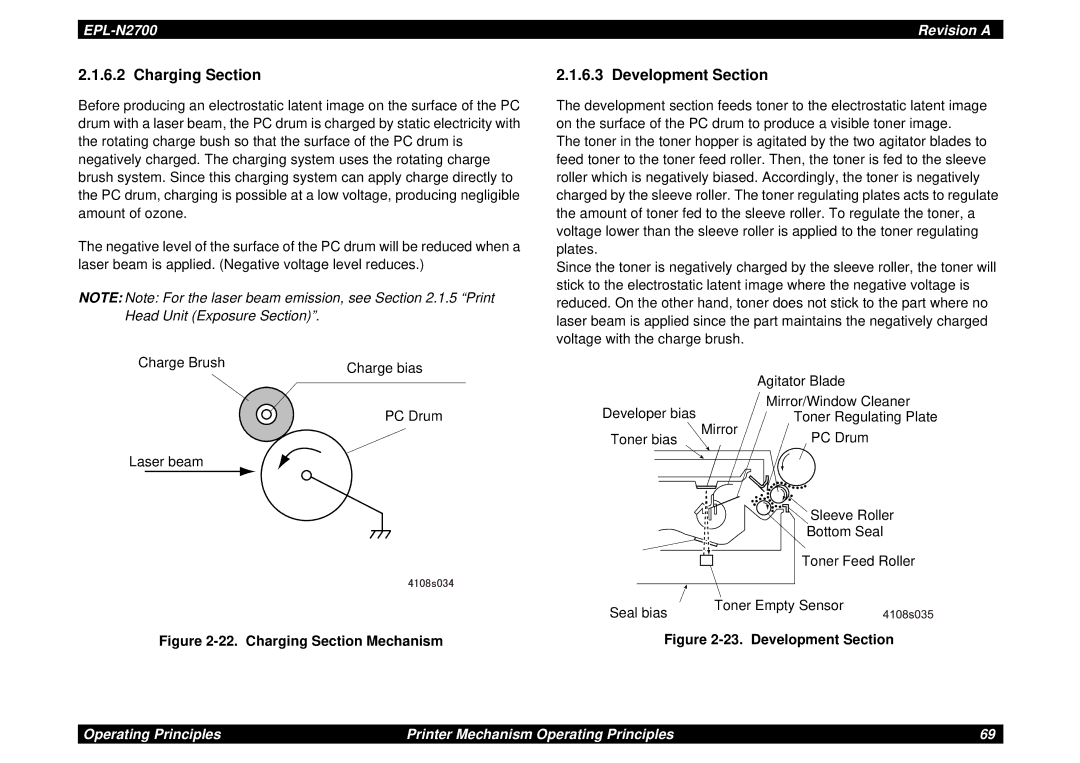

Before producing an electrostatic latent image on the surface of the PC drum with a laser beam, the PC drum is charged by static electricity with the rotating charge bush so that the surface of the PC drum is negatively charged. The charging system uses the rotating charge brush system. Since this charging system can apply charge directly to the PC drum, charging is possible at a low voltage, producing negligible amount of ozone.

The negative level of the surface of the PC drum will be reduced when a laser beam is applied. (Negative voltage level reduces.)

NOTE: Note: For the laser beam emission, see Section 2.1.5 “Print Head Unit (Exposure Section)”.

Charge Brush | Charge bias |

| |

| PC Drum |

Laser beam |

|

Figure 2-22. Charging Section Mechanism

2.1.6.3 Development Section

The development section feeds toner to the electrostatic latent image on the surface of the PC drum to produce a visible toner image.

The toner in the toner hopper is agitated by the two agitator blades to feed toner to the toner feed roller. Then, the toner is fed to the sleeve roller which is negatively biased. Accordingly, the toner is negatively charged by the sleeve roller. The toner regulating plates acts to regulate the amount of toner fed to the sleeve roller. To regulate the toner, a voltage lower than the sleeve roller is applied to the toner regulating plates.

Since the toner is negatively charged by the sleeve roller, the toner will stick to the electrostatic latent image where the negative voltage is reduced. On the other hand, toner does not stick to the part where no laser beam is applied since the part maintains the negatively charged voltage with the charge brush.

|

| Agitator Blade | |

Developer bias |

| Mirror/Window Cleaner | |

Mirror | Toner Regulating Plate | ||

Toner bias | PC Drum | ||

|

Sleeve Roller

Bottom Seal

Toner Feed Roller

Seal bias | Toner Empty Sensor |

|

Figure 2-23. Development Section

Operating Principles | Printer Mechanism Operating Principles | 69 |