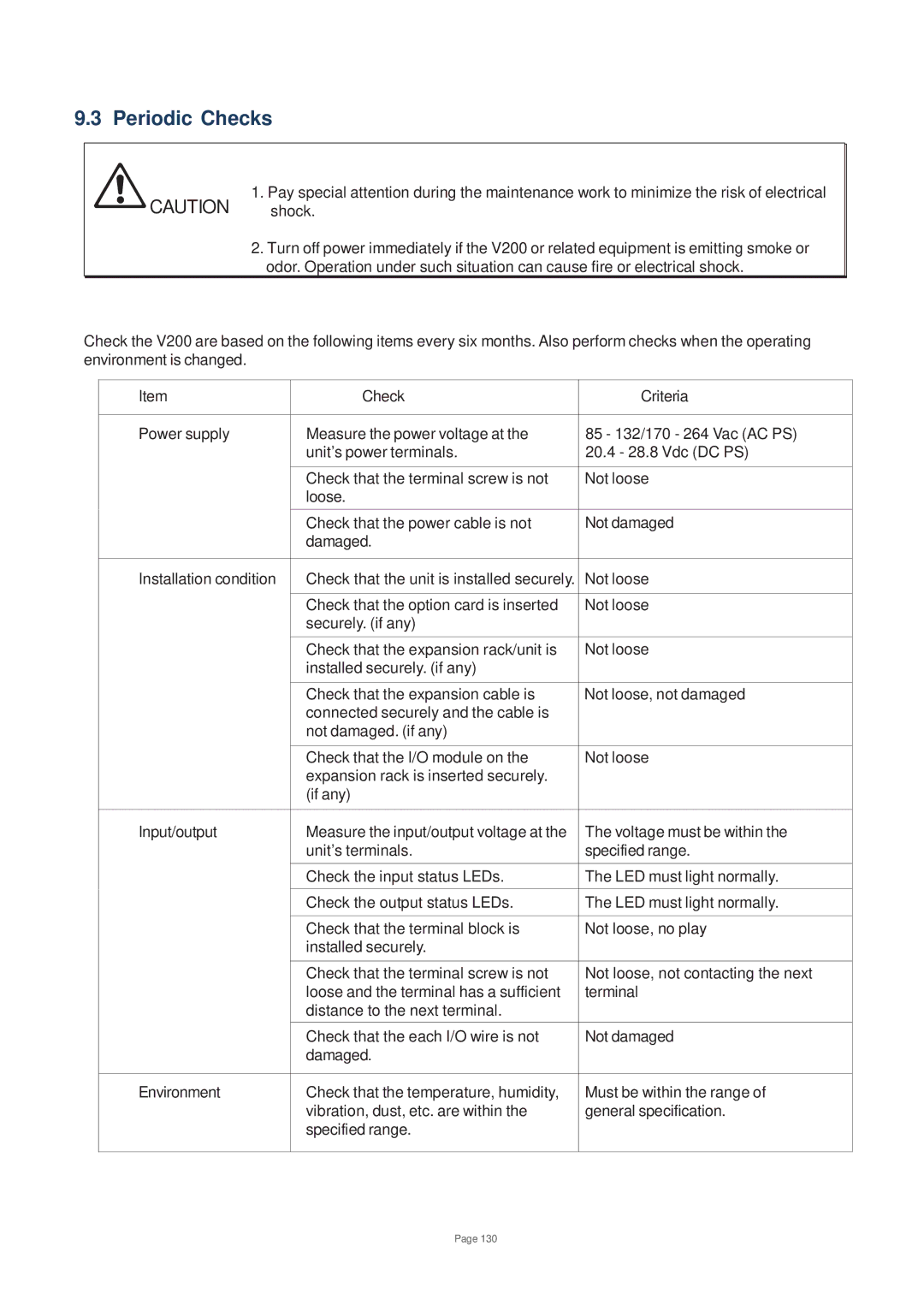

9.3 Periodic Checks

1. Pay special attention during the maintenance work to minimize the risk of electrical CAUTION shock.

2.Turn off power immediately if the V200 or related equipment is emitting smoke or odor. Operation under such situation can cause fire or electrical shock.

Check the V200 are based on the following items every six months. Also perform checks when the operating environment is changed.

Item | Check | Criteria |

|

|

|

Power supply | Measure the power voltage at the | 85 - 132/170 - 264 Vac (AC PS) |

| unit’s power terminals. | 20.4 - 28.8 Vdc (DC PS) |

|

|

|

| Check that the terminal screw is not | Not loose |

| loose. |

|

| Check that the power cable is not | Not damaged |

| damaged. |

|

|

|

|

Installation condition | Check that the unit is installed securely. | Not loose |

|

|

|

| Check that the option card is inserted | Not loose |

| securely. (if any) |

|

|

|

|

| Check that the expansion rack/unit is | Not loose |

| installed securely. (if any) |

|

|

|

|

| Check that the expansion cable is | Not loose, not damaged |

| connected securely and the cable is |

|

| not damaged. (if any) |

|

|

|

|

| Check that the I/O module on the | Not loose |

| expansion rack is inserted securely. |

|

| (if any) |

|

|

|

|

Input/output | Measure the input/output voltage at the | The voltage must be within the |

| unit’s terminals. | specified range. |

|

|

|

| Check the input status LEDs. | The LED must light normally. |

|

|

|

| Check the output status LEDs. | The LED must light normally. |

|

|

|

| Check that the terminal block is | Not loose, no play |

| installed securely. |

|

|

|

|

| Check that the terminal screw is not | Not loose, not contacting the next |

| loose and the terminal has a sufficient | terminal |

| distance to the next terminal. |

|

| Check that the each I/O wire is not | Not damaged |

| damaged. |

|

|

|

|

Environment | Check that the temperature, humidity, | Must be within the range of |

| vibration, dust, etc. are within the | general specification. |

| specified range. |

|

|

|

|

Page 130