Section TOC

Master TOC

TROUBLESHOOTING & REPAIR

MOUNTING OF STUD TYPE DIODES TO ALUMINUM

HEAT SINKS (continued)

Return to

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1.Remove the main input supply power to the machine.

2.With the 5/16” nut driver, remove the case top and sides.

3.Loosen the appropriate diode nut and remove the diode that is to be replaced.

4.Clean the area on the heat sink around the diode mounting surface using a putty knife or similar tool. DO NOT SCRATCH THE DIODE MOUNTING SURFACE.

5.Polish each heat sink’s mounting surface using No. 000 fine steel wool. Wipe the sur- face clean with a

6.Inspect the mounting surfaces of each new diode. Remove all burrs and wipe clean. Do not use steel wool or any abrasive cleanser on the diode mounting surface.

7.Apply a thin (0.003” to 0.007”) uniform layer of E1868 (Dow Corning 340) heat sink com- pound to the heat sink mounting surface.

a.Do not apply compound to the diode stud or mounting threads.

b.The diode threads must be clean and free of defects so that the nut can be fin- ger tightened before applying torque. A “slip” type torque wrench must be used to tighten the diode nut.

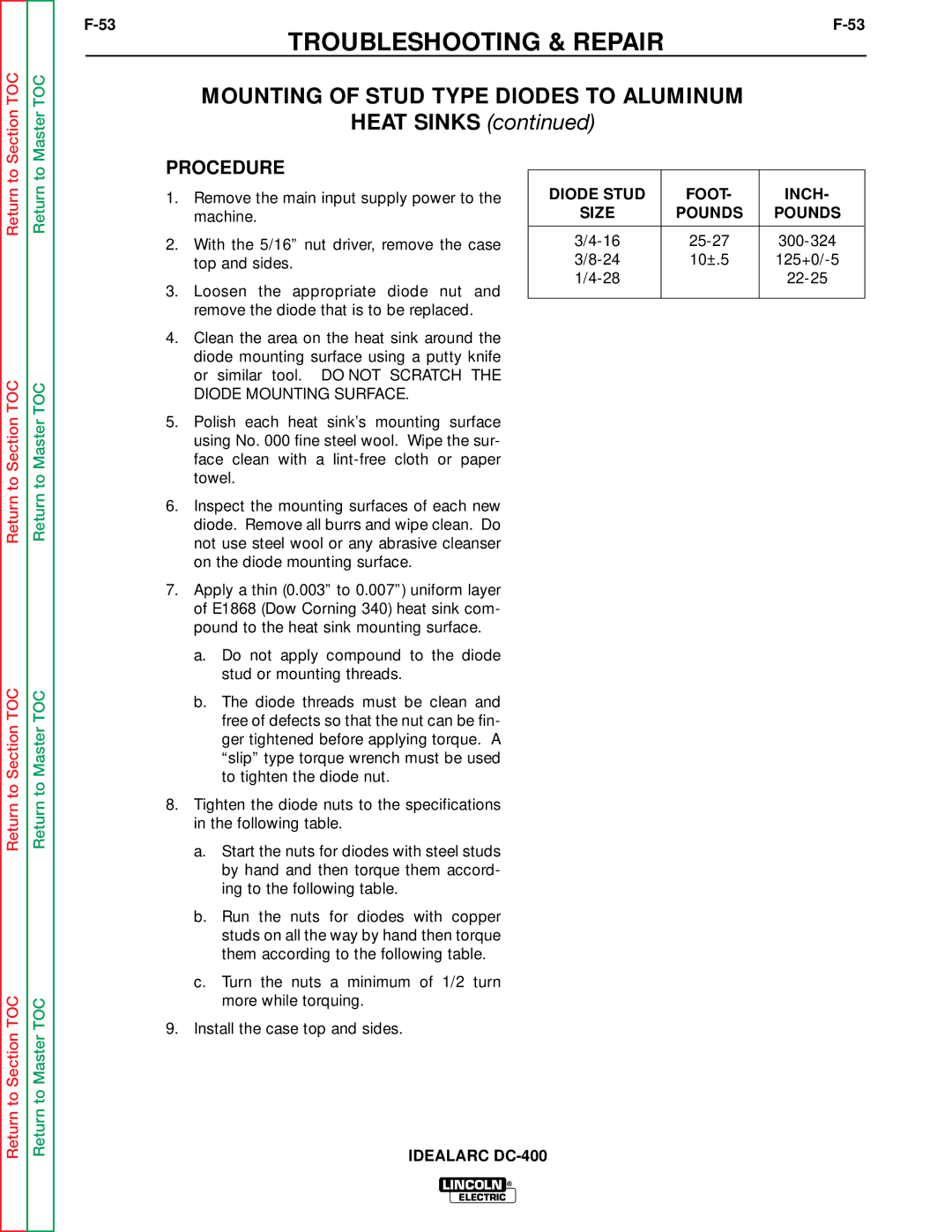

8.Tighten the diode nuts to the specifications in the following table.

a.Start the nuts for diodes with steel studs by hand and then torque them accord- ing to the following table.

b.Run the nuts for diodes with copper studs on all the way by hand then torque them according to the following table.

c.Turn the nuts a minimum of 1/2 turn more while torquing.

9.Install the case top and sides.

DIODE STUD | FOOT- | INCH- |

SIZE | POUNDS | POUNDS |

|

|

|

10±.5 | ||

| ||

|

|

|

IDEALARC

LINCOLN ®

ELECTRIC