AIR-CONDITIONER

Contents

104

10-1

10-2

11-1

Confirmation of warning label on the main unit

Explanation of indications

Explanation of illustrated marks

Indication Explanation

Catch the inner wires

∗ For details, refer to the parts list

Never recover the refrigerant into the outdoor unit

Do not modify the products

Side

Check the following items after reinstallation

Metal section Earth position

Limit even if the refrigerant leaks

Copper pipe Piping

Safety Caution Concerned to New Refrigerant

Pipe Materials

Flare nut

R410A Conventional air

Air conditioner installation Conditioner installation

General tools Conventional tools can be used

Used tool Usage

Single type

Indoor Unit

Way Air Discharge Cassette Type

Model Indoor unit

RAV SM564UT-E SM804UT-E

SM1104UT-E SM1404UT-E Outdoor unit

Twin type

SP1104ATZZG-E SP1404ATZZG-E

SM1103AT-E SM1403AT-E

Concealed Duct Type Single type

562BT-E 802BT-E 1102BT-E 1402BT-E Outdoor unit

RAV SM562BT-E SM802BT-E

Under Ceiling Type Single type

562CT-E 802CT-E 1102CT-E 1402CT-E Outdoor unit

SM562CT-E SM802CT-E

SP1104ATZZG-E SP1404AZZG-E

High Wall Type Single type

RAV SM562KRT-E SM802KRT-E

SM562KRT-E SM802KRT-E

Compact 4-Way Cassette 600 × 600 Type Single type

RAV-SM562MUT-E

SP1104ZZG-E

Super Digital Inverter

Model name Outdoor unit

802ATZZG-E 1104ATZZG-E

Cooling Heating RAV-SP1404 RAV-SP1104

Operation characteristic curve Super Digital Inverter

Capacity variation ratio according to temperature

Cooling Heating

RAV-SM564UT-E

RAV-SM804UT-E

RAV-SM1104UT-E, RAV-SM1404UT-E

Name

Details of a

RAV-TWP30E2, RAV-TWP50E2 Simultaneous Twin

Model RBC

Single type Combination of 1 indoor unit and 1 outdoor unit

Twin type Combination of 2 indoor units and 1 outdoor unit

RAV-SP1104AT-E, RAV-SP1104ATZ-E, RAV-SP1104ATZG-E

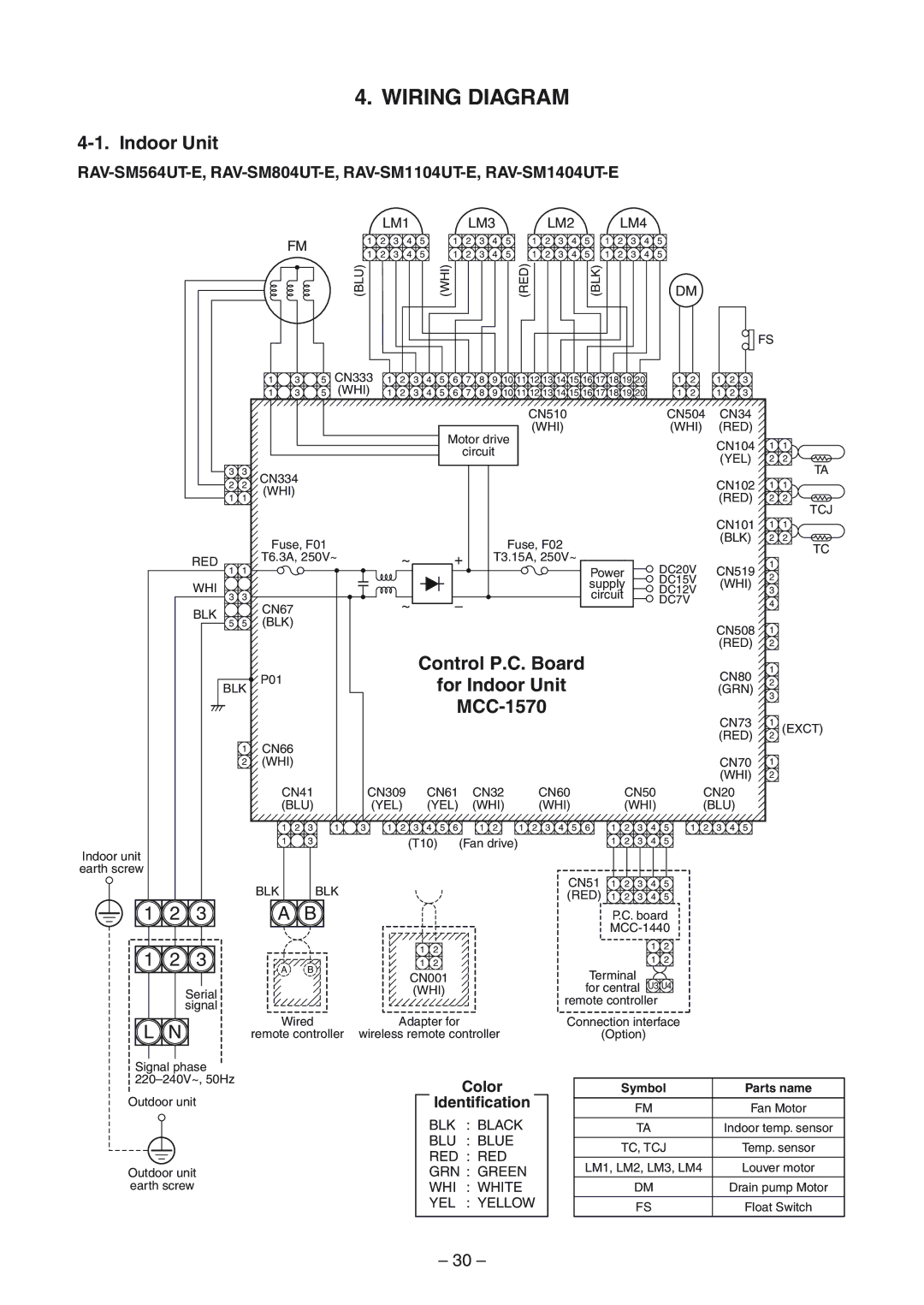

MCC-1570

Control P.C. Board

For Indoor Unit

Color

Symbol Parts name

Color Identification

Parts name Type Specifications

RBC-U31PGWS-E, RBC-U31PGW-E Ceiling panel

Safety During Installation/Servicing

Piping Materials and Joints Used

Outer diameter mm R410A R22

Processing of Piping Materials

1 Thicknesses of annealed copper pipes Thickness mm

Minimum thicknesses of socket joints

Outer Thickness Nominal Conventional flare tool

Flare and flare nut dimensions for R410A

Flare and flare nut dimensions for R22

Flare tool for

Nm kgfm

Wrenches available on the market

1 Configuration of refrigerant charging

Required Tools

Materials for Brazing Silver brazing filler

Low temperature brazing filler

Flux Reason why flux is necessary

Phosphor bronze brazing filler

Activated flux

Characteristics required for flux

Types of flux Noncorrosive flux

Piping materials for brazing and used brazing filler/flux

Curing of Pipes

Basic Conditions Need to Reuse the Existing Pipe

Branching Pipe for Simultaneous Operation System

Restricted Items to Use the Existing Pipes

Final Installation Checks

Existing pipe SW Switch

Operation method

When using existing pipe

Handling of Existing Pipe

Reference outside diameter Wall thickness

Indoor Controller Block Diagram

Connection of Main Sub Remote Controller

Connection of Wireless Remote Controller Kit

Wireless remote controller kit

Max units

Outline of specifications Remarks

Control outline Command

Setup data

Cool

Air speed

Conditions

Setup at shipment

Control temp. C

Individual air direction setup

Cooling/dry operation Heating/fan operation

All operations

Dual swing

Outline of specifications

Louver control Selection of Swing mode

Louver lock Louver fix

Selection of horizontal discharge position

Control which ignores lock Objective louver No

Filter

FAN

Louver

Mode

Function Connector No Pin No Specifications

Remarks

Indoor

Print Circuit Board

MCC-1570

Viewed from parts of P.C board

Outdoor Controls

Print Circuit Board

MCC-1571

Discharge temperature release control

Outline of Main Controls PMV Pulse Motor Valve control

Outdoor fan control

Cooling fan control

Heating fan control

Coil heating control

Short intermittent operation preventive control

Current release control

Over-current protective control

Temperature range SP110, SP140

Current release value shift control

High-pressure release control

Normal To Abnormal To

Defrost control

Start of heating operation

J805 J806

Troubleshooting procedure

Summary of Troubleshooting

Before troubleshooting

Wired remote controller type

Wireless remote controller type

Trouble Confirmation of lamp display

Troubleshooting

Outline of judgment

Lamp indication Check code Cause of trouble occurrence

Ready

Others Other than Check Code

Lamp indication Check code

Cause of trouble occurrence

Indoor unit detected

Check Code List Indoor

Remote controller detected

Central control devices detected

Check Code List Outdoor

Way valve inverse error

Indoor unit Heat exchanger sensor TCJ error

Error mode detected by indoor unit

Cause of operation Status

Cause of operation

Error mode detected by outdoor unit

Series

Operation of diagnostic function

E09 error

E04 error

E10 error

E18 error

E08, L03, L07, L08 error

L09 error

L20 error

L30 error

P30 error Central controller

P10 error

F10 error

P12 error

CN333 CN334

F02 error

F01 error

C06 error TCC-LINK central controller

E03 error Master indoor unit

F29 error

P31 error Follower indoor unit

Latest error display

Diagnostic Procedure for Each Check Code Outdoor Unit

LED display on outdoor P.C. board Dip switch setup

Error display, which occurs at present

Display Display 2 Heat exchanger temp. sensor TE error

F06

F12 Display 1 Display 2 Suction temp. sensor TS error

F13 Display Display 2 Heat sink temp. sensor TH error

F31 Display Eeprom error

H03 Display 1 Display 2 Current detection circuit error

H02 Display Compressor lock

L10 Display

Display Communication error between MCU

Is PMV Normal?

P05 Display Display 2 Power supply error Voltage error

Is refrigerant charge amount adequate? Recharge refrigerant

Replace defective part

P15 Display 1 Display 2 Gas leak detection

Exchange to cooling cycle Exchange to heating cycle

Loosening of outdoor fan?

Position detection circuit error

Single operation check for outdoor fan

P29

TA, TC, TCJ,TE, TS, to sensors

Temperature sensor

Temperature Resistance value characteristic table

TD, TL sensors

Replacement procedures

Indoort Unit

Contents

Setting data read out from Eeprom

C. Board for indoor unit servicing replacement procedures

100

Writing the setting data to Eeprom

Jumper wire J02

101

Eeprom layout diagram

102

Type Code No

Setting data Code No. table example

103

Indoor unit capacity Code No

Model switching J800 to J803

Outdoor Unit Setting the jumper wires and DIP switches

Installing the P.C. board

104

105

Test Run Setup on Remote Controller

Wired remote controller

Push

Return Dip switch of the sensor section as before

Use either Cool or Heat operation mode for test operation

Conditioner from the wireless remote controller

106

107

Case of wireless remote controller

Procedure Description

Test cooling operation Test heating operation

D503 Yellow Main bus communication

D501 Red

D403 Red

D504 Green Sub bus communication

Push button. OK if indication lights

Function Selection Setup

109

Pushing button returns the status to the normal stop status

110

Function selection item No. DN list

111

Setup method

Wiring and Setting of Remote Controller Control

When connected 2 remote controllers operate the twin

112

Monitor Function of Remote Controller Switch

113

114

By feed unit Automatic address judgment

Indoor unit power-ON sequence

115

Initial communication

TCC-LINK wiring connection

Setup at Local Site / Others

Microprocessor block diagram

Function

No. of wires

Wiring specifications

C. board switch SW01 setup

117

How to Set up Central Control Address Number

External view of P.C. board assembly

Address setup

Setup from remote controller at indoor unit side

119

Push SET Push Test to finish the setup

How to set up type of swing

Using Timer SET / buttons, select type of the swing

Swing setup code Louver operation

How to set louver lock Louver fix

How to clear louver lock

How to set contents of save operation

Refrigerant Recovery Control

Operation method

122

123

Service Support Function LED Display, Switch Operation

Outline

Operation part

124

Switch Function / Contents Refer

Others Selection of LED display SW800, SW803 operation

Display selection list

Error display

Error contents

125

126

127

Specific operation for maintenance check SW801, SW804

Operation when pushdown button switch SW801 is pushed

Specific operation

SW804 Operation when pushdown button switch SW801 is pushed

128

Address setup procedure

Item code Data at shipment Setup data range

129

130

Address Setup & Group Control

System configuration

Terminology

Only turning on source power supply Automatic completion

Automatic address example from unset address No miscabling

131

Manual setting from remote controller

132

Push Unit button

Procedure Push

133

To know the position of indoor unit body by address

Maintenance/Check list

134

Detachment

Procedure Remarks

135

Attachment

Part name Procedure

136

No. Part name Procedure

137

138

139

† Drain cap 1. Detachment

140

‡ Fan motor 1. Detachment

141

‡ Fan motor 2. Attachment

142

Drain pump 1. Detachment

143

Drain pan 1. Detachment

144

Procedure

145

146

‚ Discharge 1. Detachment

„ Replacement of 1. Control P.C. board

147

148

No. Part name Procedure Remarks

149

150

† Compressor 1. Removal of defective compressor

Vacuuming

151

† Compressor 2. Mounting of compressor

Refrigerant charge

152

‡ PMV coil 1. Detachment

Fan guard 1. Detachment

Exploded Views and Parts List

153

804UT-E 1104UT-E 1404UT-E

154

Location Description Model Name

564UT-E

403 404 405 401 402

155

156

303

319

U31PG W-E

157

AX31U W-E AX31U WS-E

16 6

158

159

Location Description Model Name

1104ATZ-E 1404ATZ-E 1104ATZG-E 1404ATZG-E

160

Description Model Name

1104AT-E 1404AT-E 1104ATZ-E 1404ATZ-E 1104ATZG-E 1404ATZG-E

Check of Concentration Limit

Toshiba Carrier Corporation