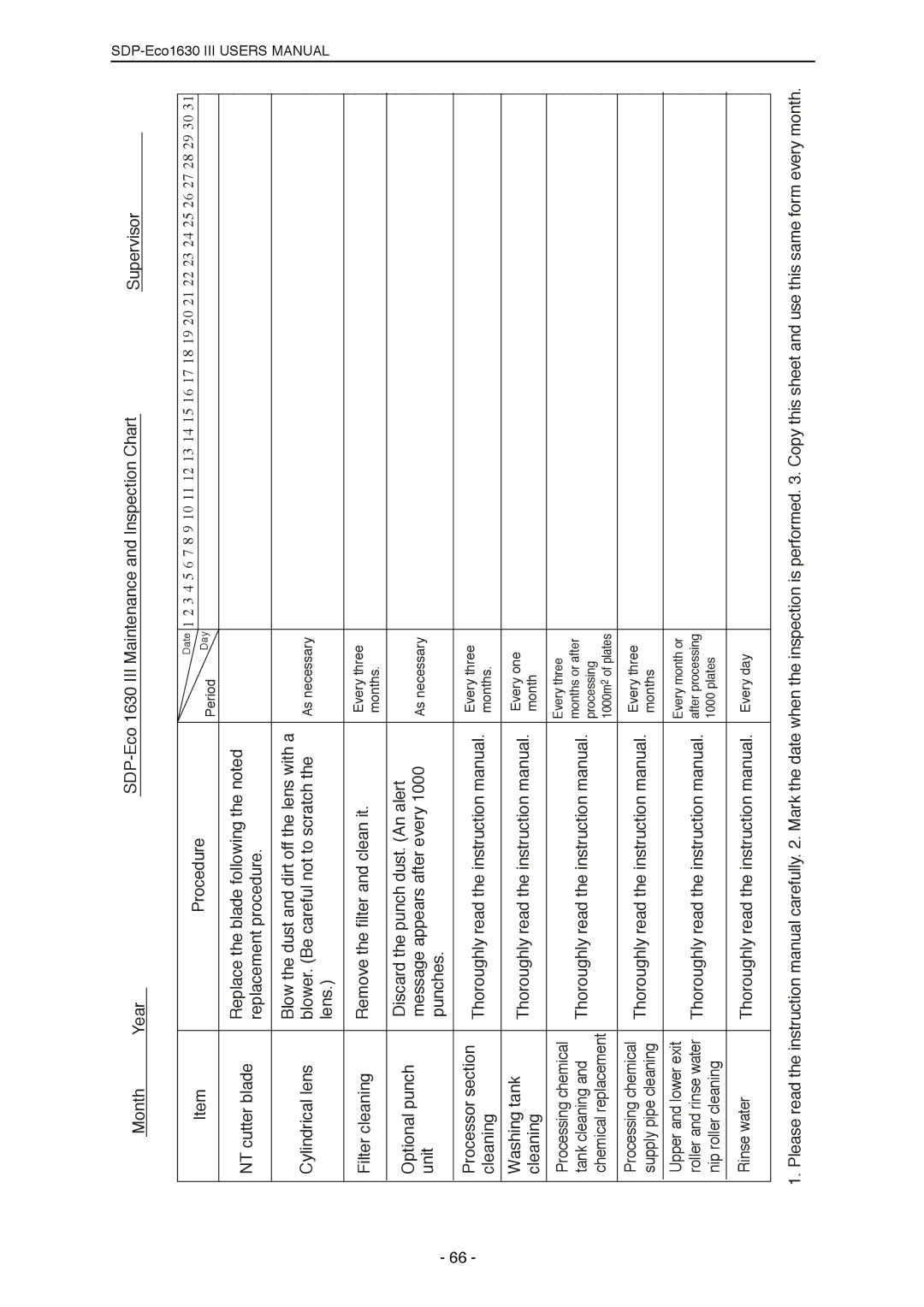

Month | Year |

| Supervisor |

|

|

ItemProcedure

Date 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Period Day

III

- 66 -

NT cutter blade

Cylindrical lens

Filter cleaning

Optional punch unit

Processor section cleaning

Washing tank cleaning

Processing chemical tank cleaning and chemical replacement

Replace the blade following the noted replacement procedure.

Blow the dust and dirt off the lens with a blower. (Be careful not to scratch the lens.)

Remove the filter and clean it.

Discard the punch dust. (An alert message appears after every 1000 punches.

Thoroughly read the instruction manual.

Thoroughly read the instruction manual.

Thoroughly read the instruction manual.

As necessary

Every three months.

As necessary

Every three months.

Every one month

Every three months or after processing 1000m2 of plates

USERS MANUAL

Processing chemical supply pipe cleaning

Upper and lower exit roller and rinse water nip roller cleaning

Rinse water

Thoroughly read the instruction manual.

Thoroughly read the instruction manual.

Thoroughly read the instruction manual.

Every three months

Every month or after processing 1000 plates

Every day

1. Please read the instruction manual carefully. 2. Mark the date when the inspection is performed. 3. Copy this sheet and use this same form every month.