Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

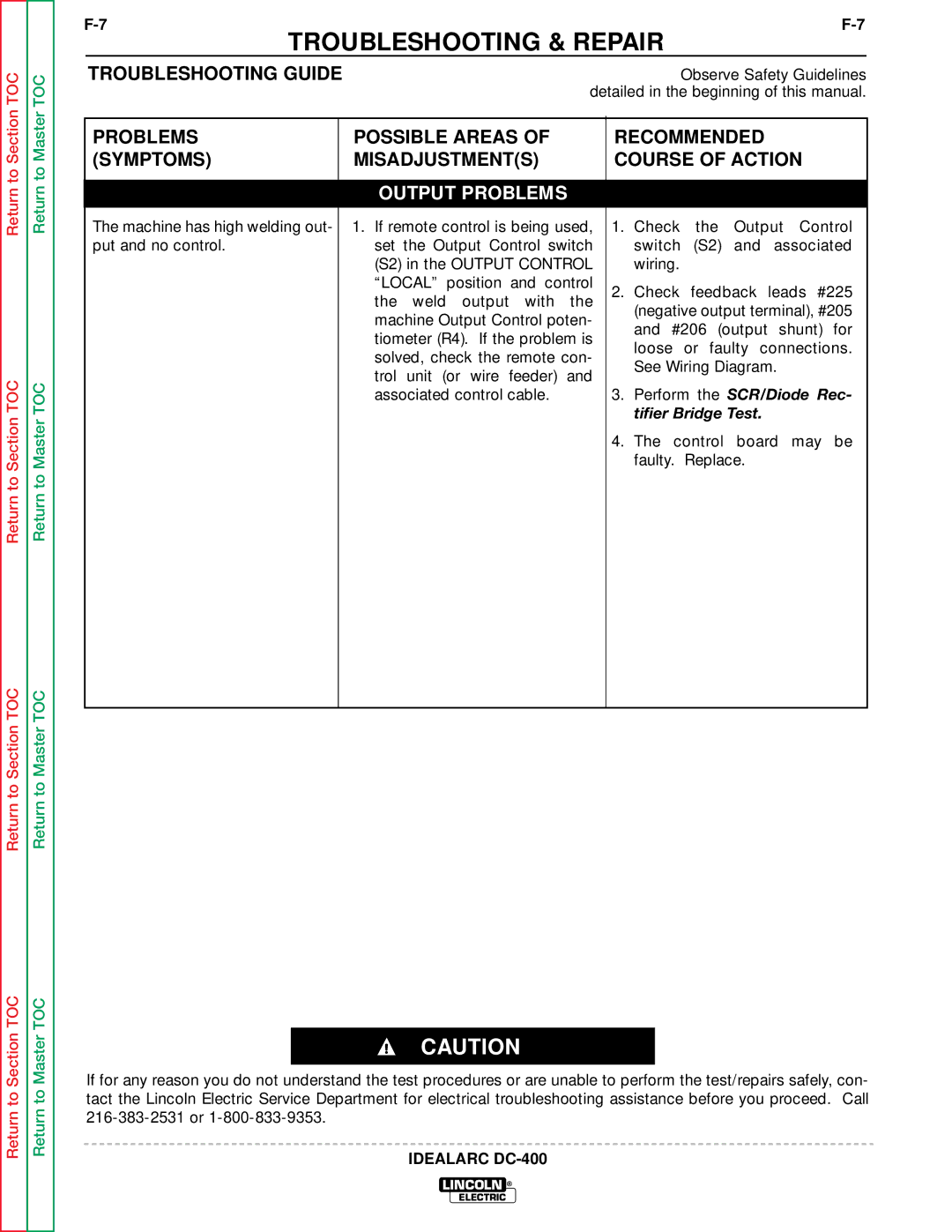

| TROUBLESHOOTING & REPAIR | |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines |

|

| detailed in the beginning of this manual. |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| ||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |||

|

|

|

|

|

|

| OUTPUT PROBLEMS |

|

|

|

|

The machine has high welding out- | 1. If remote control is being used, | 1. Check the Output Control | |||

put and no control. | set the Output Control switch | switch | (S2) and | associated | |

| (S2) in the OUTPUT CONTROL | wiring. |

|

|

|

| “LOCAL” position and control | 2. Check | feedback | leads #225 | |

| the weld output with the | ||||

| (negative output terminal), #205 | ||||

| machine Output Control poten- | ||||

| and #206 | (output | shunt) for | ||

| tiometer (R4). If the problem is | ||||

| loose | or | faulty connections. | ||

| solved, check the remote con- | ||||

| See Wiring Diagram. | ||||

| trol unit (or wire feeder) and | ||||

|

|

|

|

| |

| associated control cable. | 3. Perform the SCR/Diode Rec- | |||

|

| tifier Bridge Test. |

| ||

|

| 4. The control board may be | |||

|

| faulty. Replace. |

| ||

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

IDEALARC

LINCOLN ®

ELECTRIC