Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

| ||||

| TROUBLESHOOTING & REPAIR |

| |||

| Observe Safety Guidelines |

| TROUBLESHOOTING GUIDE | ||

| detailed in the beginning of this manual. |

|

|

| |

|

|

|

| ||

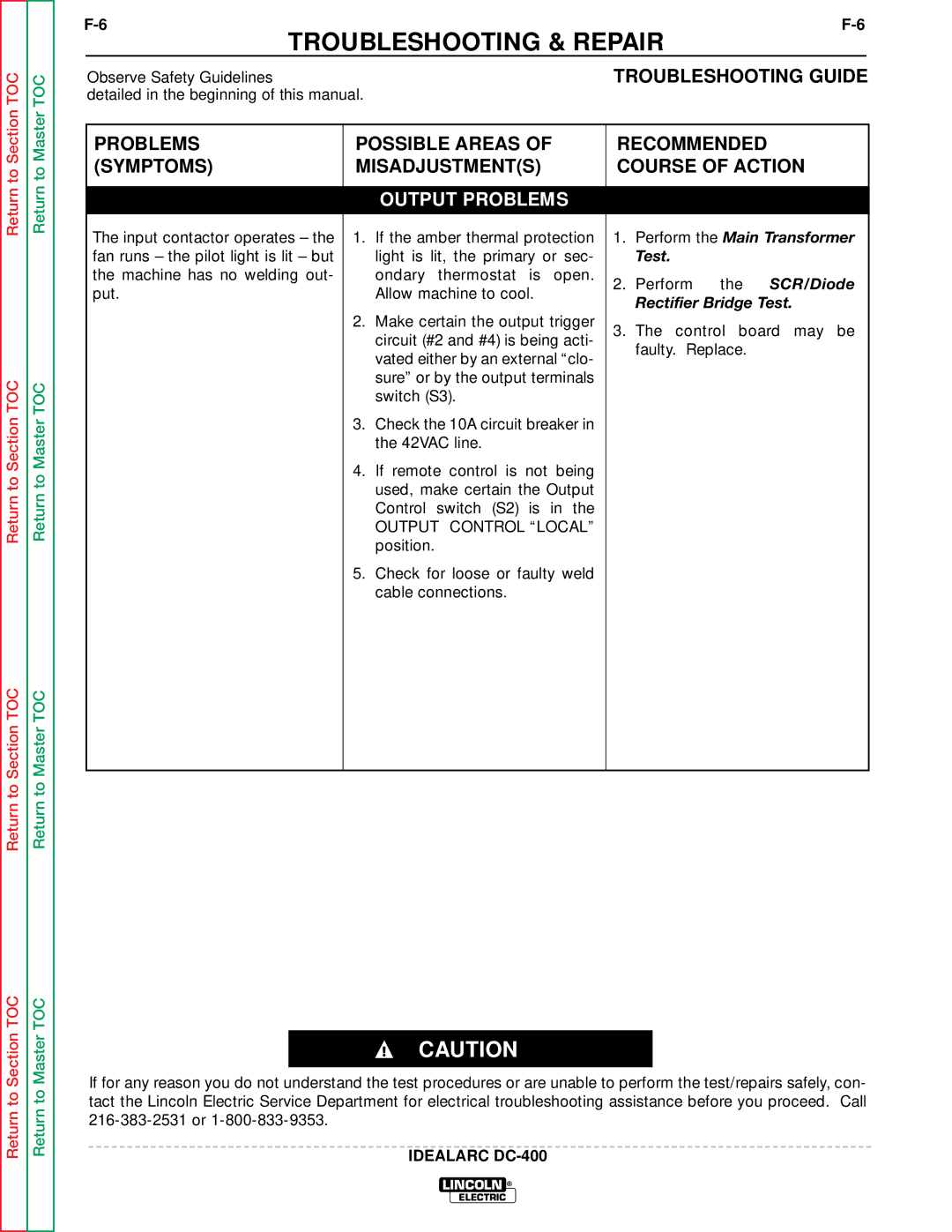

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | ||

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | ||

|

|

|

|

|

|

|

| OUTPUT PROBLEMS |

|

|

|

| The input contactor operates – the | 1. If the amber thermal protection | 1. | Perform the Main Transformer | |

| fan runs – the pilot light is lit – but | light is lit, the primary or sec- |

| Test. | |

| the machine has no welding out- | ondary thermostat is open. | 2. | Perform the SCR/Diode | |

| put. | Allow machine to cool. | |||

|

| Rectifier Bridge Test. | |||

|

|

|

| ||

|

| 2. Make certain the output trigger | 3. | The control board may be | |

|

| circuit (#2 and #4) is being acti- | |||

|

|

| faulty. Replace. | ||

|

| vated either by an external “clo- |

| ||

|

|

|

|

| |

|

| sure” or by the output terminals |

|

|

|

|

| switch (S3). |

|

|

|

|

| 3. Check the 10A circuit breaker in |

|

|

|

|

| the 42VAC line. |

|

|

|

|

| 4. If remote control is not being |

|

|

|

|

| used, make certain the Output |

|

|

|

|

| Control switch (S2) is in the |

|

|

|

|

| OUTPUT CONTROL “LOCAL” |

|

|

|

|

| position. |

|

|

|

|

| 5. Check for loose or faulty weld |

|

|

|

|

| cable connections. |

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

IDEALARC

LINCOLN ®

ELECTRIC