Section TOC

Master TOC

THEORY OF OPERATION

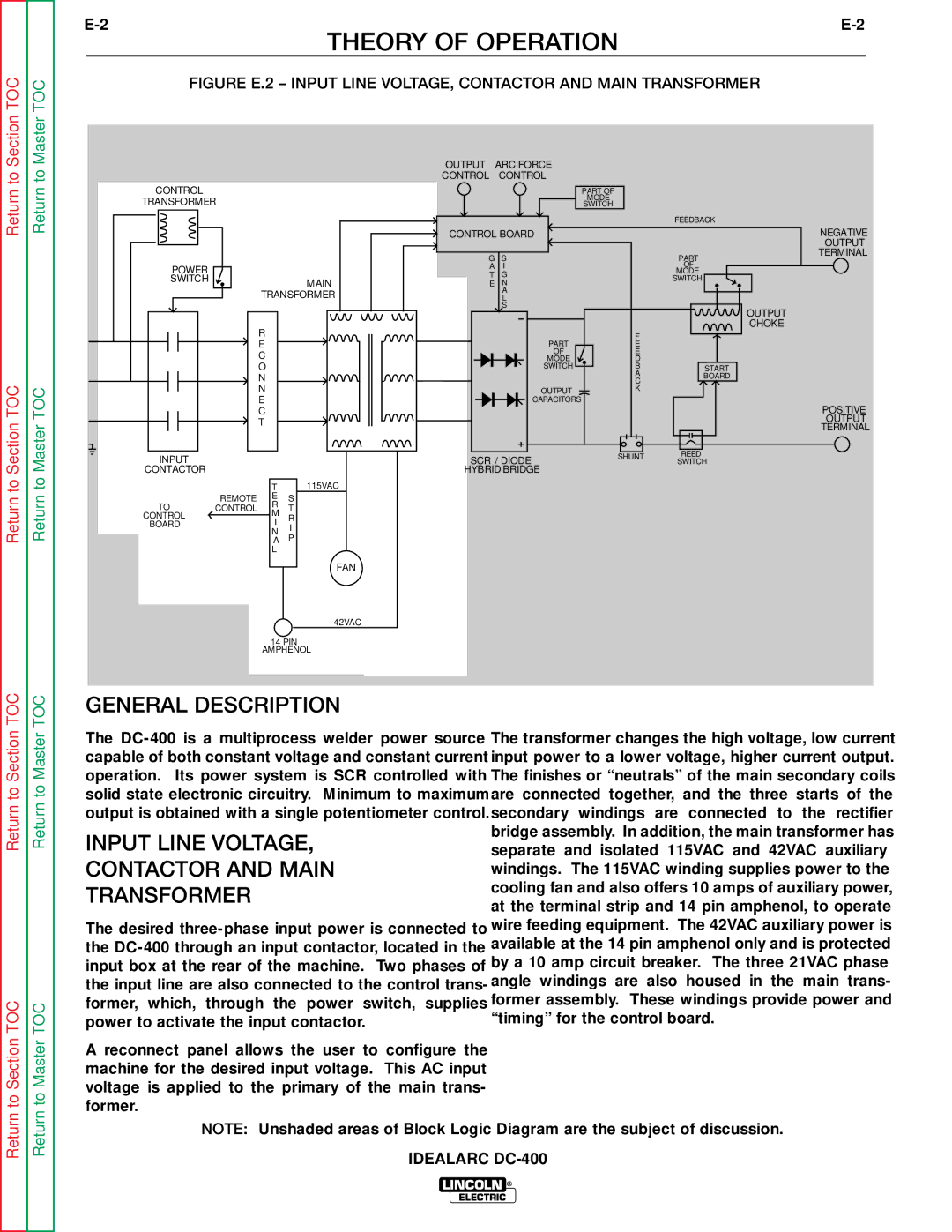

FIGURE E.2 – INPUT LINE VOLTAGE, CONTACTOR AND MAIN TRANSFORMER

Return to

Return to Section TOC

Return to

Return to Master TOC

CONTROL

TRANSFORMER

POWER |

|

|

|

SWITCH |

|

| MAIN |

|

|

| |

|

| TRANSFORMER | |

|

| R |

|

|

| E |

|

|

| C |

|

|

| O |

|

|

| N |

|

|

| N |

|

|

| E |

|

|

| C |

|

|

| T |

|

INPUT |

|

|

|

CONTACTOR |

|

|

|

|

| T | 115VAC |

| REMOTE | E | S |

TO | CONTROL | R | T |

CONTROL |

| M | R |

BOARD |

| I | I |

|

| N | |

|

| P | |

|

| A | |

|

| L |

|

|

|

| FAN |

|

|

| 42VAC |

|

| 14 PIN | |

|

| AMPHENOL | |

OUTPUT | ARC FORCE |

|

|

|

CONTROL | CONTROL |

|

|

|

| PART OF |

|

|

|

| MODE |

|

|

|

| SWITCH |

|

|

|

|

|

| FEEDBACK |

|

CONTROL BOARD |

|

| NEGATIVE | |

|

|

|

| OUTPUT |

G | S |

| PART | TERMINAL |

|

| |||

A | I |

| OF |

|

T | G |

| MODE |

|

| SWITCH |

| ||

E | N |

|

| |

|

|

| ||

| A |

|

|

|

| L |

|

|

|

| S |

|

| OUTPUT |

|

|

|

| |

|

|

|

| CHOKE |

|

| F |

|

|

| PART | E |

|

|

| OF | E |

|

|

| MODE | D |

|

|

| SWITCH | B | START |

|

|

| A | BOARD |

|

|

| C |

| |

|

|

|

| |

| OUTPUT | K |

|

|

|

|

|

| |

| CAPACITORS |

|

|

|

|

|

|

| POSITIVE |

|

|

|

| OUTPUT |

|

|

|

| TERMINAL |

SCR / DIODE | SHUNT | REED |

| |

SWITCH |

| |||

|

| |||

HYBRID BRIDGE |

|

|

| |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

GENERAL DESCRIPTION

The | The transformer changes the high voltage, low current | |

capable of both constant voltage and constant current | input power to a lower voltage, higher current output. | |

operation. Its power system is SCR controlled with | The finishes or “neutrals” of the main secondary coils | |

solid state electronic circuitry. Minimum to maximum | are connected together, and the three starts of the | |

output is obtained with a single potentiometer control. | secondary windings are connected to the rectifier | |

INPUT LINE VOLTAGE, | bridge assembly. In addition, the main transformer has | |

separate and isolated 115VAC and 42VAC auxiliary | ||

CONTACTOR AND MAIN | windings. The 115VAC winding supplies power to the | |

TRANSFORMER | cooling fan and also offers 10 amps of auxiliary power, | |

at the terminal strip and 14 pin amphenol, to operate | ||

| ||

The desired | wire feeding equipment. The 42VAC auxiliary power is | |

the | available at the 14 pin amphenol only and is protected | |

input box at the rear of the machine. Two phases of | by a 10 amp circuit breaker. The three 21VAC phase | |

the input line are also connected to the control trans- | angle windings are also housed in the main trans- | |

former, which, through the power switch, supplies | former assembly. These windings provide power and | |

power to activate the input contactor. | “timing” for the control board. |

A reconnect panel allows the user to configure the machine for the desired input voltage. This AC input voltage is applied to the primary of the main trans- former.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

IDEALARC

LINCOLN ®

ELECTRIC