Pressure Systems, Inc. | Model 9116 User’s Manual |

| |

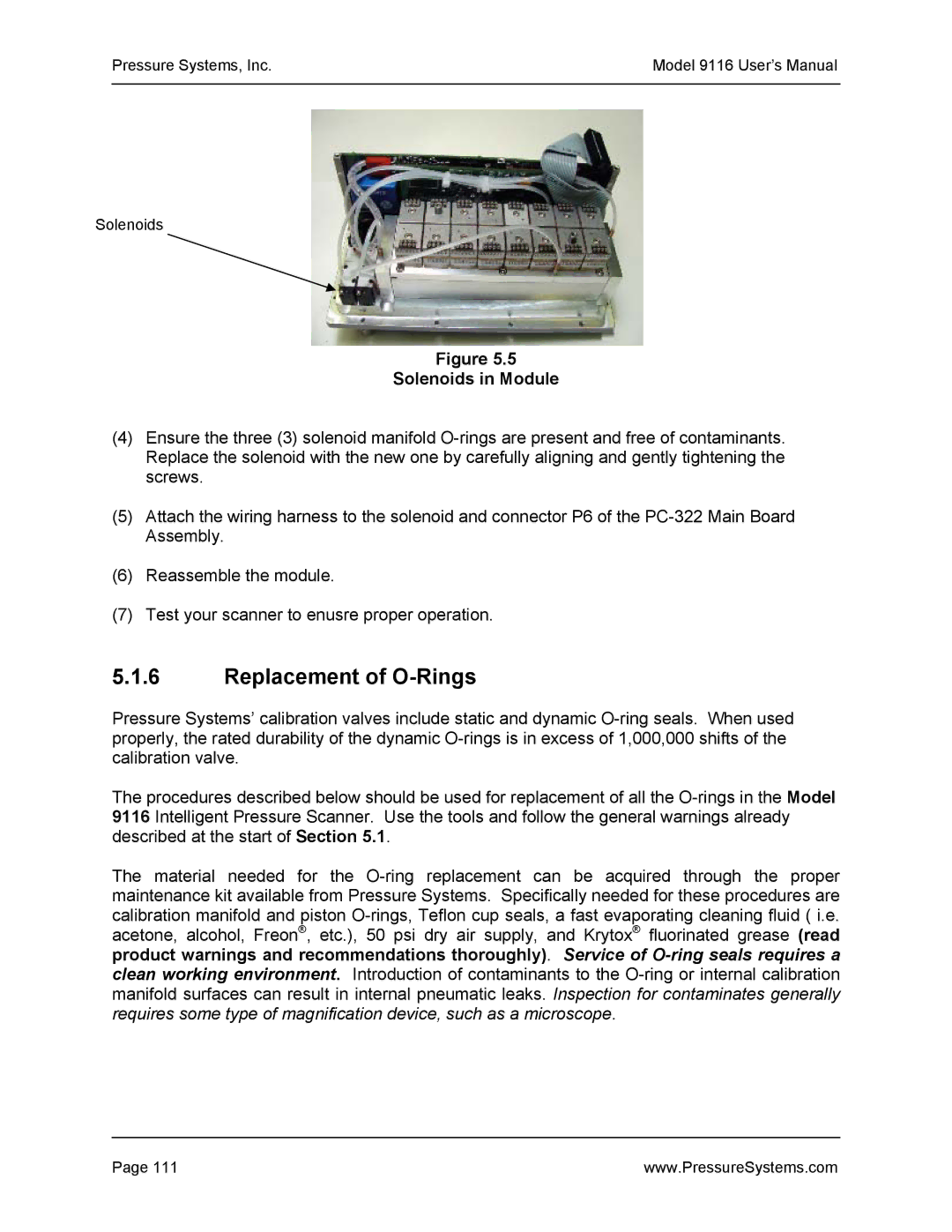

Solenoids

Figure 5.5

Solenoids in Module

(4)Ensure the three (3) solenoid manifold O-rings are present and free of contaminants. Replace the solenoid with the new one by carefully aligning and gently tightening the screws.

(5)Attach the wiring harness to the solenoid and connector P6 of the PC-322 Main Board Assembly.

(6)Reassemble the module.

(7)Test your scanner to enusre proper operation.

5.1.6Replacement of O-Rings

Pressure Systems’ calibration valves include static and dynamic O-ring seals. When used properly, the rated durability of the dynamic O-rings is in excess of 1,000,000 shifts of the calibration valve.

The procedures described below should be used for replacement of all the O-rings in the Model 9116 Intelligent Pressure Scanner. Use the tools and follow the general warnings already described at the start of Section 5.1.

The material needed for the O-ring replacement can be acquired through the proper maintenance kit available from Pressure Systems. Specifically needed for these procedures are calibration manifold and piston O-rings, Teflon cup seals, a fast evaporating cleaning fluid ( i.e. acetone, alcohol, Freon®, etc.), 50 psi dry air supply, and Krytox® fluorinated grease (read product warnings and recommendations thoroughly). Service of O-ring seals requires a clean working environment. Introduction of contaminants to the O-ring or internal calibration manifold surfaces can result in internal pneumatic leaks. Inspection for contaminates generally requires some type of magnification device, such as a microscope.

Page 111 | www.PressureSystems.com |