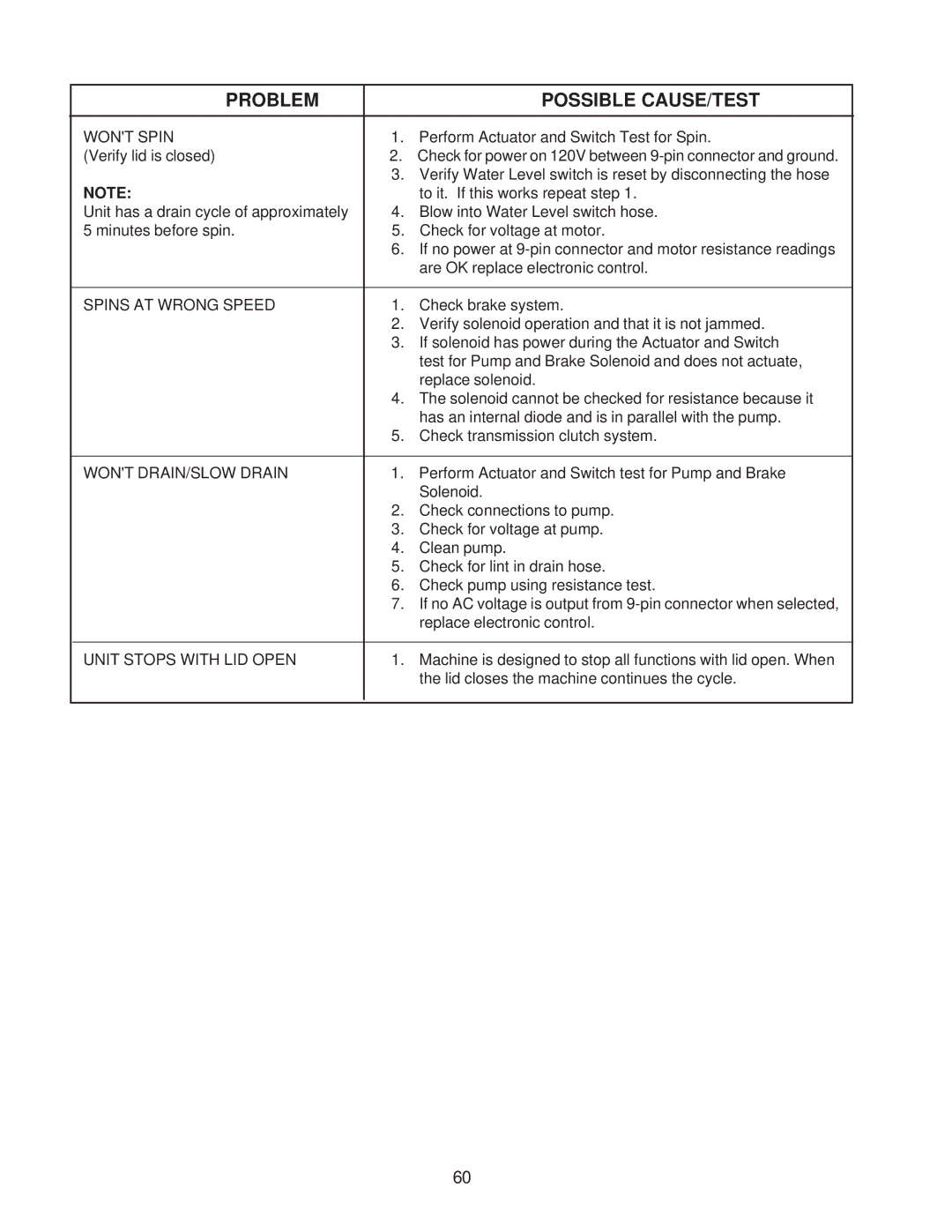

PROBLEM |

| POSSIBLE CAUSE/TEST |

|

|

|

WON'T SPIN | 1. | Perform Actuator and Switch Test for Spin. |

(Verify lid is closed) | 2. | Check for power on 120V between |

| 3. | Verify Water Level switch is reset by disconnecting the hose |

NOTE: |

| to it. If this works repeat step 1. |

Unit has a drain cycle of approximately | 4. | Blow into Water Level switch hose. |

5 minutes before spin. | 5. | Check for voltage at motor. |

| 6. | If no power at |

|

| are OK replace electronic control. |

|

|

|

SPINS AT WRONG SPEED | 1. | Check brake system. |

| 2. | Verify solenoid operation and that it is not jammed. |

| 3. | If solenoid has power during the Actuator and Switch |

|

| test for Pump and Brake Solenoid and does not actuate, |

|

| replace solenoid. |

| 4. | The solenoid cannot be checked for resistance because it |

|

| has an internal diode and is in parallel with the pump. |

| 5. | Check transmission clutch system. |

|

|

|

WON'T DRAIN/SLOW DRAIN | 1. | Perform Actuator and Switch test for Pump and Brake |

|

| Solenoid. |

| 2. | Check connections to pump. |

| 3. | Check for voltage at pump. |

| 4. | Clean pump. |

| 5. | Check for lint in drain hose. |

| 6. | Check pump using resistance test. |

| 7. | If no AC voltage is output from |

|

| replace electronic control. |

|

|

|

UNIT STOPS WITH LID OPEN | 1. | Machine is designed to stop all functions with lid open. When |

|

| the lid closes the machine continues the cycle. |

|

|

|

|

|

|

60