4. Software Implementation of the Gateway

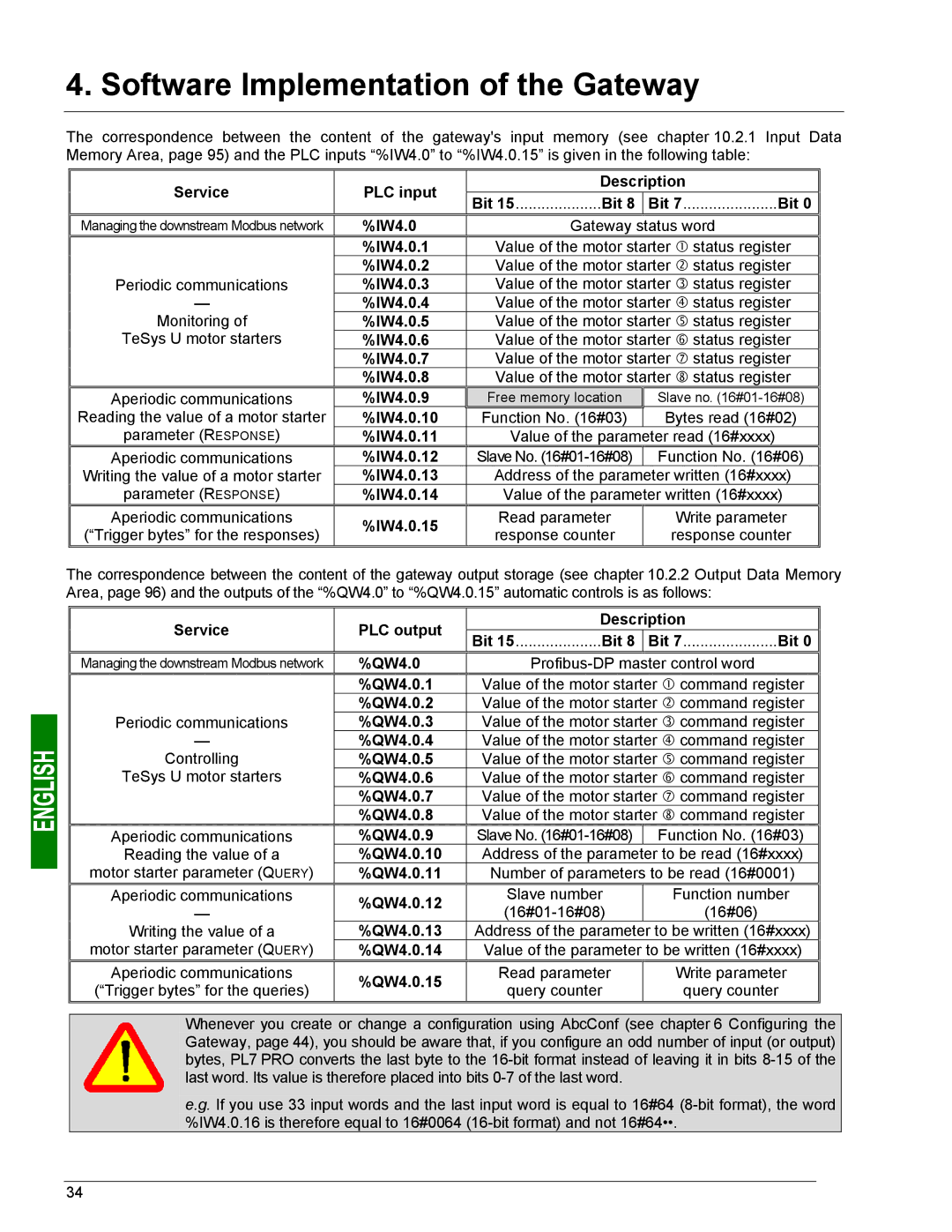

The correspondence between the content of the gateway's input memory (see chapter 10.2.1 Input Data Memory Area, page 95) and the PLC inputs “%IW4.0” to “%IW4.0.15” is given in the following table:

Service | PLC input | Description | ||

Bit 15....................Bit 8 | Bit 7......................Bit 0 | |||

|

| |||

Managing the downstream Modbus network | %IW4.0 | Gateway status word | ||

| %IW4.0.1 | Value of the motor starter c status register | ||

Periodic communications | %IW4.0.2 | Value of the motor starter d status register | ||

%IW4.0.3 | Value of the motor starter e status register | |||

— | %IW4.0.4 | Value of the motor starter f status register | ||

Monitoring of | %IW4.0.5 | Value of the motor starter g status register | ||

TeSys U motor starters | %IW4.0.6 | Value of the motor starter h status register | ||

| %IW4.0.7 | Value of the motor starter i status register | ||

| %IW4.0.8 | Value of the motor starter j status register | ||

Aperiodic communications | %IW4.0.9 | Free memory location | Slave no. | |

Reading the value of a motor starter | %IW4.0.10 | Function No. (16#03) | Bytes read (16#02) | |

parameter (RESPONSE) | %IW4.0.11 | Value of the parameter read (16#xxxx) | ||

Aperiodic communications | %IW4.0.12 | Slave No. | Function No. (16#06) | |

Writing the value of a motor starter | %IW4.0.13 | Address of the parameter written (16#xxxx) | ||

parameter (RESPONSE) | %IW4.0.14 | Value of the parameter written (16#xxxx) | ||

Aperiodic communications | %IW4.0.15 | Read parameter | Write parameter | |

(“Trigger bytes” for the responses) | response counter | response counter | ||

| ||||

The correspondence between the content of the gateway output storage (see chapter 10.2.2 Output Data Memory Area, page 96) and the outputs of the “%QW4.0” to “%QW4.0.15” automatic controls is as follows:

Service | PLC output | Description | ||

Bit 15....................Bit 8 | Bit 7......................Bit 0 | |||

|

| |||

Managing the downstream Modbus network | %QW4.0 | |||

| %QW4.0.1 | Value of the motor starter c command register | ||

Periodic communications | %QW4.0.2 | Value of the motor starter d command register | ||

%QW4.0.3 | Value of the motor starter e command register | |||

— | %QW4.0.4 | Value of the motor starter f command register | ||

Controlling | %QW4.0.5 | Value of the motor starter g command register | ||

TeSys U motor starters | %QW4.0.6 | Value of the motor starter h command register | ||

| %QW4.0.7 | Value of the motor starter i command register | ||

| %QW4.0.8 | Value of the motor starter j command register | ||

Aperiodic communications | %QW4.0.9 | Slave No. | Function No. (16#03) | |

Reading the value of a | %QW4.0.10 | Address of the parameter | to be read (16#xxxx) | |

motor starter parameter (QUERY) | %QW4.0.11 | Number of parameters to be read (16#0001) | ||

Aperiodic communications | %QW4.0.12 | Slave number | Function number | |

— | (16#06) | |||

| ||||

Writing the value of a | %QW4.0.13 | Address of the parameter | to be written (16#xxxx) | |

motor starter parameter (QUERY) | %QW4.0.14 | Value of the parameter to be written (16#xxxx) | ||

Aperiodic communications | %QW4.0.15 | Read parameter | Write parameter | |

(“Trigger bytes” for the queries) | query counter | query counter | ||

| ||||

Whenever you create or change a configuration using AbcConf (see chapter 6 Configuring the Gateway, page 44), you should be aware that, if you configure an odd number of input (or output) bytes, PL7 PRO converts the last byte to the

e.g. If you use 33 input words and the last input word is equal to 16#64

34