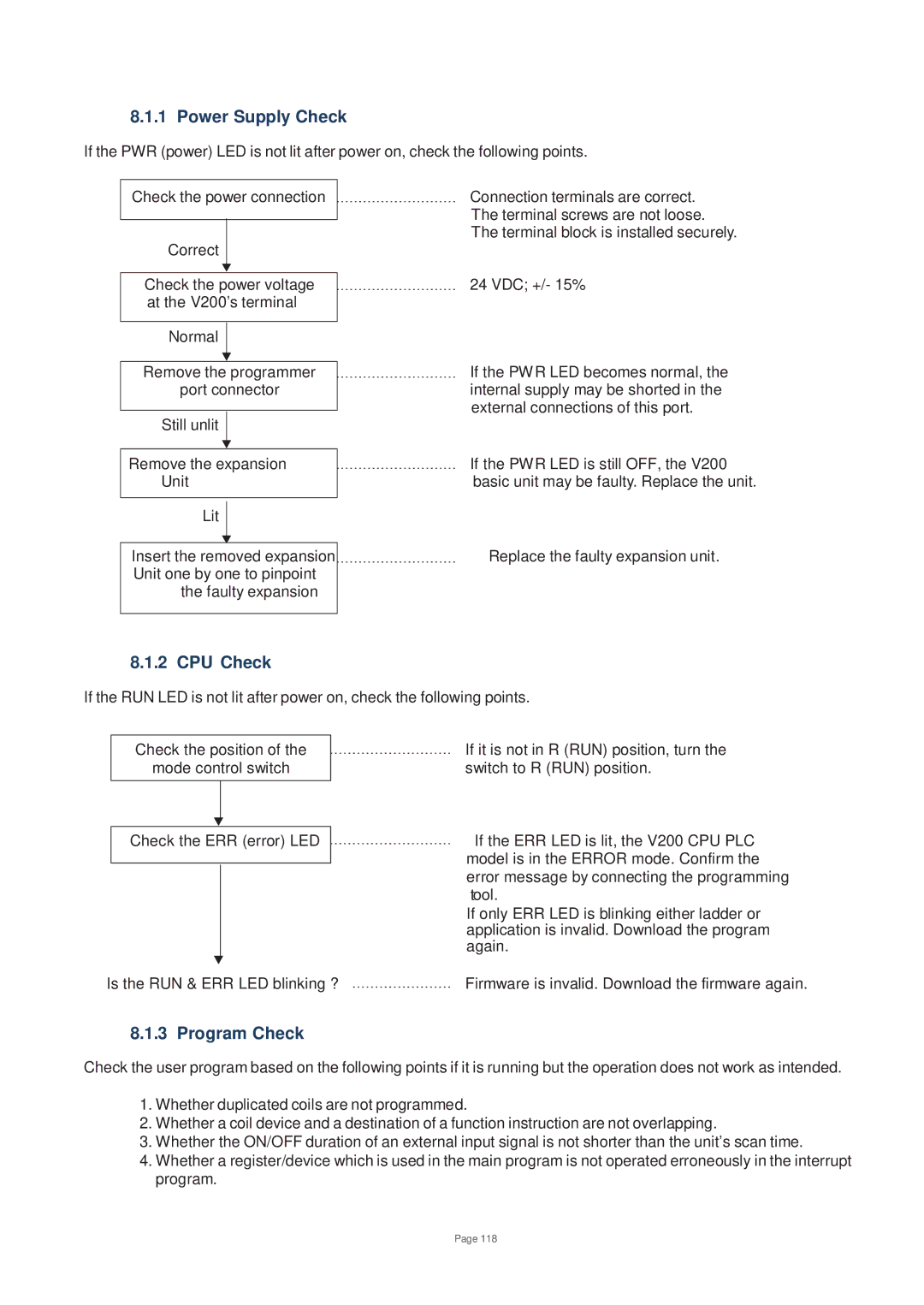

8.1.1 Power Supply Check

If the PWR (power) LED is not lit after power on, check the following points.

Check the power connection

Correct

Check the power voltage at the V200’s terminal

Normal

Remove the programmer

port connector

Still unlit

Remove the expansion Unit

Lit

Insert the removed expansion Unit one by one to pinpoint

the faulty expansion

Connection terminals are correct. The terminal screws are not loose. The terminal block is installed securely.

24 VDC; +/- 15%

If the PWR LED becomes normal, the internal supply may be shorted in the external connections of this port.

If the PWR LED is still OFF, the V200 basic unit may be faulty. Replace the unit.

Replace the faulty expansion unit.

8.1.2 CPU Check

If the RUN LED is not lit after power on, check the following points.

Check the position of the

mode control switch

Check the ERR (error) LED

If it is not in R (RUN) position, turn the switch to R (RUN) position.

If the ERR LED is lit, the V200 CPU PLC model is in the ERROR mode. Confirm the error message by connecting the programming tool.

If only ERR LED is blinking either ladder or application is invalid. Download the program again.

Is the RUN & ERR LED blinking ? | Firmware is invalid. Download the firmware again. |

8.1.3 Program Check

Check the user program based on the following points if it is running but the operation does not work as intended.

1.Whether duplicated coils are not programmed.

2.Whether a coil device and a destination of a function instruction are not overlapping.

3.Whether the ON/OFF duration of an external input signal is not shorter than the unit’s scan time.

4.Whether a register/device which is used in the main program is not operated erroneously in the interrupt program.

Page 118