| PROBLEM |

| POSSIBLE CAUSE | ACTION |

|

|

|

|

|

13. | CLOTHING |

| Excessive use of bleach | Instruct customer |

| DAMAGE |

| Overloading of machine | Instruct customer |

|

|

| Foreign objects | Remove |

|

|

| Water level too low | Increase water level |

|

|

| Agitates during spin | See problem 8 |

|

|

| Agitator surface rough | Replace agitator |

|

|

| Basket surface rough | Replace basket |

|

|

|

|

|

14. | GEARCASE |

| Leak at agitator shaft | Replace seal |

| LEAKS OIL |

| Leak at cover seal | Reseal |

|

|

| Too much oil in gearcase | Use only |

|

|

| Defective cover | Replace cover |

|

|

|

|

|

15. | WATER LEAKS |

| Use of low water level with high | Advise customer to use higher water |

|

|

| agitation | level |

|

|

| Leaking components | Repair or replace |

|

|

|

|

|

16. | BRAKE SQUEAL |

| Contaminated linings | Replace brake assembly |

|

|

|

|

|

COMPONENT TESTING

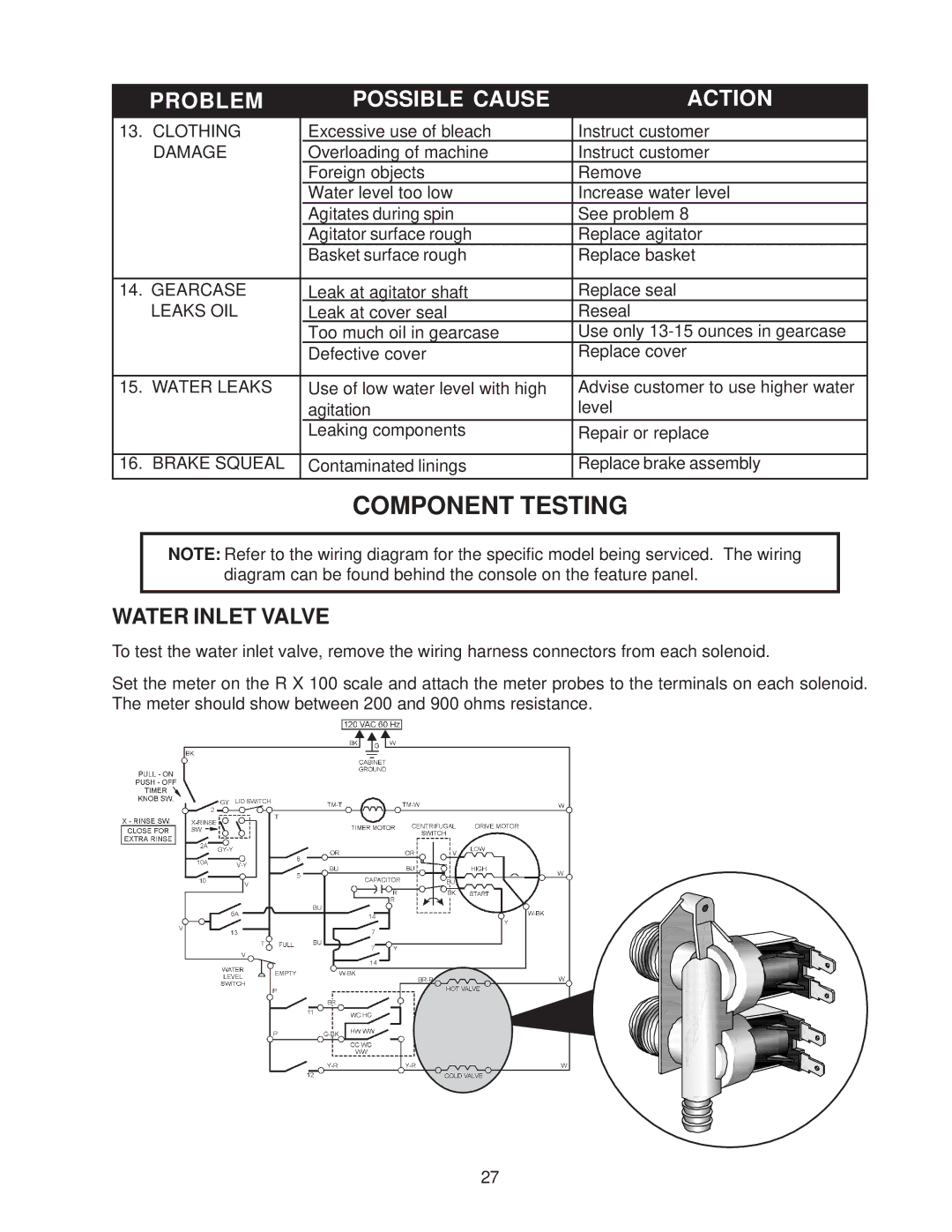

NOTE: Refer to the wiring diagram for the specific model being serviced. The wiring diagram can be found behind the console on the feature panel.

WATER INLET VALVE

To test the water inlet valve, remove the wiring harness connectors from each solenoid.

Set the meter on the R X 100 scale and attach the meter probes to the terminals on each solenoid. The meter should show between 200 and 900 ohms resistance.

27