Chapter 4 Operation

-If the output data is sent from the host computer to the recorder while the above warning is being issued, the warning disappears, executing output operation. After output operation has been completed, the warning message appears and the buzzer sounds again.

•Handling waste liquid

Scale lines indicating capacity are marked on the waste chemical tank. Observe the scale line carefully and dispose of the processing chemical before it reaches the

When the waste chemical tank is full, the "Waste tank check" message appears and a buzzer sounds. (Images cannot be read at this time.)

Dispose of the processing chemical following the procedure below.

1)Press the ![]() key to turn off the buzzer.

key to turn off the buzzer.

2)Remove the cap from the waste chemical tank and dispose of the waste chemical in the tank.

3)Put the cap back on the now empty tank and put it back in the waste chemical vat.

-The waste chemical tank weighs approximately 11 kilograms when it is full, so please be very careful when handling it. (Refer to "1.3

Caution Handling processing chemicals".)

-Be careful when handling the hose attached to the waste chemical cap. Using a crimped or twisted hose can cause chemical leakage.

•If the machine is not used for a long period

Caution

Before deactivating the machine for a long time (7 days or more), always drain the water in the rinse water replenisher bottle.

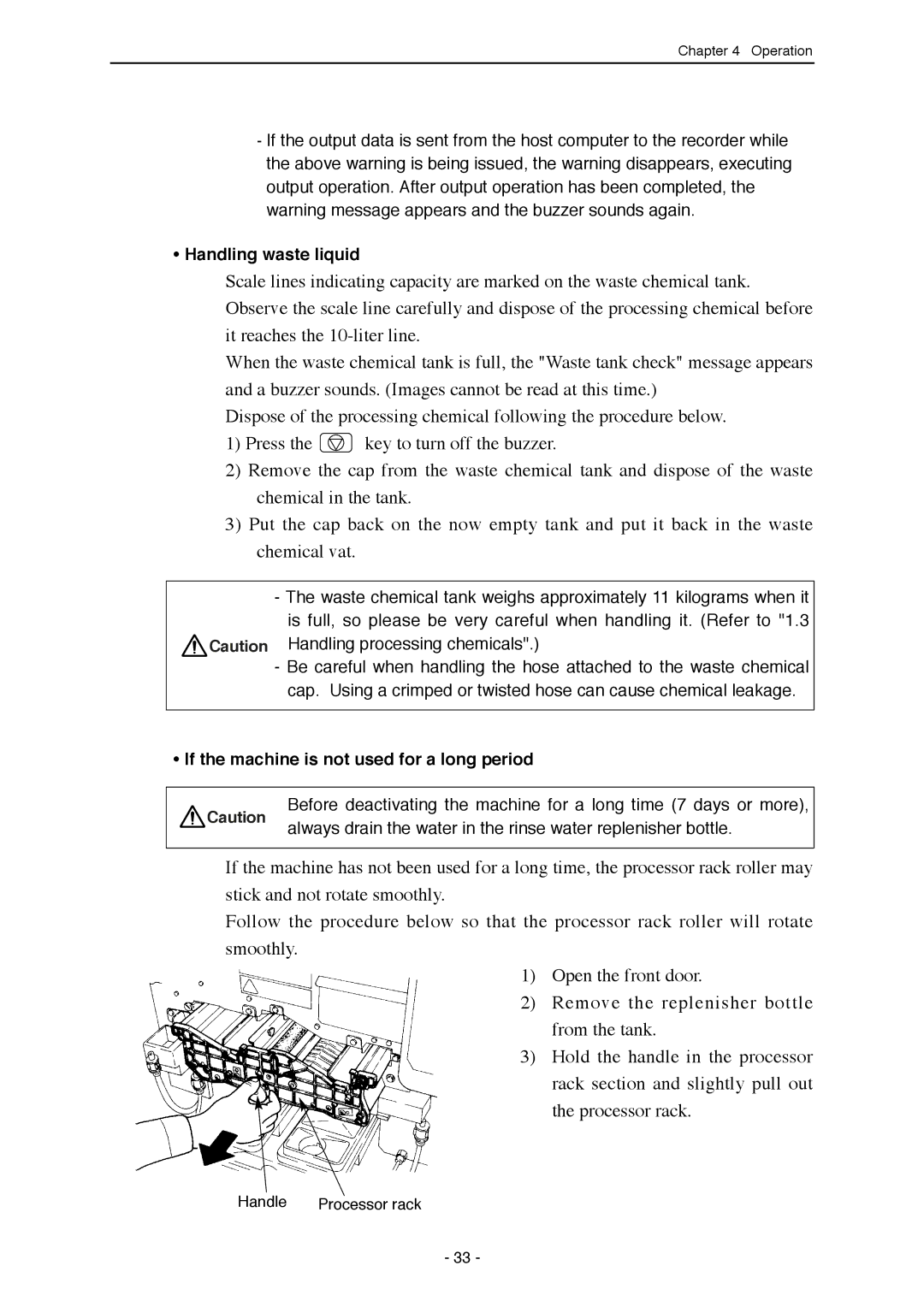

If the machine has not been used for a long time, the processor rack roller may stick and not rotate smoothly.

Follow the procedure below so that the processor rack roller will rotate smoothly.

1) Open the front door.

2) Remove the replenisher bottle from the tank.

3) Hold the handle in the processor rack section and slightly pull out the processor rack.

Handle | Processor rack |

- 33 -