IBM

Page

IBM

Fourth Edition March

Contents

Working with component and release processes

States of TeamConnection objects

Working with no component or release processes

Introduction to TeamConnection Integrated Notes Databases

Part 3. Using TeamConnection Notes Integrated Databases

Part 4. Using TeamConnection to build applications

Creating and Maintaining Integrated Notes Databases

Working with MVS build scripts and builders

Installing, starting, and stopping build servers

Working with build scripts and builders

Working with parsers Creating a parser

Part 5. Using TeamConnection to package products

Appendix J. Sample Rexx execs, build scripts, and parsers

Appendix G. Source Code Control Users Guide

Appendix H. Supported expandable keywords

Readers Comments Ð Wed Like to Hear from You

Users Guide

Figures

Xii Users Guide

Xiii

Xiv Users Guide

Trademarks

Xvi Users Guide

Conventions

About this book

How this book is organized

Xvii

Tell us what you think

Part 1. Introducing TeamConnection

Users Guide

An introduction to TeamConnection

TeamConnection denitions

TeamConnections client/server architecture

TeamConnection database

Interfaces

Parts

Families

Users and host lists

Check

Components

Check out

Releases

Work areas

Drivers

Defects and features

Processes

Build

Approval

Packaging

System administrator

Family administrator

Roles people play

Build administrator

End user

Users Guide

Part 2. Developing a product using TeamConnection

Working with component and release processes

Using the GUI

Getting familiar with the TeamConnection client interfaces

Starting the GUI

Tasks window

Stopping the GUI

Performing tasks with the GUI

Using the Settings notebook

On the GUI

Using the command line interface

Online help information

Using the TeamConnection web client

Getting familiar with the TeamConnection client interfaces

Users Guide

Basics of using TeamConnection

Laying the groundwork

Authority to perform tasks

Components window

Finding objects within TeamConnection

Finding parts

PartFull

Using work areas

BuildView

Naming your work areas

Creating parts

Naming your parts

Preparing to build your parts

Dependent

Working in serial or concurrent development mode

Working with parts

Working with common parts

Getting parts from TeamConnection

Your workstations current working directory

Checking parts in to TeamConnection

Finding different versions of TeamConnection objects

Versioning releases

Versioning work areas

Versioning drivers

Designing the resolution

Working with defects and features

Analyzing defects and features

Versioning parts

Verifying the resolution of the defect or feature

Testing and verifying part changes

Resolving defects and implementing features

Reviewing the design and resource estimates

Users Guide

Release subprocesses

States of TeamConnection objects

Component subprocesses

Open state

Design state

Canceled state

Returned state

Size state

Verify state

Review state

Working state

Closed state

Fix state

States of work areas

Approve state

Integrate state

Commit state

States of drivers

Restrict state

Test state

Restrict state

Verication and test records

Users Guide

Working with no component or release processes

Working in serial development

Accepting a defect

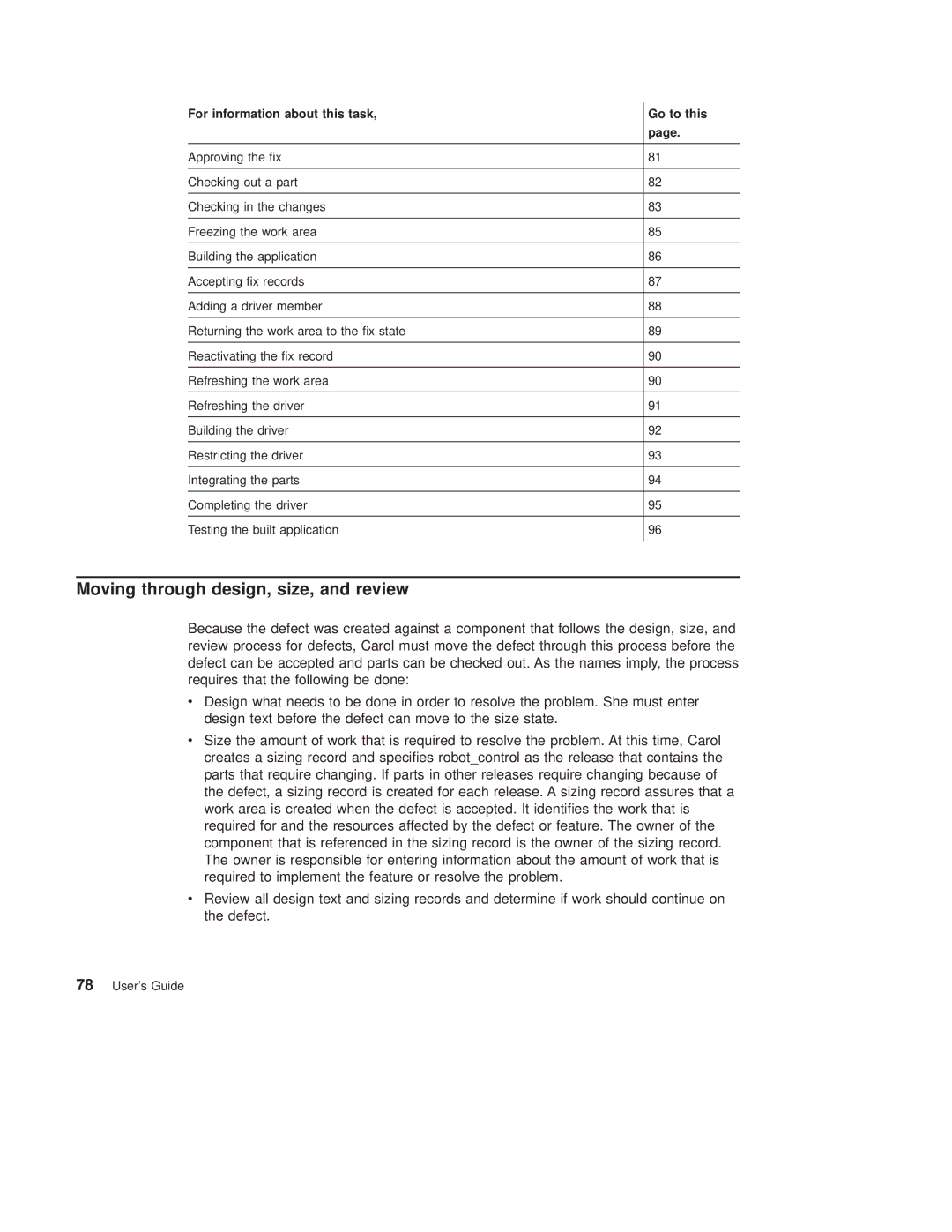

For information about this task Go to this

Result

Command

Creating a work area

Checking out a part

Create Work Areas window

Searching for a part

Check Out Parts window

Selects Save to Task List

Part Filter window

Edit Task List window

Checking in a part

Teamc part -checkin optics.c -release robotcontrol -workarea

Verifying and testing part updates

Thus, work area 310 contains the following parts

Build Parts window

Extracting a part

Extract Parts window

Checking out the part one more time

Check Out Parts

Checking the part back

Freezing the work area

Now the work area contains the following parts

Refreshing the work area

Building the application

Refresh Work Areas window

Integrating the work area

Closing a defect

Integrate Work Areas window

Working in concurrent development

Verify Defects window

Refreshing the work area from the driver

Following tasks are required

From a command line, she issues the following command

Reconciling differences

GUI

Reconcile Collision Record window

Result

Working with component and release processes

Moving through design, size, and review

Changing defect ownership

Results

Accepting a defect

Approving

\robot\src in the Destination directory eld

Accept Approval Records window

Checking in the changes

\robot\src in the Source directory eld

Now the work area contains the following part versions

Teamc workarea -freeze 456 -release robotcontrol

Building the application

Accepting x records

Complete Fix Records window

Integrating changed parts into a release

Adding a driver member

Reconciling the differences

Returning the work area to the x state

Reactivating the x record

Activate Fix Records window

Refreshing the driver

Building the driver

Refresh Drivers window

Restricting the driver

Integrating the parts

Restrict Drivers window

Completing the driver

Complete Drivers window

Testing the built application

Accept Test Records window

Using a congured process

Retrieving a past version of a part

Teamc workarea -freeze 1208 -release robotcontrol

Working with component and release processes

TeamConnection system returns the following report

Part 3. Using TeamConnection Notes Integrated Databases

101

Users Guide

103

Introduction to TeamConnection Integrated Notes Databases

Getting started

Sources of user information

Using TeamConnection with Lotus Notes

Prerequisites and dependencies

Database types

Generic

Forms and subforms

Test Case Management and Tracking

User Dened

Views

Requirements

All documents

Reviews

Document archiving

Users Guide

111

Important notice to administrators

Creating and Maintaining Integrated Notes Databases

Initializing the original template and creating a database

Select Access Control

Users Guide

Select Administration-Document Control

Select File-Save

Creating customized production databases

Select Administration-Document Control

Performing reconciliation

Database maintenance refreshing design from a template

From the File menu, select Database-Replace Design

Important notice to administrators

121

Rules of thumb and general advice

Database Design Strategies and Advanced Customization

Using the Customization setup facility

Database-specic Options

Modify Database Optional Information

Common Database Options

Modify the document hierarchy

Modify TeamConnection Access

Reconciliation of Notes and TeamConnection Data

Log Document Options

Activate Reconcile Defects and Features

Advanced customization

Users Guide

Basic build concepts

Part 4. Using TeamConnection to build applications

127

Working with parsers

Building an application an example

129

Basic build concepts

Physical structure of the build function

Build event

Build object model

TeamConnection part

Builder

Input parts

Parent-child relationships in a build tree

Build script

Output parts

Users Guide

Working with a build tree

Sample build object model for msgcat.exe

Build tree for the hello application

Putting the pieces together

For more information about this task Go to this

For more information about this task Go to this

Creating a build server on MVS

Installing, starting, and stopping build servers

Installing the build function

137

Cd JCL data set for load module

Creating a build server on MVS/OE

Cd data set for teamproc jcl

Starting build servers using teamcbld

Starting an MVS build server

Runpgm Exec PGM=TEAMCBLD

Starting the MVS/OE build server

Creating build startup les for non-MVS environments

Stopping the build servers

Stopping an MVS build server

Users Guide

147

Working with build scripts and builders

Creating a builder

Fromscriptfilespec -scriptname

Release

Environment

Comparison operator and RC value

Timeout

Writing a build script

Parameters

Passing parameters to a build script

As attributes of a builder

As parameters of the part -build command

As attributes of a part in the build tree

Writing a simple build script

Writing an executable le for a build script

Testing a build script

Modifying the contents of a build script

Putting a builder to work

Removing a builder from a part

Modify Part Properties window

Working with VisualAge C++ and Templates

Users Guide

159

Working with MVS build scripts and builders

Creating a builder for MVS builds

Builder

File type none Script null

Script, File type, and Source le

File type none Script fhbc

Comparison operator are as follows ± EQ or == Equals

Fhbcobm.jcl

Writing an MVS build script

Fhbmasm.jcl

Fhbmpli.jcl

File name conversions for MVS

Passing parameters to an MVS build script

TeamConnection syntax for MVS build scripts

Tcbldusr

Positional parameters

Supported JCL syntax

Exec statement

Keyword parameters

DD Statement

WELLSK.TEAMC.ERROR

Example of a build script for a C compile

Working with MVS build scripts and builders

Example of a build script for a Cobol compile

UNIT=SYSDA,SPACE=TRK,10,5

Example of a build script for a link

DCB=RECFM=FB,LRECL=80,BLKSIZE=3200

Sysmod DD TCEXT=LOAD,DISP=NEW,DELETE

Working with MVS build scripts and builders

Users Guide

175

Working with parsers

Creating a parser

Include

Create Parser window

Writing a parser command le

Putting a parser to work

Removing a parser from a part

From a command line, type the following

Building an application an example

181

Sample build tree

Starting the build servers

Mvspool

Creating builders and parsers

Creating the build tree for the application

Create Parts window

Create Parts window

Modify Part Properties window

Connect Parts window

Starting the build on the client

Build tree display

Work area

Build mode

Build target

Build pool

Detail le name

Putting the build scripts to work

Unconditional

Finishing the job and reporting the results to the user

Monitoring the progress of a build

Running a build in spite of errors

Building all parts, regardless of build times

Canceling a build

Finding out which parts will be built

More sample build trees

Dening multiple outputs from a single build event

Synchronizing the build of unrelated parts

He creates the collector part

Building an application an example

Users Guide

199

Part 5. Using TeamConnection to package products

Chapter Using TeamConnection to package a product

Chapter

Users Guide

Using TeamConnection to package a product

201

Setting up your build tree for packaging

Setting up a build tree for the gather tool

She also connects a readme le for the application

Adding the gather step to the build tree

205

Using the Gather tool

Using the teamcpak command for the Gather tool

Inputles

Command line ¯ags

String

Using the Gather tool

Syntax rules for a Gather package le

Examples of the teamcpak gather command

Writing a package le for the Gather tool

Targetroot targetrootpath

Keywords for a Gather package le

Packageformat gather

Source list of le specications

Target Targetpath

EXITPRIOR, EXITPOST, and Exitreplace String

Using exit keywords in the Data clause

Using exit keywords in the Rule clause

Using exit keywords an example

Package le looks like this

Users Guide

Using the Tivoli Software Distribution packaging tool

215

InputFile

Syntax rules for a Tivoli Software Distribution package le

Example of the teamcpak softdist command

Writing a package le for Tivoli Software Distribution

Packageformat softdist

Keywords for a Tivoli Software Distribution package le

Example

Nodes

Installpgm

Option

Sample package le

Log le

Trace facility

Profile

Using the Tivoli Software Distribution packaging tool

Exit # end of file

Part 6. Appendixes

225

Users Guide

Appendix A. Environment Variables

227

Nlspath

Tcbuildpool

Tccasesense

Tcmakeimportverbose

Tcrelease

TeamConnection dynamically set build environment variables

Setting environment variables

Appendix B. Importing makele information into TeamConnection

235

Connect le

Modied makele

Create le

Le mask

Content

Creating a rules le

Connect

Component

Appendix C. TeamConnection Merge

239

Parameter Description

241

Creating a TeamConnection-enabled Workframe project

Setting up your project options

Using your TeamConnection Workframe project

Project actions

Edit part

Part actions

View part information

Show parts

Using your project a simple scenario

245

Tcuser

Tcbecome

TC View Part Information

TC View Part Contents

TC Extract Part

TC Build Part

Users Guide

Overview of the ENVY/Manager-TeamConnection Bridge

249

Scope of this documentation

How the bridge communicates with TeamConnection

Preparing to use the ENVY/Manager-TeamConnection Bridge

Environment variables

Setting up the bridge environment

Prerequisites

Loading the ENVY/Manager-TeamConnection Bridge

Testing the ENVY/Manager-TeamConnection Bridge

Defaults

Using the ENVY/Manager-TeamConnection Bridge

Setting default properties

Locking

Context

Operations

Import

Replace existing les

Export

Exporting Envy components to TeamConnection

Storage in TeamConnection

Exporting conguration maps and applications

Exporting les

Importing Envy components from TeamConnection

Scenario assumptions

VisualAge Generator Developer

TeamConnection

Envy

Object mapping in TeamConnection

Build generation

TeamConnection build function

Making a change to a member

TeamConnection change control

TeamConnection change control

267

Appendix G. Source Code Control Users Guide

Projects vs Families

Installing the TeamConnection source code control DLL

Removing the TeamConnection Source Code Control DLL

Connecting TeamConnection to an IDE

Using TeamConnection as your source code control provider

Before you start

Integrated features

Opening a project

Check-out

Full features of TeamConnection

Check-in

Uncheck-out

Migrating project data bases

Starting a new project

Users Guide

Appendix H. Supported expandable keywords

275

Then the expanded keywords will look like

277

Associated release ApprovalReject Approval record owner

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

New test record owner, subscribers

Page

Page

Page

Users Guide

301

Appendix J. Sample Rexx execs, build scripts, and parsers

Sample Rexx execs

Script name Function Inputs

DrvrMem Lists the defect and feature members of a DriverName

Script name Function Inputs

Sample build scripts

Sample parsers

Sample package les

IBM Talklink

Customer support

307

Internet

DB2 service maintenance and technical library

309

Bibliography

IBM VisualAge TeamConnection Enterprise Server library

TeamConnection technical reports

Related publications

Glossary

Users Guide

Compare to

Glossary

313

Contrast with

Users Guide

Glossary

See also build dependent

End user. See user

HPFS. See high-performance le system

Users Guide

Pool. See build pool

Users Guide

TeamConnection superuser. See superuser

Users Guide

Index

323

Builder

Debug

GUI

Exitpost

Parts nding

Releases

Tcmakeimportrules 227, 235

Work area Automatic creation

Users Guide

Readers Comments Ð Wed Like to Hear from You

How satised are you that the information in this book is

Ibmr

Readers Comments Ð Wed Like to Hear from You

Page

Ibmr